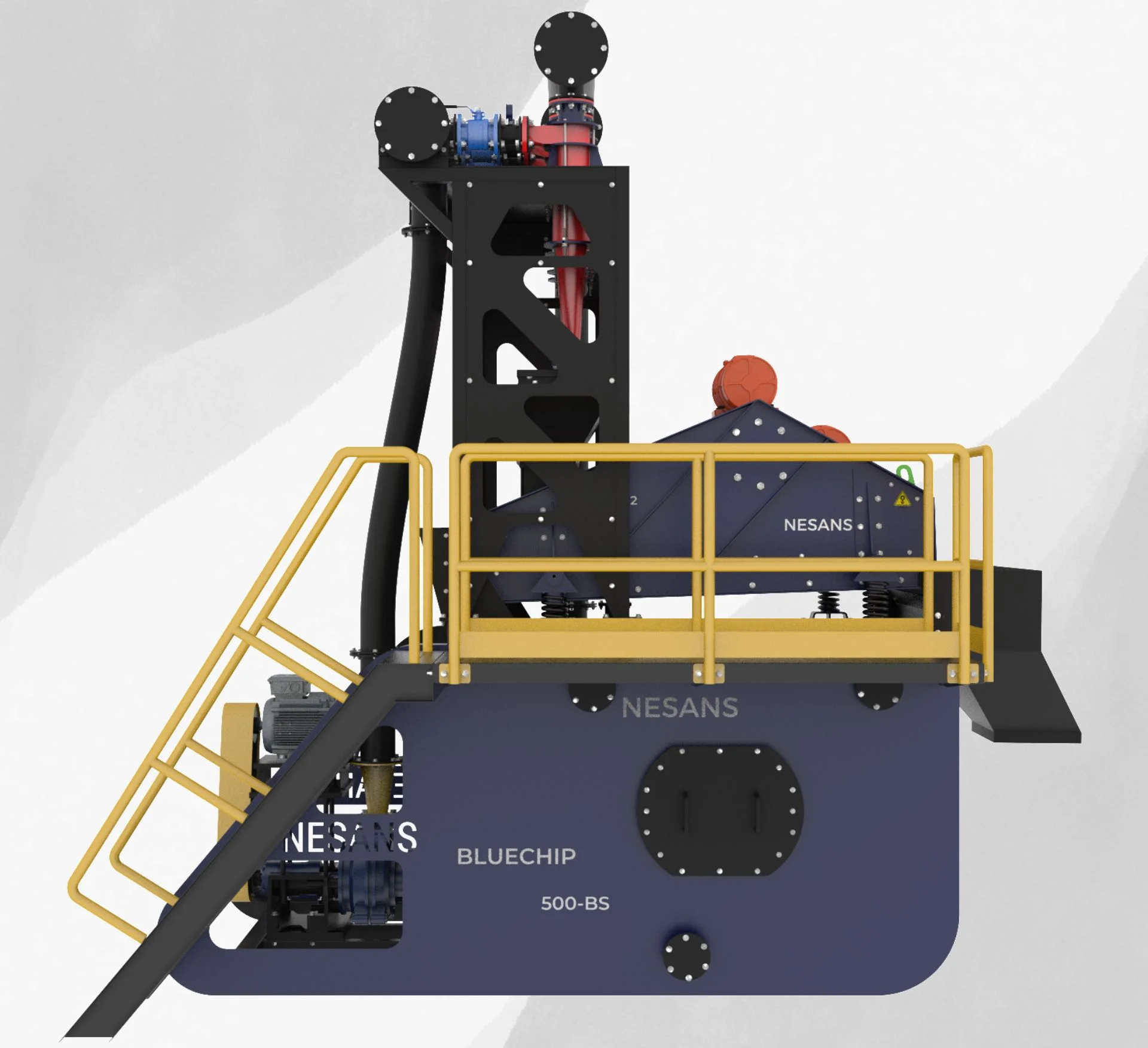

Super Fines Classifiers - Blue Chip Series

The Nesans Blue Chip Series Super Fines Classifier is a high-efficiency fines recovery system designed to reclaim valuable ultra-fine material lost from existing sand washers or classifiers. Acting as a post-processing unit, it captures the fines that typically escape into sedimentation tanks—turning process waste into usable plaster sand or filler material.

Built around a cluster of precision-engineered hydrocyclones, the Blue Chip Series uses centrifugal force to separate ultra-fine particles from slurry overflow streams. This makes it an ideal add-on solution for plants that suffer from poor fines recovery due to conventional washing equipment, helping to maximize resource utilization and reduce sludge generation.

With its compact footprint, energy-efficient operation, and easy retrofit design, the Blue Chip Series offers a cost-effective path to improved plant yield and environmental sustainability. It’s the preferred choice for operators who want to recover more, waste less, and get the most out of their existing setup.

Applications:

How It Works

The Nesans Blue Chip Series Super Fines Classifier operates on the principle of centrifugal classification using a hydrocyclone cluster. Slurry overflow from an existing sand washer or classifier—typically rich in ultra-fine particles—is diverted into the Blue Chip system. This slurry is then pumped under pressure into a bank of high-efficiency hydrocyclones.

Inside each cyclone, the slurry undergoes high-speed rotational flow, generating centrifugal forces that push heavier fine particles outward toward the cyclone walls. These usable fines are then discharged through the underflow, while lighter silt and unwanted ultra-fines exit via the overflow to waste or further water treatment.

The recovered underflow, rich in usable plaster sand or mineral fillers, can be routed to a dewatering screen or chute for final processing. This setup ensures maximum recovery of saleable material, reduced water loss, and lower sedimentation tank loading, making the Blue Chip Series an efficient and sustainable enhancement to any sand washing circuit.

Features and Advantages

Product Gallery

Relevant Products

FAQs

The classifier operates on the principle of centrifugal classification using a hydrocyclone cluster. Slurry overflow from your existing sand washer or classifier—usually rich in ultra-fine particles—is pumped into the Blue Chip system. Inside the cyclones, centrifugal forces push heavier usable fines outward, which are discharged through the underflow, while lighter silt and unwanted ultra-fines exit with the overflow to waste or water treatment.

It is typically placed after your sand washer or classifier. Instead of sending slurry overflow directly to waste ponds, you divert it to the Blue Chip system to recover usable fines.

Flow sequence:

Sand washer overflow → Slurry pump → Blue Chip Classifier (cyclone cluster) →

- Underflow (usable fines back to sand product line)

- Overflow (slimes → thickener/settling pond).

- Hydrocyclone liners.

- Apex (spigot).

- Vortex finder.

- Slurry pump parts (impeller, casing liner).

- Apex: when underflow becomes unstable or coarse cut is affected.

- Vortex finder: if fines bypass increases.

- Cyclone liners: when you notice reduced separation efficiency or visible wear.

- Pump parts: when pressure drops or leakage occurs.

Yes. By handling overflow streams or slurry from washing, it recovers usable fines that otherwise go to waste ponds.

Yes. By adjusting the cyclone apex and feed pressure, you can fine-tune the fines percentage that is recovered in underflow.

It uses the slurry from your washer overflow, so no extra fresh water is needed. The overflow from the Blue Chip can be directed to your thickener for water recovery.

No. While it is widely used in manufactured sand plants (M-Sand), it is equally effective in mineral processing, fly ash handling, slag classification, and industrial powder separation.

Using a superfine classifier offers a key advantage in product quality that a standard sand washer or bucket wheel washer cannot match. A sand washer is effective at removing coarse impurities, but it struggles to separate the very fine particles that are most detrimental to concrete. A superfine classifier acts as a polisher, precisely removing these harmful ultrafines and ensuring the manufactured sand is clean and properly graded for high-quality concrete production.

The classifier can handle some clay, but excessive sticky clay can cause slurry thickening and poor separation. In such cases, a pre-washing or scrubbing step is recommended before classification.

Yes. Since usable fines are recovered, only true slimes (<40 microns) go to ponds, reducing pond choking and desludging frequency.

- A single cyclone struggles with capacity fluctuations.

- A cluster ensures higher throughput, better efficiency, and more stable operation.

- Clusters can be run in parallel, so maintenance of one unit doesn’t stop the plant.

- Monitor cyclone underflow pattern.

- Check overflow clarity — cloudy water may indicate bypass.

- Inspect pump pressure and motor load.

- Check for leakage in pipelines and pump seals.

No. It works along with your washer/classifier to recover what they lose. Your washer handles washing and surface cleaning, while the Blue Chip focuses on fines recovery and precise classification.

- If your plant loses valuable fines into wash water.

- When you struggle to meet IS 383 Zone II/III sand gradation.

- If you want to recover saleable material from effluent streams.

- In plants where slimes content is high and requires controlled removal.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.