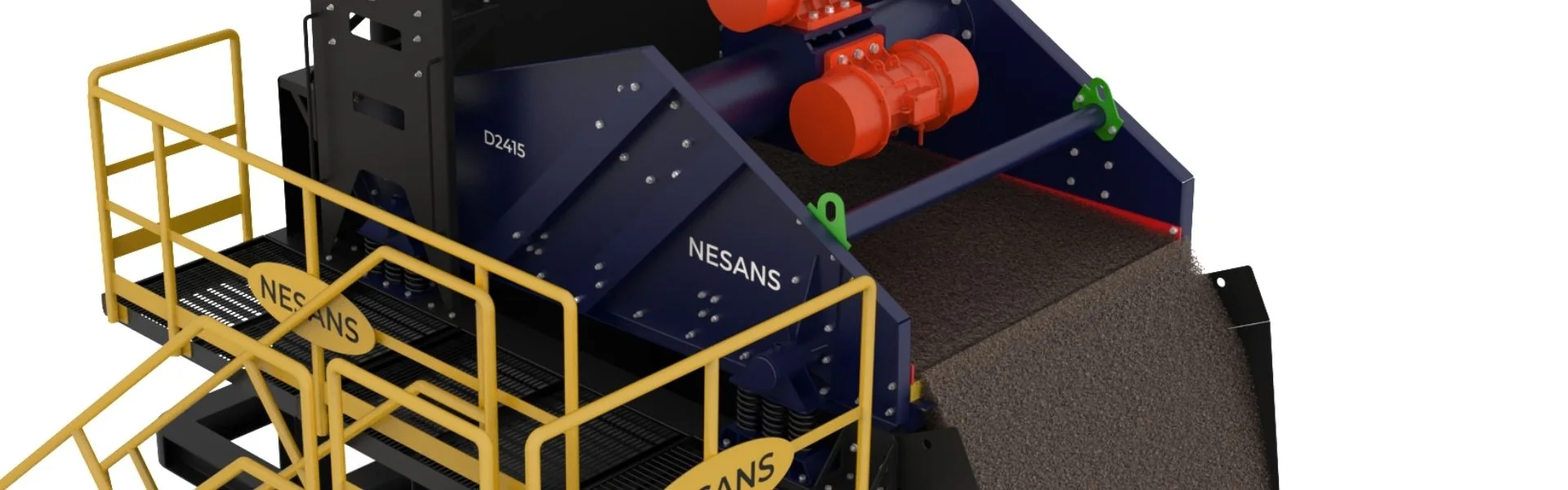

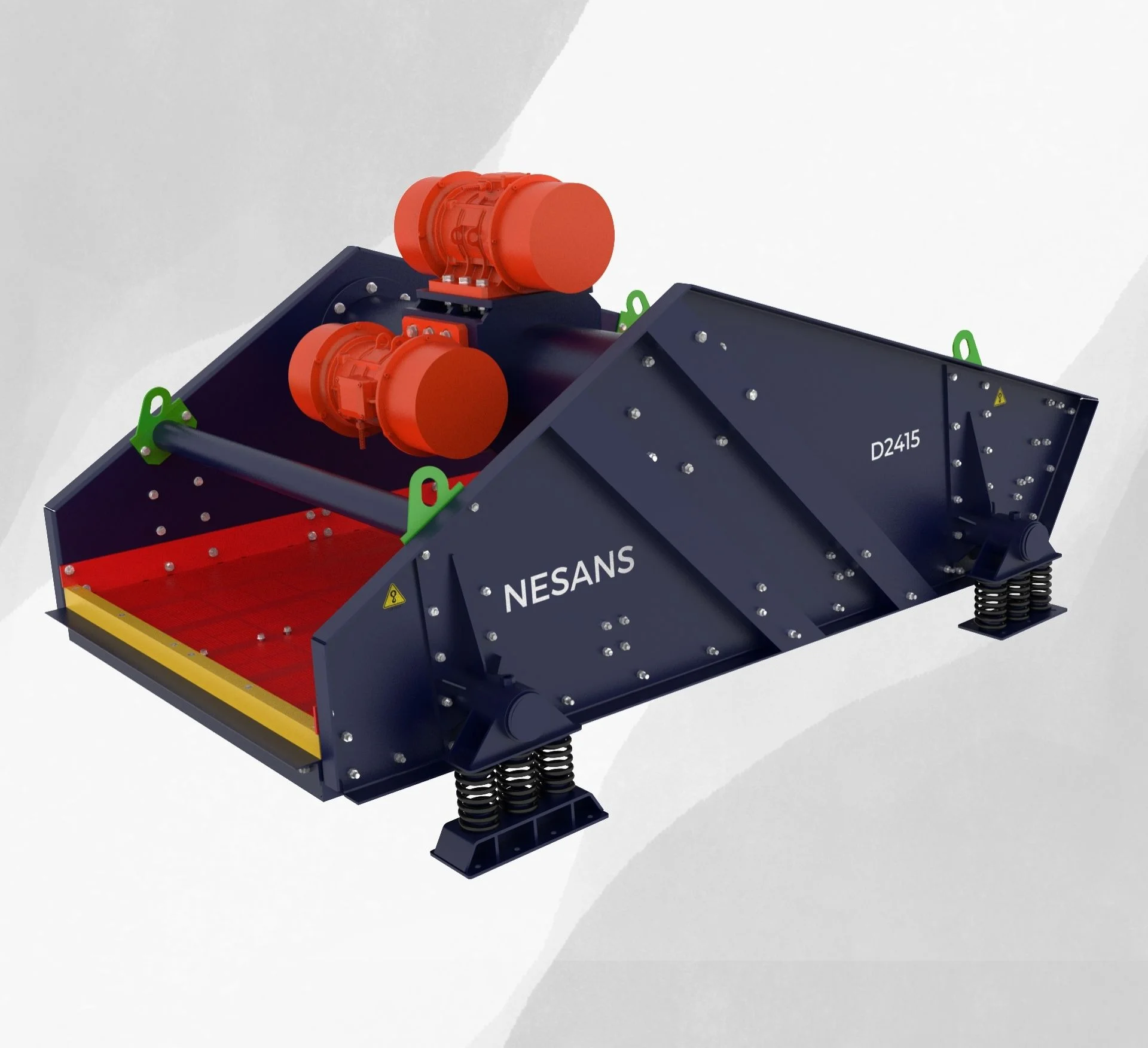

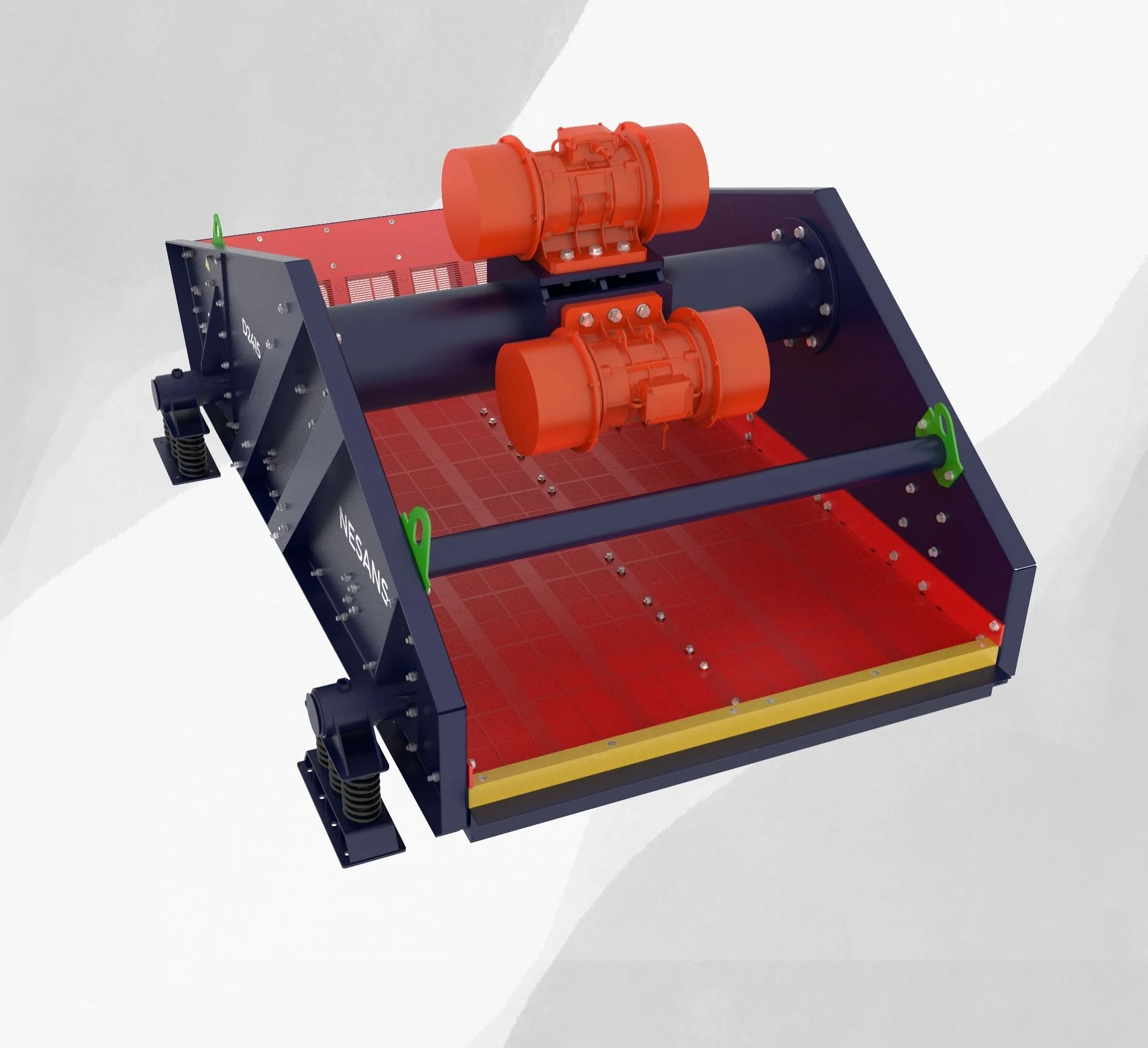

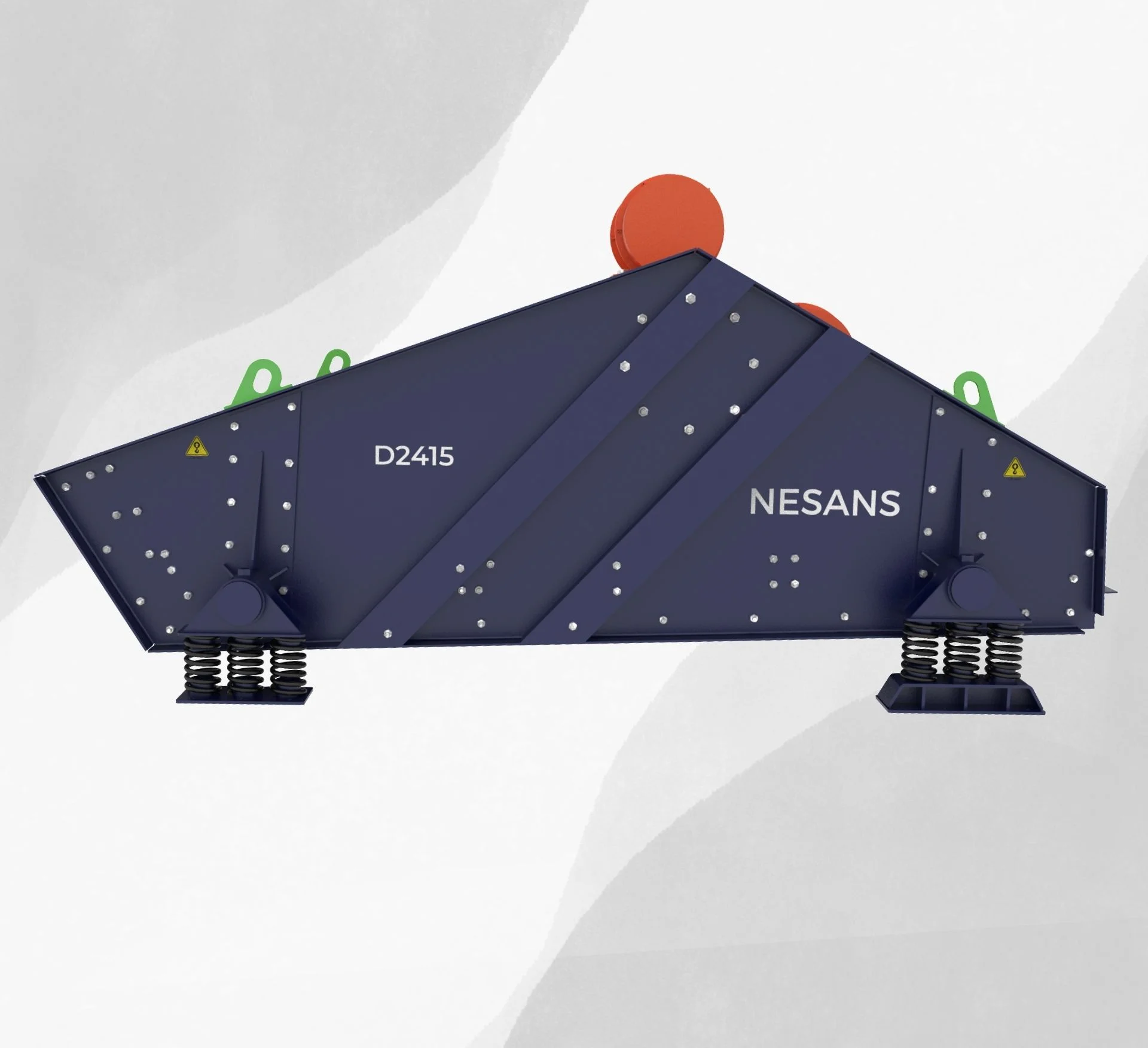

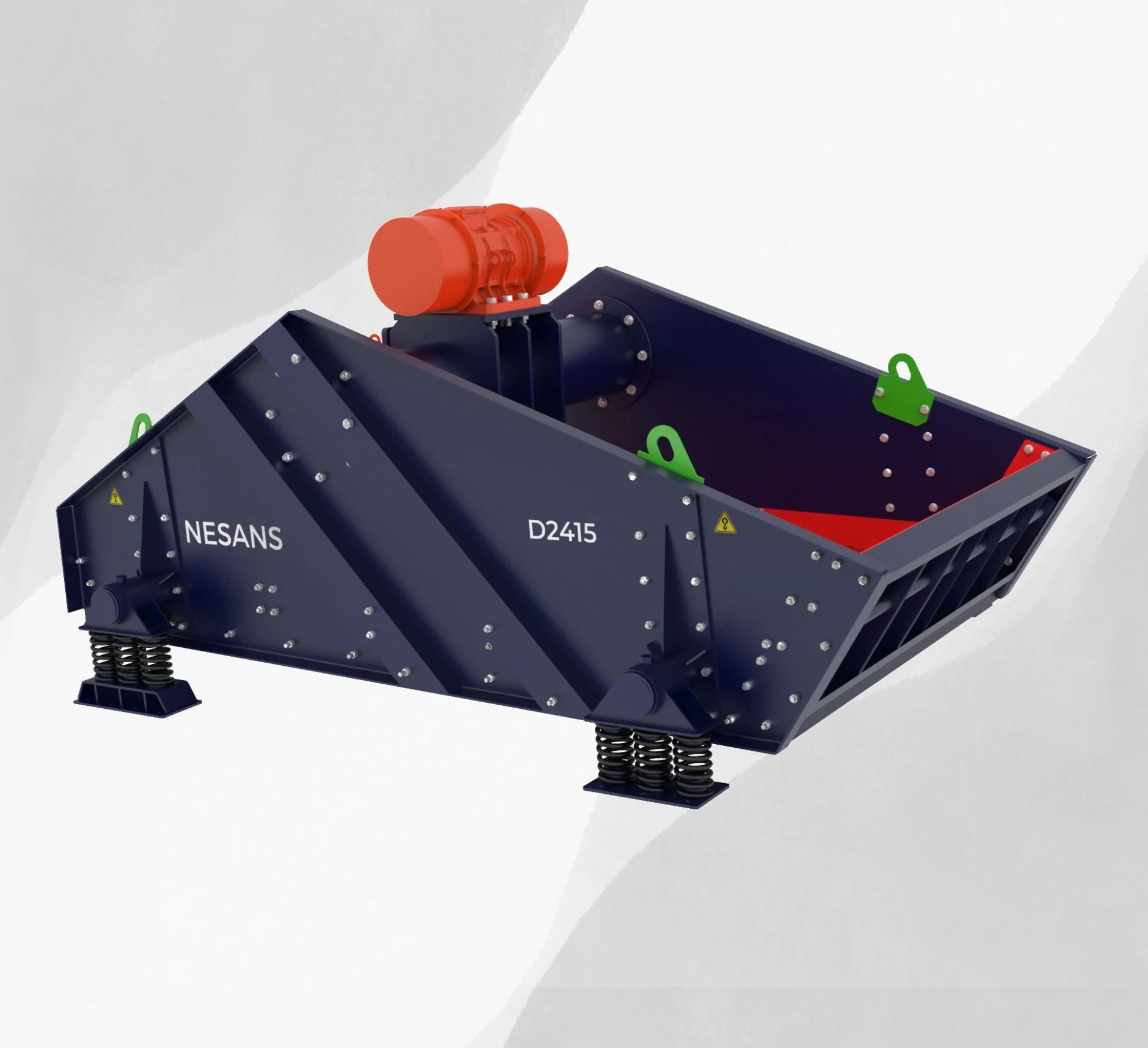

Dewatering Screen - D Series

The Nesans D Series Dewatering Screens are purpose-built for efficient moisture removal from washed sand, minerals, and other fine materials. Designed to deliver high drainage rates and minimal material loss, these screens are an essential component in any wet processing setup, ensuring clean, dry output suitable for storage or further processing.

With a compact footprint and high-frequency linear motion, the D Series delivers superior dewatering performance while maintaining structural integrity even under continuous heavy loads. Its rugged design, steep deck angle, and optimized screen media work together to maximize water removal and reduce cycle times.

Ideal for sand plants, mineral beneficiation, and industrial washing systems, the Nesans D Series offers consistent performance, low maintenance, and reliable operation, making it a trusted solution for achieving superior dewatering results.

Applications:

How It Works

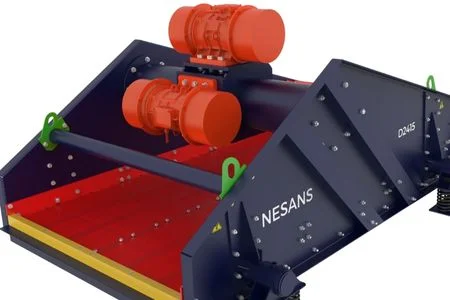

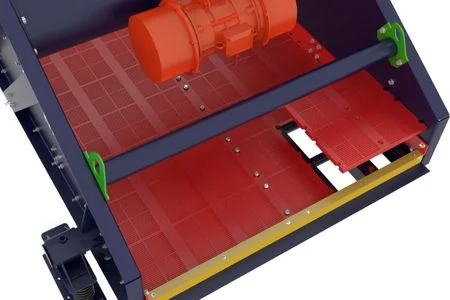

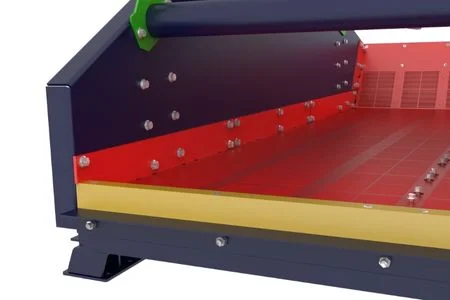

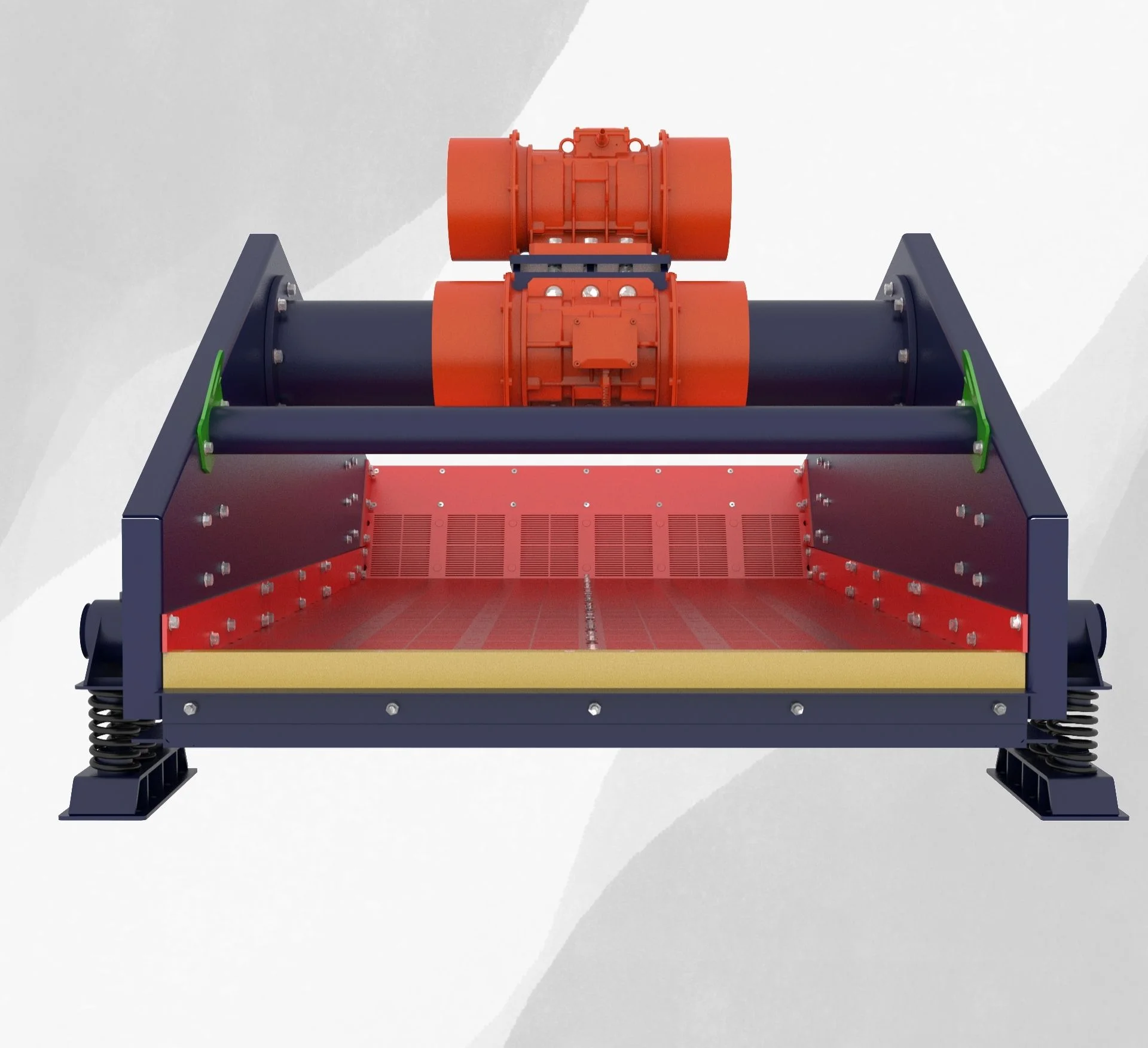

The Nesans D Series Dewatering Screens operate using high-frequency linear vibration to efficiently separate water from fine materials. Material is fed onto a steeply inclined screen deck where rapid vibration causes the particles to form a compact bed. As the bed moves across the screen, water is effectively drained through the screening media, leaving behind a moisture-reduced product.

The screen is typically powered by two counter-rotating vibratory motors that create a linear motion, pushing the material forward while continuously removing surface water. This motion, combined with the deck slope and high G-force, ensures maximum dewatering efficiency with minimal material loss. The result is a cleaner, drier product ready for immediate handling or storage.

Features and Advantages

Specifications

| Model No. | Max Length (mm) | Max Width (mm) | Max Feed Size (mm) | Dewatering Screen Power (kW) | Capacity (mtph) |

|---|---|---|---|---|---|

| D1206 | 1200 | 600 | -10 | 2 X 0.75 | 25 |

| D1209 | 1200 | 900 | -10 | 2 X 0.75 | 30 |

| D1809 | 1800 | 900 | -10 | 2 X 1.1 | 50 |

| D1812 | 1800 | 1200 | -10 | 2 X 1.6 | 65 |

| D2412 | 2400 | 1200 | -10 | 2 X 1.9 | 75 |

| D2415 | 2400 | 1500 | -10 | 2 X 2.2 | 100 |

| D3015 | 3000 | 1500 | -10 | 2 X 2.5 | 125 |

| D3612 | 3600 | 1200 | -10 | 2 X 3.7 | 150 |

| D3615 | 3600 | 1500 | -10 | 2 X 5 | 200 |

| D4215 | 4200 | 1500 | -10 | 2 X 7.5 | 250 |

| D4218 | 4200 | 1800 | -10 | 2 X 9.0 | 325 |

| Model No. | Max Length (ft) | Max Width (ft) | Max Feed Size (in) | Dewatering Screen Power (hp) | Capacity (stph) |

|---|---|---|---|---|---|

| D1206 | 4 | 2 | -1/2 | 1 | 28 |

| D1209 | 4 | 3 | -1/2 | 2 X 1 | 33 |

| D1809 | 6 | 3 | -1/2 | 1.5 | 55 |

| D1812 | 6 | 4 | -1/2 | 2 X 2 | 72 |

| D2412 | 8 | 4 | -1/2 | 2 X 2.5 | 83 |

| D2415 | 8 | 5 | -1/2 | 2 X 3 | 110 |

| D3015 | 10 | 5 | -1/2 | 2 X 3.5 | 138 |

| D3612 | 12 | 4 | -1/2 | 2 X 5 | 165 |

| D3615 | 12 | 5 | -1/2 | 2 X 7.5 | 220 |

| D4215 | 14 | 5 | -1/2 | 2 X 10 | 275 |

| D4218 | 14 | 6 | -1/2 | 2 X 12 | 358 |

Product Gallery

Relevant Products

FAQs

It uses high-frequency linear vibration, generated by two counter-rotating vibratory motors. Material is fed onto a steeply inclined deck, where rapid vibration compacts the material bed. Water drains through the screen media, leaving a drier product for storage or further processing.

Unlike standard screens, which focus on size separation, dewatering screens are optimized for water removal. The high G-force, steep deck angle, and fine screen media ensure maximum drainage with minimal material loss.

Yes. It efficiently dewaters silica sand, manufactured sand, mineral fines, and industrial solids, provided the feed is properly classified.

- Screen media (polyurethane or rubber panels).

- Motor bearings.

- Spring mounts and side liners (if handling abrasive material).

- Sand plants – dewatering washed M-Sand and river sand.

- Mineral beneficiation – drying coal, iron ore, and other fine ores.

- Industrial washing systems – removing water from recycled materials, slag, and other fines.

Depending on material type and feed conditions, It typically reduces sand and fines to 8–12% moisture content, suitable for direct stockpiling.

The motors produce synchronized linear motion that moves material forward steadily while maintaining consistent water removal.

The system can handle variable loads, but if feed slurry is too dilute, water carryover may increase. Pairing it with a hydrocyclone ensures steady feed density and best performance.

No. The machine is mounted on isolation springs, ensuring vibrations stay within the feeder body and do not damage surrounding structures.

Yes. By delivering a drier, cleaner product, it reduces load on stockyard drainage, conveyors, and water recovery systems, improving overall plant efficiency.

By producing a drier product, it eliminates the need for long stockpile drainage times and reduces rehandling or water recovery loads.

Dewatering Screen has a compact footprint, much smaller than settling ponds or thickeners, making it easy to integrate into existing washing circuits.

- Daily: Check for unusual noise or heating.

- Weekly: Inspect bolts and wiring.

- Monthly: Grease bearings as per schedule.

Both options work, but the best results come from combining the two:

- Hydrocyclone → removes ultra-fines and concentrates slurry.

- Dewatering screen → produces a drier, stackable product.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.