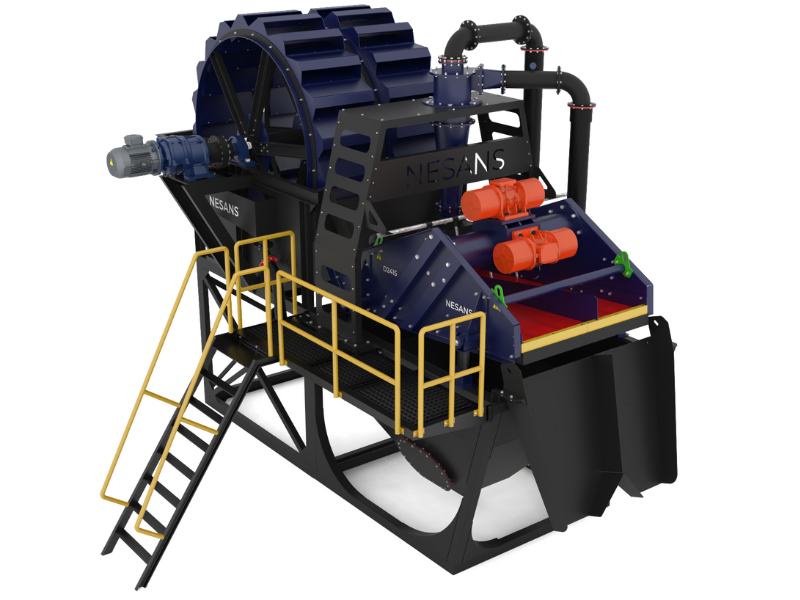

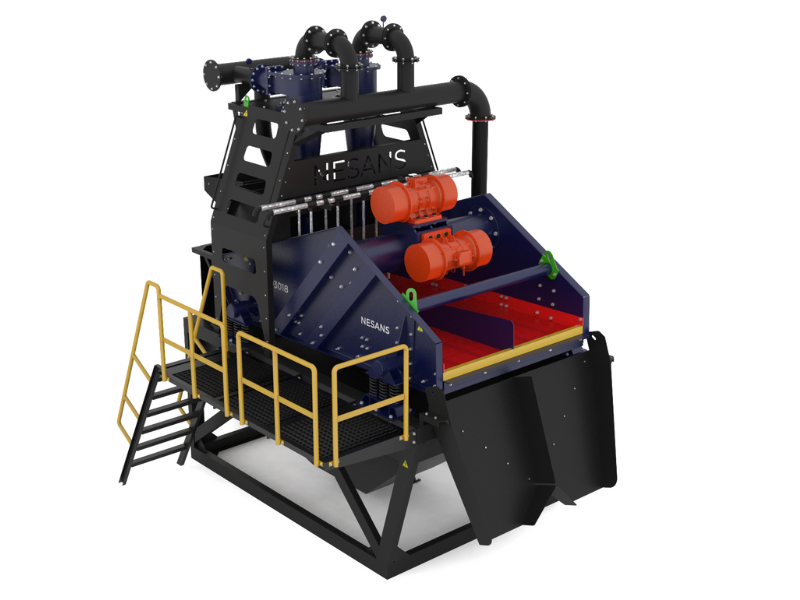

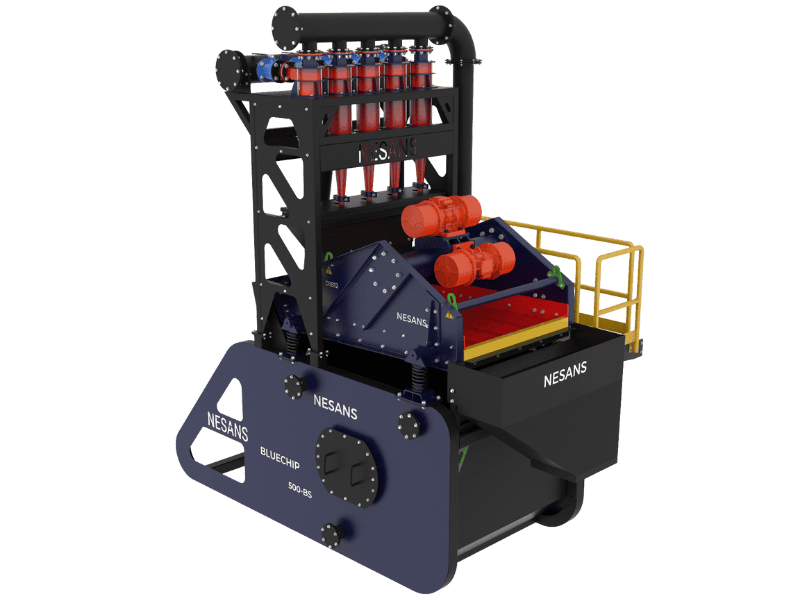

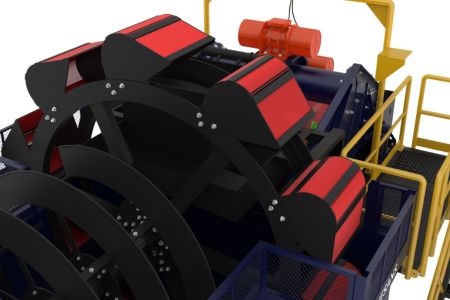

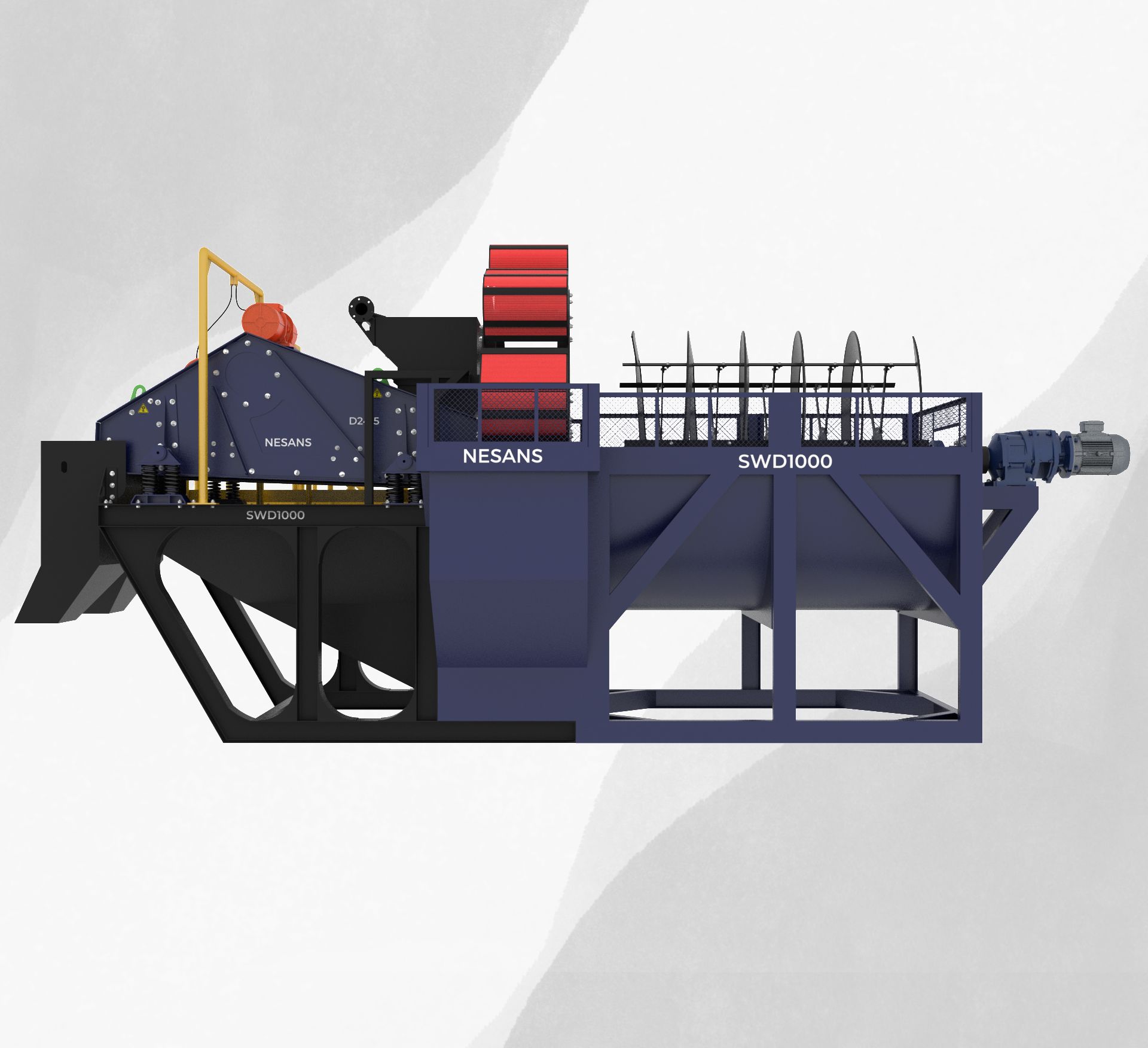

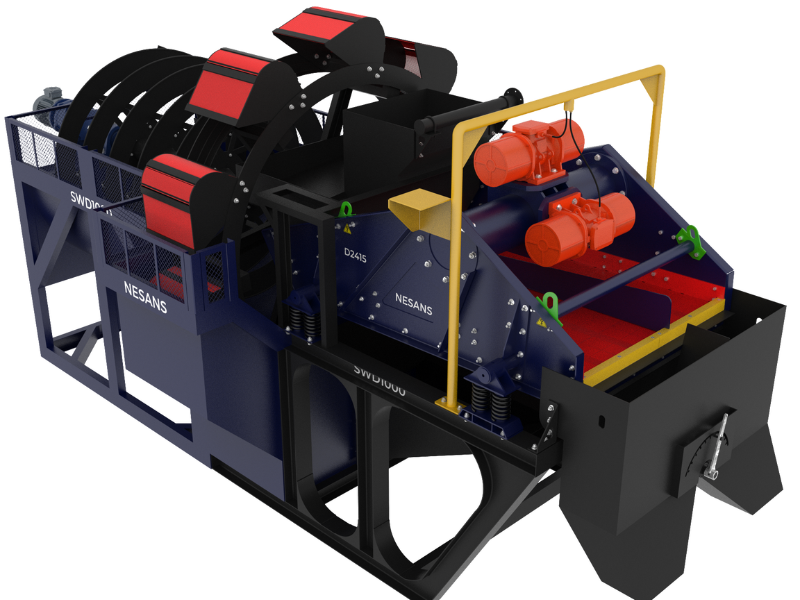

Bucket Sand Washer - SWD Series

The Nesans SWD Series Bucket Sand Washer is a robust and efficient sand cleaning system designed to remove silt, clay, and other impurities from coarse aggregates. Utilizing a slow-rotating bucket wheel mechanism, the machine ensures gentle scrubbing and effective separation of contaminants, delivering a clean, dewatered sand product suitable for a variety of construction applications.

One of the key advantages of the SWD Series is its ability to produce dual-grade sand. By separating heavier coarse particles from lighter fines during the washing cycle, the system enables producers to recover two distinct fractions of sand in a single operation—making it ideal for applications requiring both plaster and concrete-grade outputs. This feature adds significant value and flexibility to operations with diverse sand quality requirements.

Built for long-term performance, the SWD Series features a simple design with low wear and energy consumption, minimizing maintenance and operational costs. Whether used as a standalone washer or integrated into a larger sand processing plant, it offers dependable, low-footprint performance while maintaining consistent sand quality and maximizing usable yield.

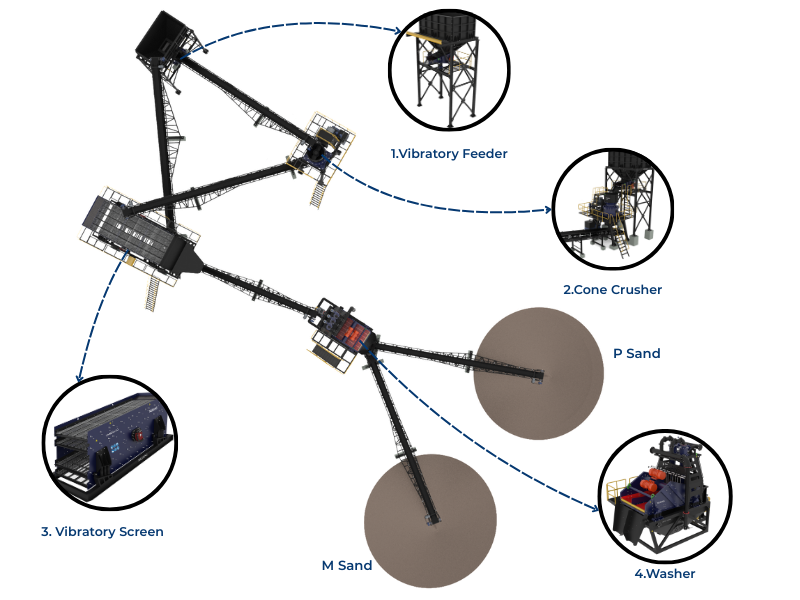

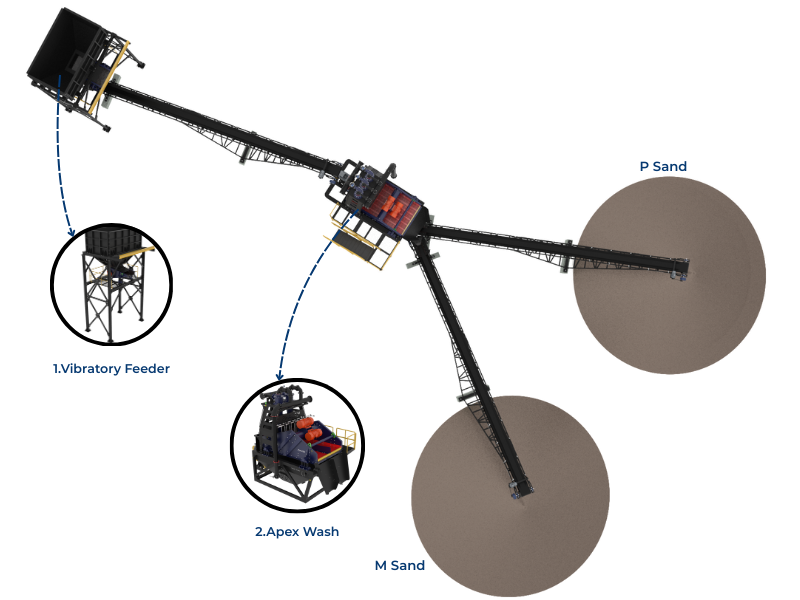

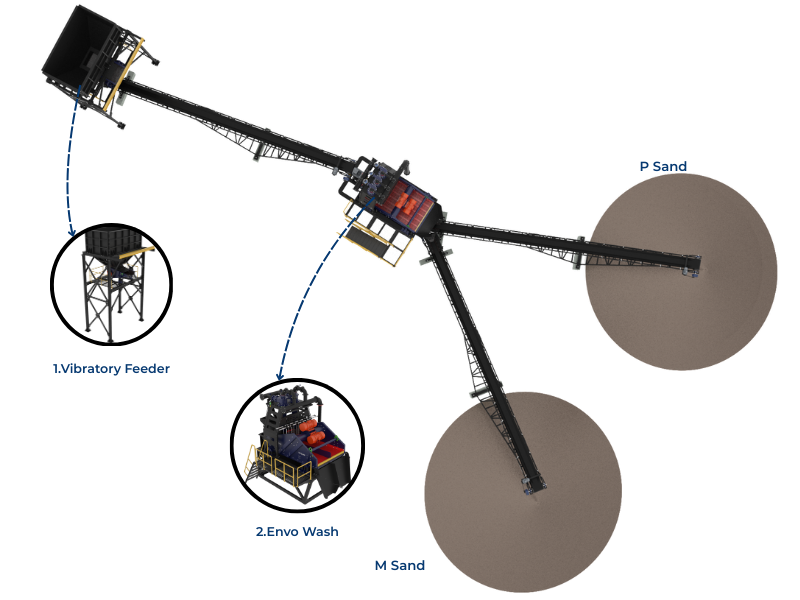

Applications:

How It Works

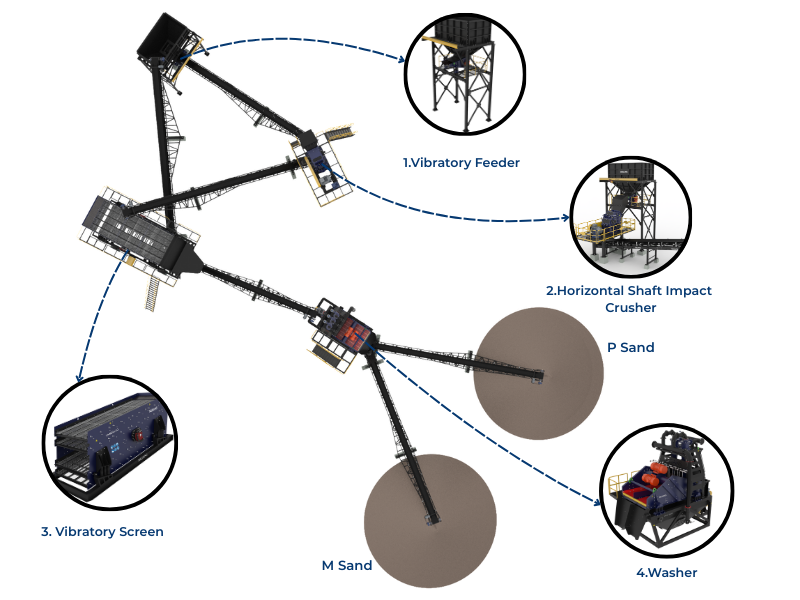

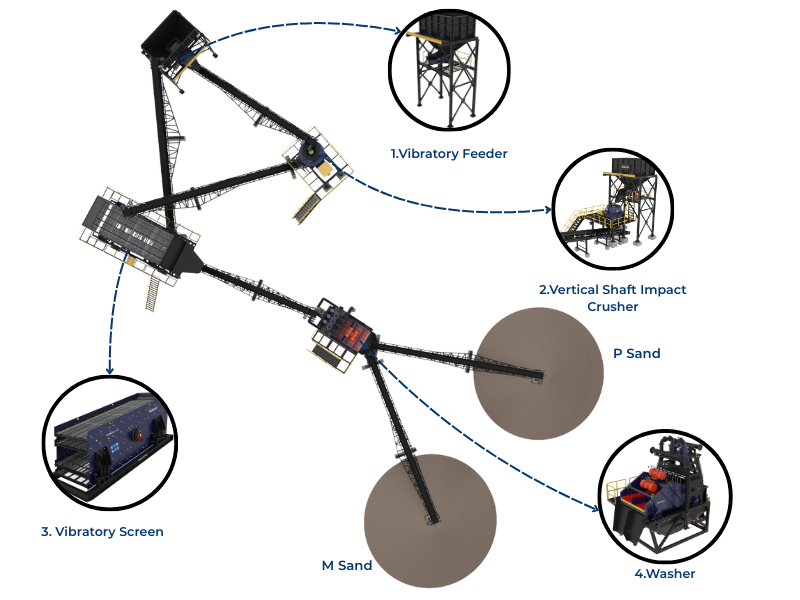

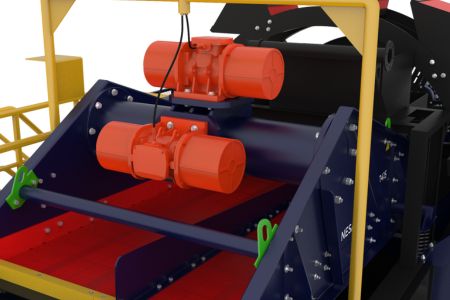

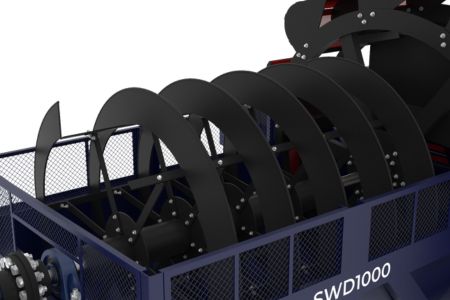

The Nesans SWD Series operates through a mechanical scrubbing and dewatering cycle using a rotating bucket wheel and a specially designed screw guide. When slurry enters the water tank, heavier sand particles settle at the bottom while lighter silt and clay remain suspended. A slow-rotating bucket assembly gently scoops the settled sand, allowing excess water to drain through the perforations before the sand is discharged as the primary, clean product.

During this process, some coarse particles may settle away from the bucket pickup path and risk being carried away with the overflow. To prevent this, a screw guide is positioned at the bottom of the tank, continuously pushing these settled particles back into the active washing zone, ensuring maximum sand recovery and minimal material loss.

Meanwhile, the overflow water carrying fines and impurities is safely discharged from the weir section, completing the washing cycle. This combination of gentle bucket action and coarse recovery via the screw ensures consistent sand quality, dual-grade separation, and efficient resource utilization.

Features and Advantages

Specifications

| Model No. | Rotor Speed (rpm) | Max Feed Size (mm) | Drive Motor Power (kW) | Dewatering Screen Power (kW) | Capacity (mtph) |

|---|---|---|---|---|---|

| SWD600 | 3.6 | -5 | 3.75 | 2 X 1.5 | 50 |

| SWD800 | 3.6 | -5 | 5.5 | 2 X 2.2 | 75 |

| SWD1000 | 3.6 | -5 | 5.5 | 2 X 3.7 | 100 |

| SWD1500 | 3.2 | -5 | 7.5 | 2 X 3.7 | 150 |

| SWD2000 | 3.2 | -5 | 10 | 2 X 5.5 | 200 |

| SWD2500 | 3.2 | -5 | 15 | 2 X 5.5 | 250 |

| Model No. | Rotor Speed (rpm) | Max Feed Size (in) | Drive Motor Power (HP) | Dewatering Screen Power (hp) | Capacity (stph) |

|---|---|---|---|---|---|

| SWD600 | 3.6 | -1/4 | 5 | 2 X 2 | 55 |

| SWD800 | 3.6 | -1/4 | 7.5 | 2 X 3 | 82 |

| SWD1000 | 3.6 | -1/4 | 7.5 | 2 X 5 | 110 |

| SWD1500 | 3.2 | -1/4 | 10 | 2 X 5 | 165 |

| SWD2000 | 3.2 | -1/4 | 15 | 2 X 7.5 | 220 |

| SWD2500 | 3.2 | -1/4 | 20 | 2 X 7.5 | 276 |

Product Gallery

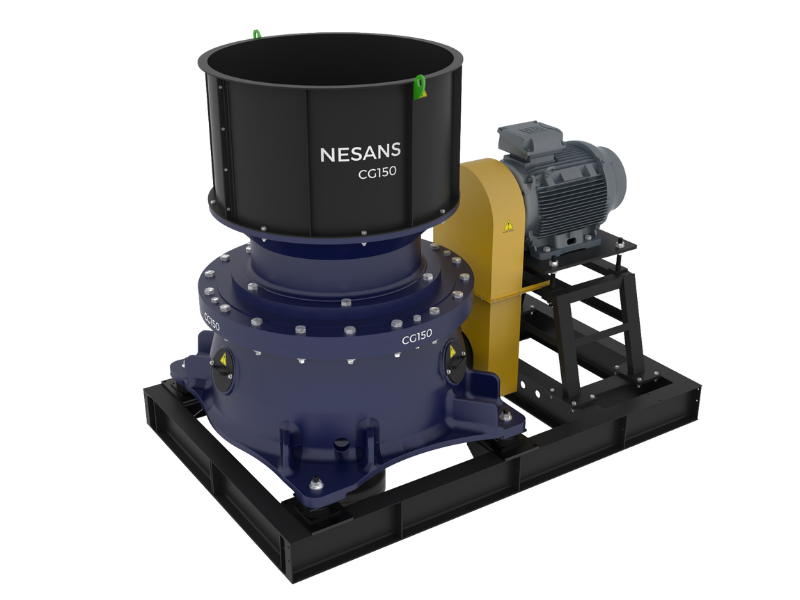

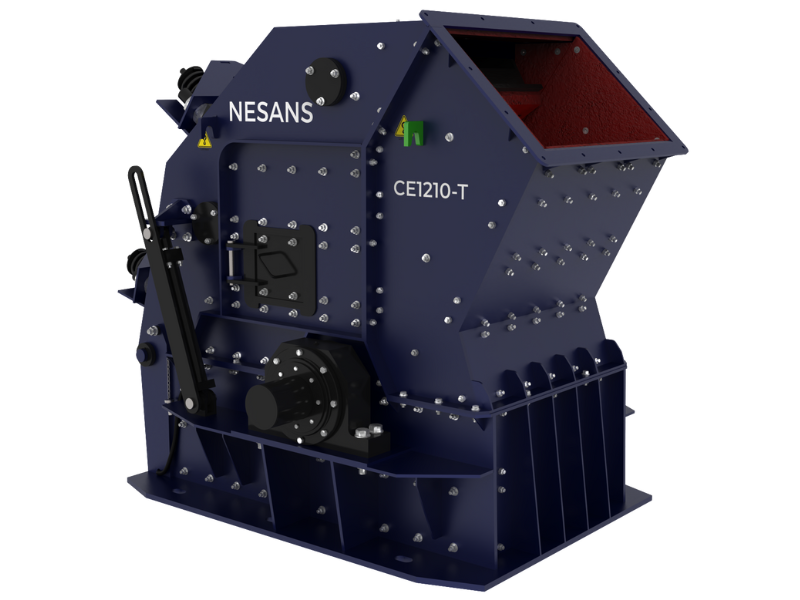

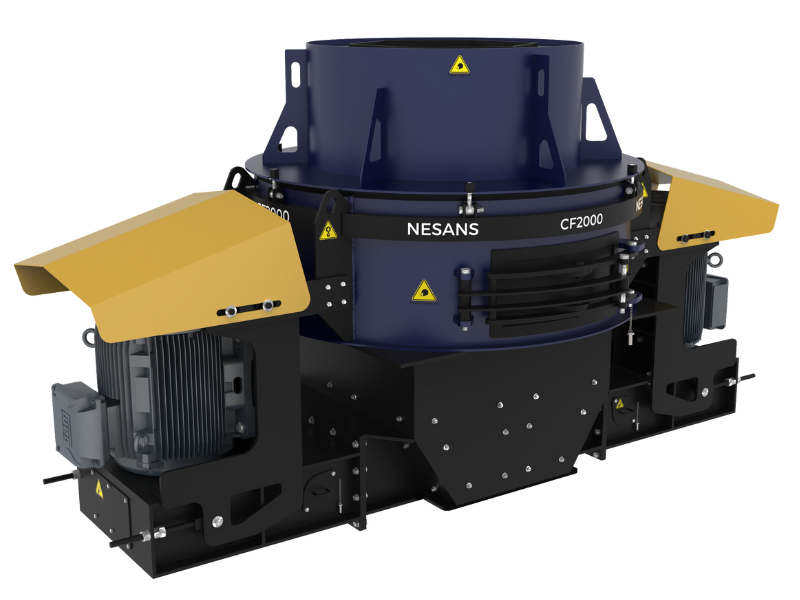

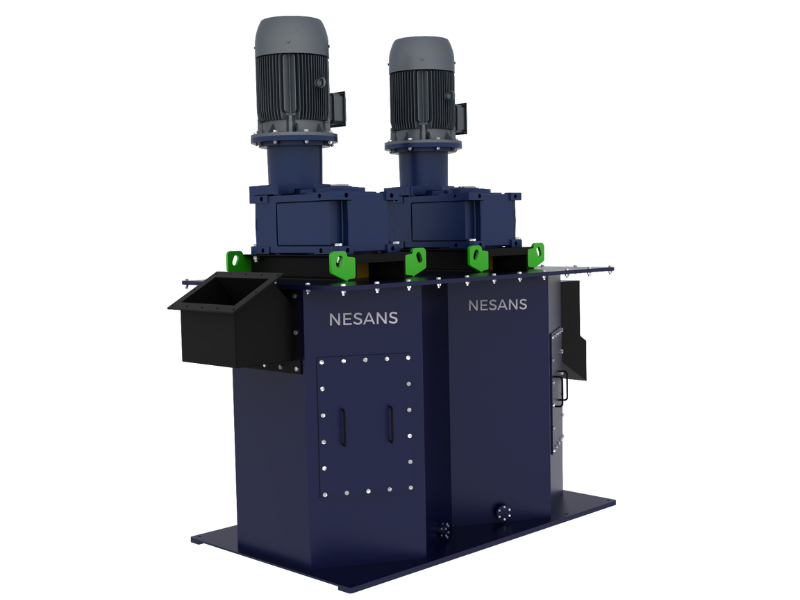

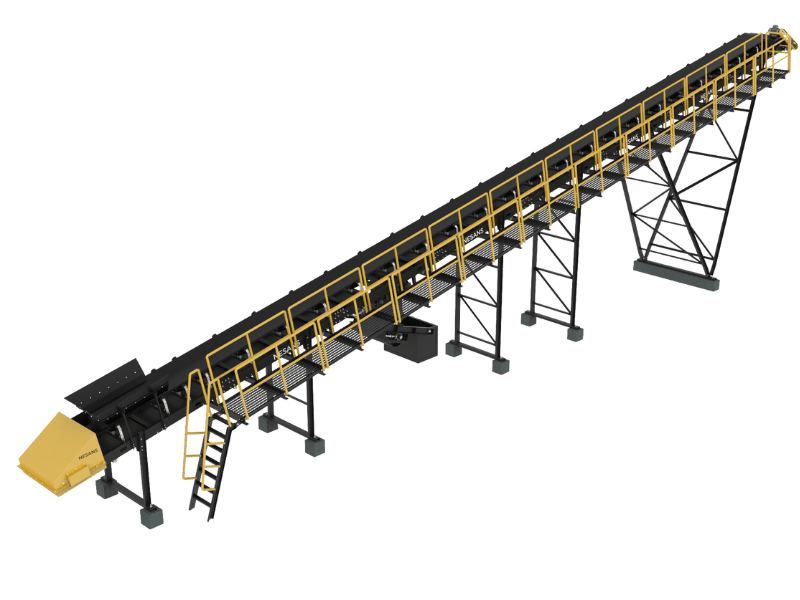

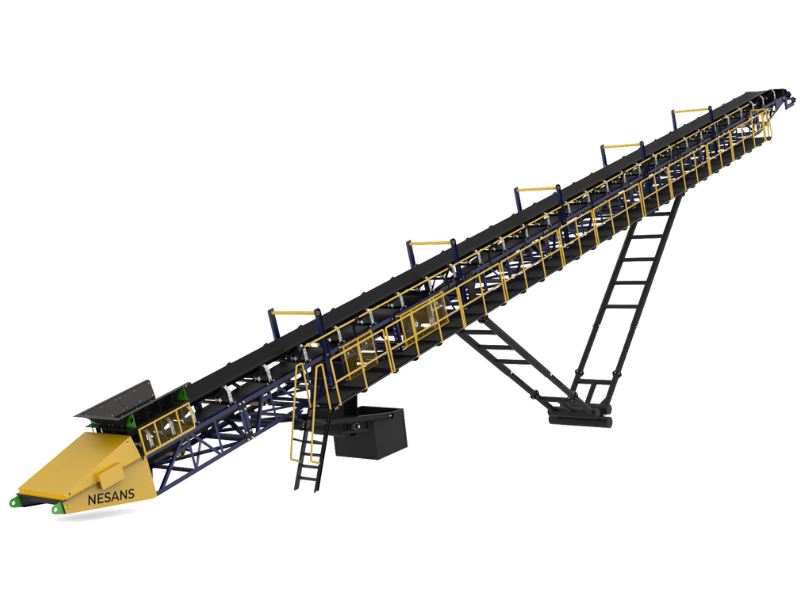

Relevant Products

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.