Envo Wash - SWF Series

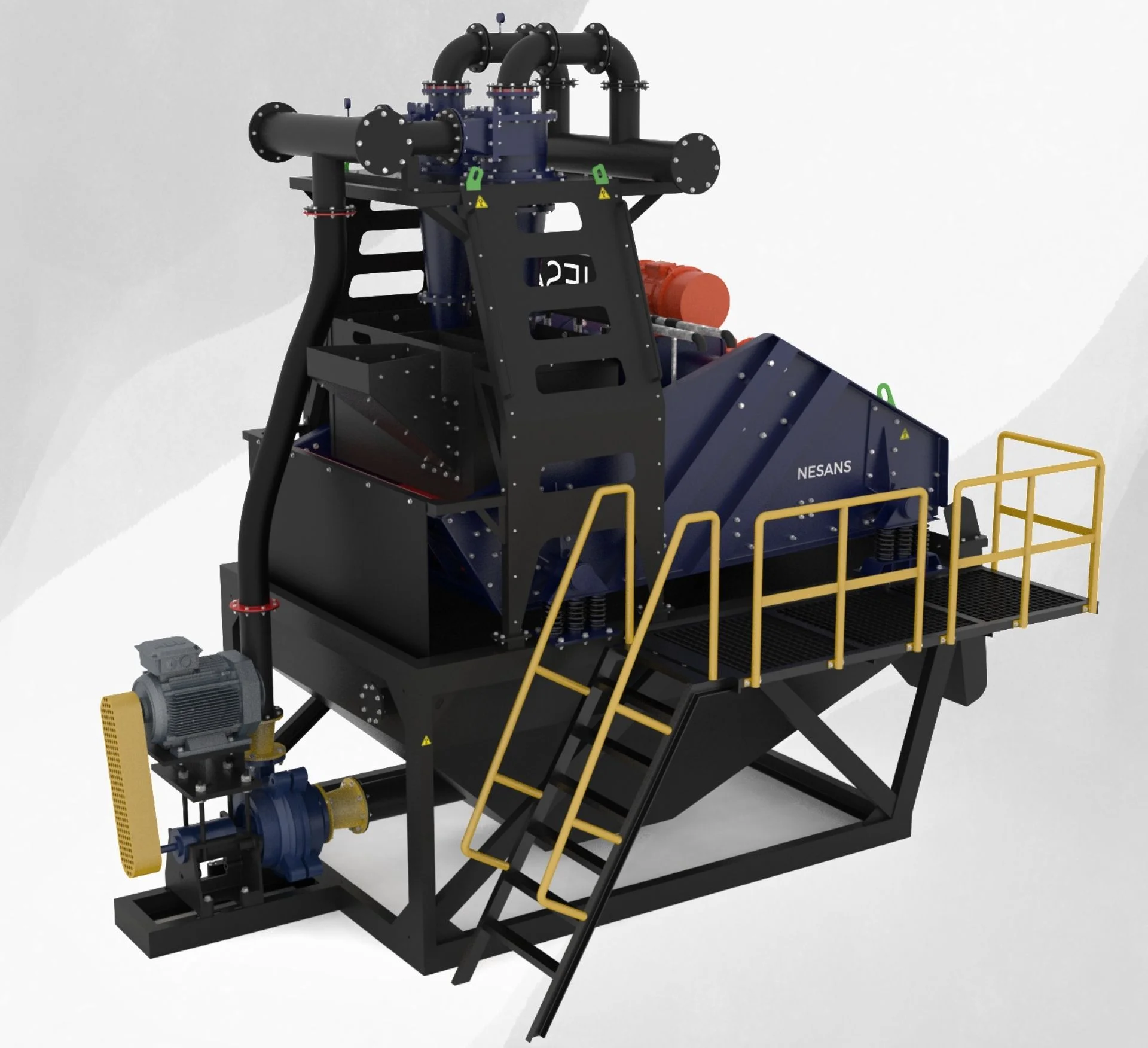

The Nesans SWF Series Envo Wash is a compact and efficient hydrocyclone-based washing system designed to deliver reliable performance in sand classification and fines recovery. Built on the foundation of proven cyclone technology, the SWF Series offers consistent removal of silt and clay impurities, producing clean, construction-grade sand ready for use in concrete, plastering, and block manufacturing.

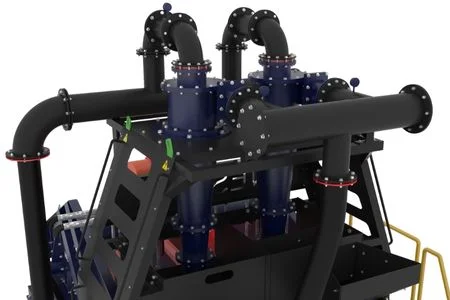

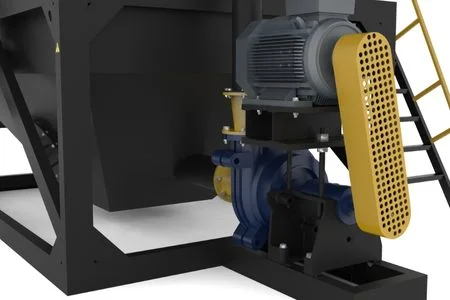

Featuring a simplified design with precision-engineered cyclones, integrated slurry pump, and dewatering screen, the Envo Wash ensures effective separation of fine particles while minimizing water and material loss. Its streamlined operation makes it easy to install, operate, and maintain, making it a practical solution for a variety of washing plant setups.

The SWF Series is ideal for manufacturers seeking a cost-effective solution without compromising on output quality. With dependable performance, reduced footprint, and minimal operational overhead, Envo Wash helps producers meet market standards while optimizing resource usage and overall plant efficiency.

Applications:

How It Works

The Nesans SWF Series Envo Wash operates on the principle of centrifugal sedimentation using hydrocyclone technology. Slurry containing sand, silt, and other fines is pumped into the hydrocyclone at high pressure. Inside the cyclone, centrifugal force drives the heavier sand particles downward to the underflow, while lighter fines and impurities are carried upward through the overflow.

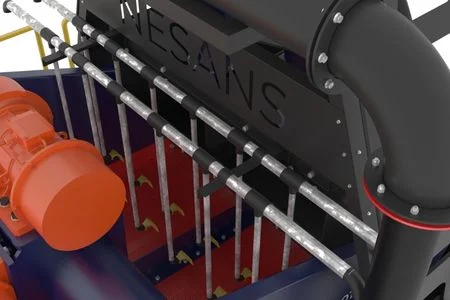

The underflow, which consists of clean, classified sand, is then discharged onto a dewatering screen, where excess water is removed, resulting in a low-moisture, ready-to-use sand product. The overflow water, carrying the fine impurities, is directed to a settling pit or wastewater treatment system, ensuring minimal material loss.

By combining cyclone classification with efficient dewatering, the SWF Series delivers clean sand with reduced water usage, making it an effective and streamlined solution for sand washing applications in various production environments.

Features and Advantages

Specifications

| Model No. | Flow Rate (m³/hr) | Pump Power (kW) | Max Feed Size (mm) | Dewatering Screen Power (kW) | No of Cyclones (Nos) | Water Requirement (L/day) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| SWF500 | 65 | 11 | -5 | 2 X 1.5 | 1 | 10,000 | 25 - 35 |

| SWF1000 | 130 | 15 | -5 | 2 X 2.2 | 1 | 20,000 | 65 - 75 |

| SWF1500 | 220 | 30 | -5 | 2 x 1.5 | 1 | 25000 | 90 - 110 |

| SWF2000 | 250 | 40 | -5 | 2 x 5.5 | 2 | 30000 | 120 - 160 |

| SWF2500 | 320 | 45 | -5 | 2 x 7.5 | 2 | 35000 | 175 - 210 |

| SWF3000 | 350 | 37.2 | -5 | 2 x 11.8 | 3 | 40000 | 200 - 250 |

| Model No. | Flow Rate (gpm) | Pump Power (hp) | Max Feed Size (in) | Dewatering Screen Power (hp) | No of Cyclones (Nos) | Water Requirement (gal/day) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| SWF500 | 216 | 15 | -1/4 | 2 X 2 | 1 | 3000 | 28 - 38 |

| SWF1000 | 572 | 20 | -1/4 | 2 X 3 | 1 | 5200 | 71 - 82 |

| SWF1500 | 800 | 40 | -1/4 | 2 x 5 | 1 | 7000 | 99 - 121 |

| SWF2000 | 1000 | 50 | -1/4 | 2 x 7.5 | 2 | 8000 | 132 - 176 |

| SWF2500 | 1200 | 60 | -1/4 | 2 x 10 | 2 | 9000 | 192 - 231 |

| SWF3000 | 1500 | 50 | -1/4 | 2 x 15 | 3 | 11000 | 220 - 276 |

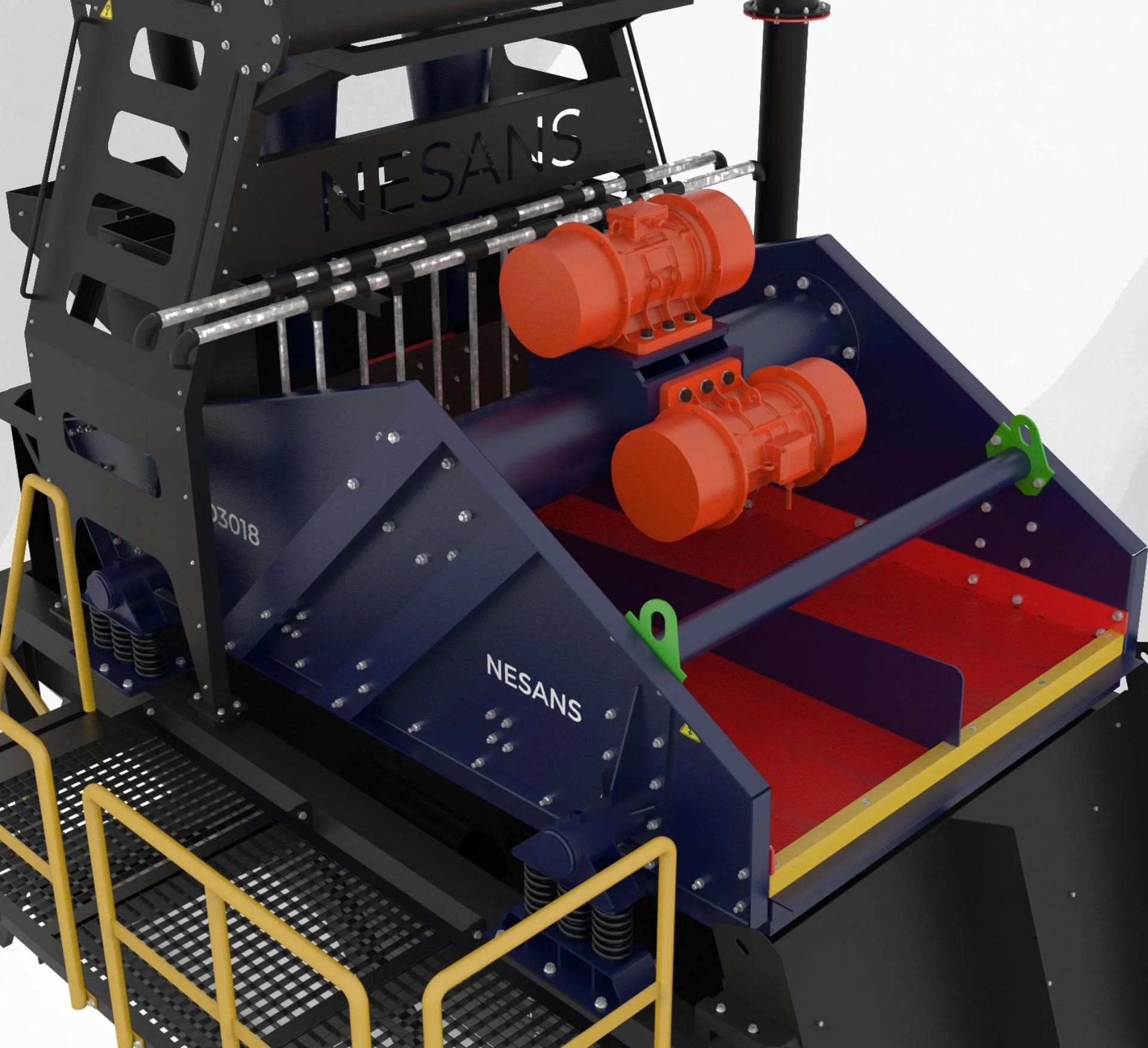

Product Gallery

Relevant Products

FAQs

Envo Wash is a compact sand washing plant that uses a hydrocyclone system to remove silt, clay, and ultra-fines from sand. It ensures consistent, high-quality M-sand with minimal water usage.

Feed slurry from the screen undersize is pumped into a hydrocyclone, where centrifugal force separates ultra-fines. Clean sand is then dewatered through a screen and stockpiled with low moisture content.

Envo Wash is placed right after the screening stage in the sand line:

Screen undersize → Slurry Pump → Hydrocyclone → Dewatering Screen → Stockpile.

Envo Wash is suitable for:

- Manufactured Sand (M-Sand)

- River Sand

- Silica Sand

- Quarry dust / crusher fines

- Hydrocyclone rubber/ceramic liners

- Slurry pump impellers and liners

- Dewatering screen meshes

The cyclone performs best when fed with slurry of 15–20% solids concentration, free from oversize or tramp material. Uniform feed helps maintain efficient separation and minimizes wear.

Typically, Envo Wash produces final sand with 10–12% moisture. This allows quicker drying, easier handling, and faster dispatch to RMC or construction sites.

- Envo Wash: Hydrocyclone-only system, highly compact, ideal for fine silt removal.

- Hydrowash: Combines bucket + hydrocyclone for higher recovery from coarse feed.

In a closed-loop plant (cyclone + thickener/clarifier), sites typically recover ~85–95% of process water.

If you observe sand quality dropping (more silt/fines in output) or reduced dewatering efficiency, it may be time to replace hydrocyclone liners, pump impellers, or screen meshes.

Run overflow to a thickener/clarifier; return recovered water to process and manage captured fines per your spec

- Excess fines/silt in sand making it unusable

- High water loss in screw classifiers

- Inconsistent sand quality from traditional washing systems

- Space and manpower constraints in sand washing

Envo Wash ensures better fines recovery, lower water usage, and consistent IS-compliant sand quality. Traditional screw classifiers and bucket washers often lose usable fines and consume excess water, leading to poor-quality sand and higher costs.

Delaying maintenance can lead to poor sand quality, excessive fines in overflow, high energy consumption, and sudden breakdowns that may damage critical components.

- Daily: Check slurry pump seals, cyclone apex condition, and screen tension.

- Weekly: Inspect cyclone liners, pump liners, and slurry density.

- Monthly: Check for abnormal vibrations, replace worn parts if needed.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.