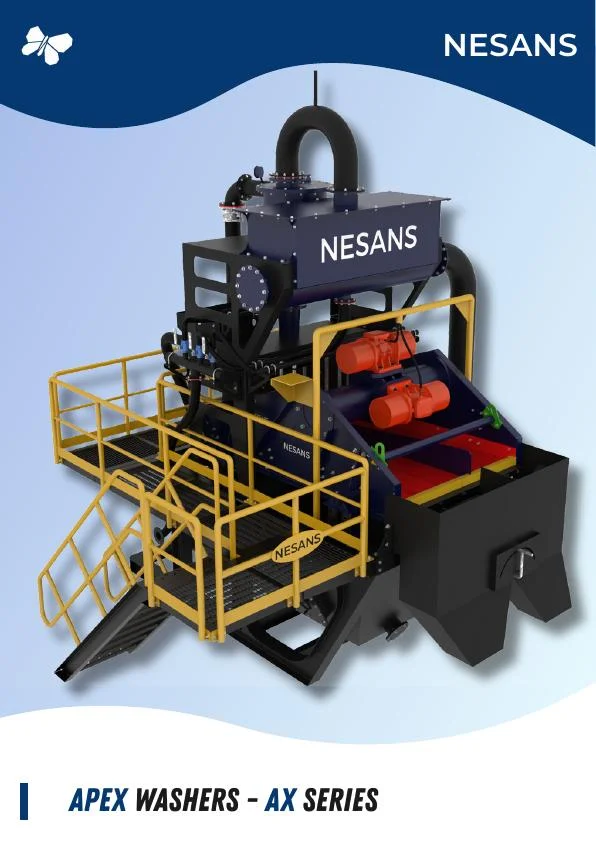

Apex Washers - AX Series

The Nesans AX Series Apex Washers are advanced hydrocyclone-based washing systems designed for high-efficiency classification, dewatering, and fines recovery. Positioned as the pro version of traditional washing systems, the AX Series integrates multiple high-performance cyclones with intelligent process control features that allow precise adjustment of cut points, slurry flow, and underflow behavior.

Engineered for versatility, the AX Series excels in a wide range of applications, including manufactured sand, silica sand washing, foundry sand preparation, and construction & demolition waste recycling. The system is built to adapt to varying feed conditions while ensuring maximum recovery of quality material and reduction in loss of fines.

With its compact footprint, reduced water demand, and advanced automation options, the AX Series stands out as a future-ready solution. Whether you’re producing spec-grade silica, reclaiming valuable foundry sand, or processing waste streams for reuse, the AX Series delivers unmatched performance, consistency, and control.

Applications:

How It Works

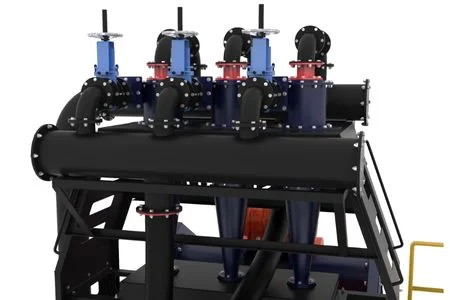

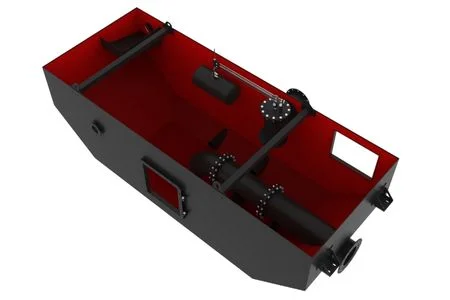

The Nesans AX Series Apex Washers operate on the principle of centrifugal classification using a cluster of high-efficiency hydrocyclones. Slurry containing sand and fine particles is pumped into the hydrocyclone module at high pressure. Inside each cyclone, the centrifugal force separates the material based on size and density—heavier particles like usable sand move downward as underflow, while lighter fines and silt exit through the overflow.

What makes the AX Series unique is its precision control over key process parameters. Operators can fine-tune variables such as feed pressure, apex size, and cyclone angle to optimize separation efficiency based on the material type. Whether it’s removing ultra-fines from silica sand, classifying foundry sand, or processing recycled waste, the system allows for targeted performance adjustments to meet exacting specifications.

Additionally, integrated dewatering mechanisms ensure that the recovered sand exits with minimal moisture, ready for further handling or stockpiling. With multiple cyclones working in parallel and built-in monitoring systems, the AX Series guarantees high throughput, reduced material loss, and consistently clean output across diverse washing applications.

Features and Advantages

Specifications

| Model No. | Flow Rate (m³/hr) | Pump Power (kW) | Max Feed Size (mm) | Dewatering Screen Power (kW) | Water Requirement (L/day) | Capacity (mtph) |

|---|---|---|---|---|---|---|

| AX1000 | 200 | 22 | -5 | 2 X 3.7 | 20000 | 90 - 110 |

| AX1500 | 260 | 37 | -5 | 2 X 5.5 | 25000 | 135-160 |

| AX2000 | 300 | 40 | -5 | 2 X 7.5 | 30000 | 180-210 |

| AX2500 | 350 | 55 | -5 | 2 X 9.3 | 35000 | 230-250 |

| Model No. | Flow Rate (gpm) | Pump Power (hp) | Max Feed Size (in) | Dewatering Screen Power (hp) | Water Requirement (gal/day) | Capacity (stph) |

|---|---|---|---|---|---|---|

| AX1000 | 880 | 30 | -1/4 | 2 X 5 | 5200 | 100 - 120 |

| AX1500 | 1144 | 50 | -1/4 | 2 X 7.5 | 7000 | 150-175 |

| AX2000 | 1320 | 60 | -1/4 | 2 X 10 | 8000 | 200-230 |

| AX2500 | 1500 | 75 | -1/4 | 2 X 12.5 | 9000 | 250-275 |

Product Gallery

Relevant Products

FAQs

It operates on the principle of centrifugal classification using a cluster of hydrocyclones and Dewatering mechanisms. Slurry containing sand and fines is pumped into the hydrocyclone module at high pressure. Inside, centrifugal force pushes heavier usable sand to the underflow, while lighter slimes and unwanted ultra-fines exit via the overflow.

It is typically placed after the final screen in the sand circuit:

Screen undersize (sand slurry) → Slurry pump → Apex Washer (cyclone cluster + dewatering screen) → Clean, classified M-Sand.

- Manufactured Sand (M-Sand) from granite, basalt, limestone.

- Silica sand processing (ultra-fines removal).

- Foundry sand classification.

- Recycled aggregates and waste fines recovery.

- Slag, fly ash, and industrial minerals.

- Hydrocyclone liners

- Apex (spigot)

- Vortex finder

- Dewatering screen media

- Pump impeller and liners

It needs process water for slurry formation, but with a thickener or filter press, up to 90% of water can be recycled.

perators can fine-tune:

- Feed pressure → controls cut size and separation sharpness.

- Apex size → adjusts fines recovery and underflow discharge.

- Cyclone angle/design → optimizes separation efficiency for different materials.

Thanks to its integrated dewatering screen, the underflow sand exits with 10–12% moisture, suitable for direct stockpiling.

The cut point is the particle size boundary where fines and usable sand are separated. In the AX Series, operators can adjust cyclone parameters to shift this cut point — ensuring consistent Zone II/III M-Sand gradation or tailoring to industrial specifications (e.g., silica sand or foundry sand).

The system includes engineered feed distribution and pressure monitoring. Operators can balance flow across all cyclones, preventing overload or bypass, and ensuring stable classification even under varying feed conditions.

Unlike basic bucket or screw washers, the AX Series gives precise control over fines removal and produces IS 383 compliant M-Sand. Its hydrocyclone cluster, integrated dewatering, and monitoring systems ensure high efficiency, reduced material loss, and consistent product quality.

No. It is widely used in industrial minerals, silica sand processing, fly ash recovery, and slag beneficiation, apart from M-Sand.

Absolutely. Fine adjustments reduce loss of usable fines into overflow streams, improving overall recovery and profitability.

- Sand gradation shifts outside spec.

- Overflow water turns excessively cloudy.

- Underflow changes from steady spray to rope discharge.

- Check cyclone underflow spray pattern.

- Inspect dewatering screen for proper vibration.

- Monitor slurry pump pressure gauge.

Not always.

- If you want a complete washing + fines removal + dewatering solution, the Apex Washer alone is sufficient.

- If you already have a washer (Apex, Envo, or even a bucket washer) but still lose usable fines in overflow, then the Superfine Classifier is added as a secondary fines recovery unit.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.