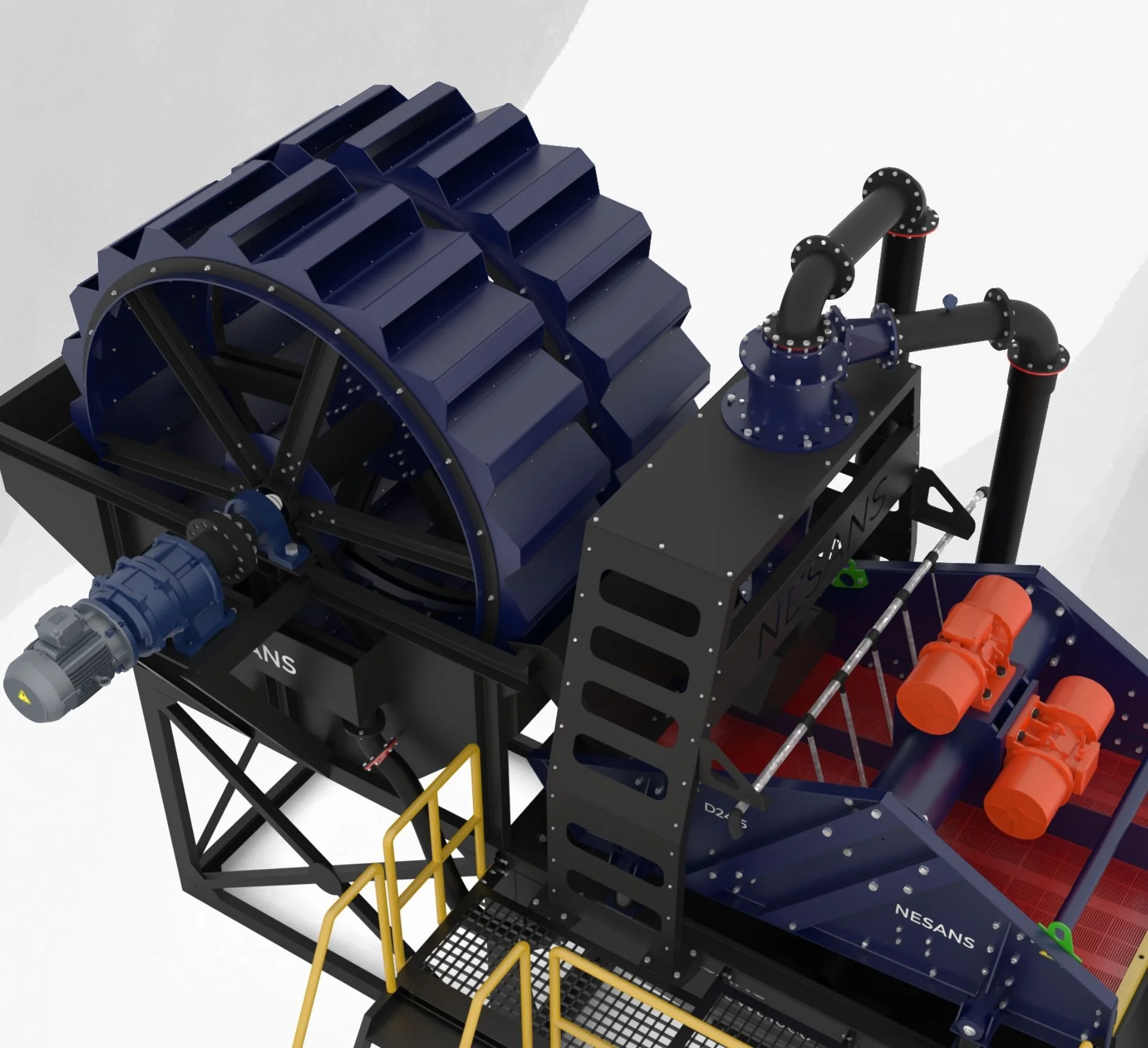

Hydrowash - SWE Series

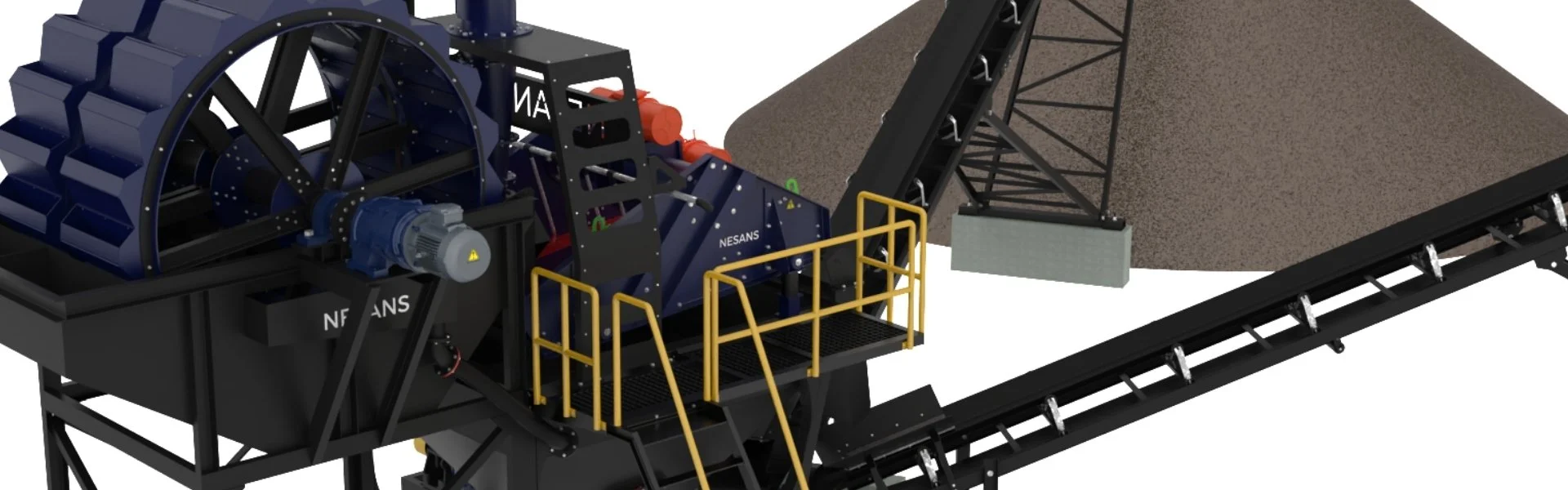

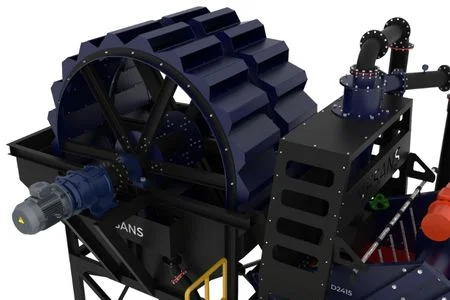

The Nesans SWE Series Hydrowash is a dual-stage sand washing system designed to deliver superior cleanliness and precise fines control in a single, integrated setup. Combining a bucket classifier for coarse material and a hydrocyclone system for fines recovery, the SWE Series offers a balanced solution that effectively handles a wide range of feed gradations and contamination levels.

In the first stage, coarse sand is separated and thoroughly washed in the bucket classifier, where unwanted silts and clays are removed through agitation and overflow. The fine particles along with the wash water are then transferred to the second stage—a hydrocyclone unit that efficiently recovers usable fines and reduces waste, ensuring minimal material loss.

Ideal for producers targeting high-quality plaster and concrete sand, the SWE Series provides clean, well-graded output with improved control over silt content. Its two-stage design not only enhances washing performance but also optimizes water usage and plant efficiency, making it a dependable choice for operations requiring consistent, spec-grade sand.

Applications:

How It Works

The Nesans SWE Series Hydrowash utilizes a two-stage washing process to maximize sand cleanliness and fines recovery. In the first stage, raw feed material is directed into a bucket classifier, where coarse sand particles are separated from the slurry. The buckets scoop up the heavier sand, allowing water and finer particles to overflow through a weir. As the buckets rotate, the coarse sand is gently washed and dewatered before being discharged.

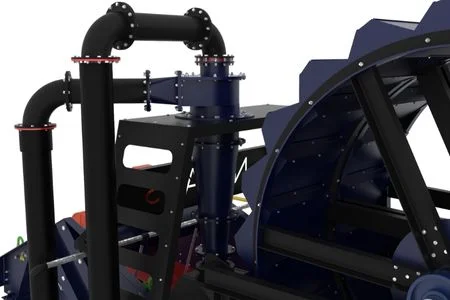

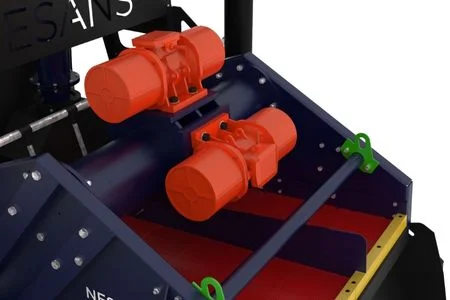

The overflow slurry, which contains suspended fines and silts, is then transferred to the second stage—a hydrocyclone system. Here, the slurry is pumped at high pressure into the cyclone, where centrifugal forces separate the fine sand from ultra-fines and clay. The recovered fines exit through the cyclone underflow and are sent to a dewatering screen, while the overflow, containing impurities, is directed to a settling area or water treatment circuit.

This dual-action setup ensures both efficient coarse sand cleaning and precise fine material classification, resulting in a high-quality, low-moisture sand product with minimal loss and optimal resource usage.

Features and Advantages

Specifications

| Model No. | Rotor Speed (rpm) | Pump Power (kW) | Max Feed Size (mm) | Drive Motor Power (kW) | Dewatering Screen Power (kW) | No of Cyclones (Nos) | Water Requirement (L/day) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|---|

| SWE750 - DUO | 3.6 | 10 | -5 | 3.75 | 2 x 1.5 | 1 | 15000 | 35 - 50 |

| SWE1000 - DUO | 3.6 | 15 | -5 | 5.625 | 2 X 2.2 | 1 | 20000 | 75 - 90 |

| SWE1500 - DUO | 3.6 | 30 | -5 | 7.5 | 2 X 3.7 | 2 | 25000 | 100 - 120 |

| SWE2000 - DUO | 3.2 | 40 | -5 | 11.25 | 2 X 5.5 | 2 | 30000 | 130 - 150 |

| SWE2500 - DUO | 3.2 | 45 | -5 | 15 | 2 X 5.5 | 2 | 35000 | 170 - 190 |

| Model No. | Rotor Speed (rpm) | Pump Power (hp) | Max Feed Size (in) | Drive Motor Power (HP) | Dewatering Screen Power (hp) | No of Cyclones (Nos) | Water Requirement (gal/day) | Capacity (stph) |

|---|---|---|---|---|---|---|---|---|

| SWE750 - DUO | 3.6 | 15 | -1/4 | 5 | 2 x 2 | 1 | 4000 | 33 - 61 |

| SWE1000 - DUO | 3.6 | 20 | -1/4 | 7.5 | 2 X 3 | 1 | 5000 | 83 - 99 |

| SWE1500 - DUO | 3.6 | 40 | -1/4 | 10 | 2 X 5 | 2 | 7000 | 110 - 132 |

| SWE2000 - DUO | 3.2 | 50 | -1/4 | 15 | 2 X 7.5 | 2 | 8000 | 143 - 165 |

| SWE2500 - DUO | 3.2 | 60 | -1/4 | 20 | 2 X 7.5 | 2 | 10000 | 187 - 209 |

Product Gallery

Relevant Products

FAQs

Hydrowash is a sand washing system combining a bucket classifier and a hydrocyclone unit to remove silt, clay, and fines producing clean, consistent, construction-grade sand.

The plant works in two stages:

- Bucket section removes coarse silt and recovers sand.

- Hydrocyclone system efficiently separates fines (<150 microns), producing cleaner, well-graded M-sand with controlled moisture.

Hydrowash (SWE) is installed right after screening, in the sand line. It connects directly to the undersize from your screen. This ensures fines removal and delivery of dewatered, sale-ready sand.

- Hydrocyclone liners

- Slurry pump impeller/liners

- Bucket paddles

- Dewatering screen meshes

Hydrowash processes:

- M-sand from crushers

- River sand

- Silica sand

- Crushed stone dust

It is versatile across quarrying, mining, and industrial applications.

Yes. However, if clay is sticky and excessive, a pre-wash or scrubbing system is recommended for better efficiency.

Water consumption depends on the feed material and capacity. Typically, Hydrowash uses 30–40% less water compared to conventional washing systems, thanks to its recycling arrangement.

No. Hydrowash is a compact plant, designed to occupy minimal space compared to traditional sand washing setups.

Hydrowash produces sand with low moisture (<12–15%), allowing faster drying, easier handling, and quicker dispatch.

Not always. A thickener or filter press is required only if you want zero discharge / dry slurry handling. For normal plants, a settling pond is sufficient.

- Screw classifier: High water loss, inconsistent fines removal.

- Hydrowash: Better fines control, low water use, higher recovery, compact footprint.

Operators should regularly monitor:

- Slurry pump impeller & liners for erosion

- Hydrocyclone rubber/ceramic liners for wear

- Bucket paddles & dewatering screen meshes for cracks or loosening

You’ll notice performance changes such as increased silt content in the output sand, reduced fines recovery, or unusual vibrations/noise from the slurry pump. These are early signs that hydrocyclone liners, pump impellers, or meshes may need replacement.

- RMC plants

- Asphalt batching plants

- Construction contractors

- Foundry & silica processors

- Quarry and mining operators

- High silt content in sand failing IS standards

- Loss of usable fines in screw classifiers

- Excess water content in washed sand

- High operating cost from older washing systems

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.