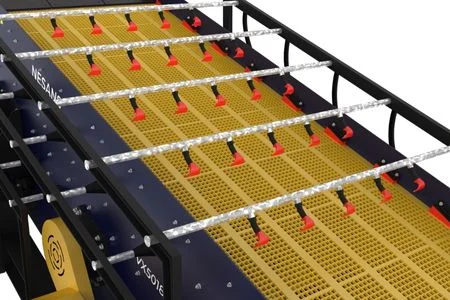

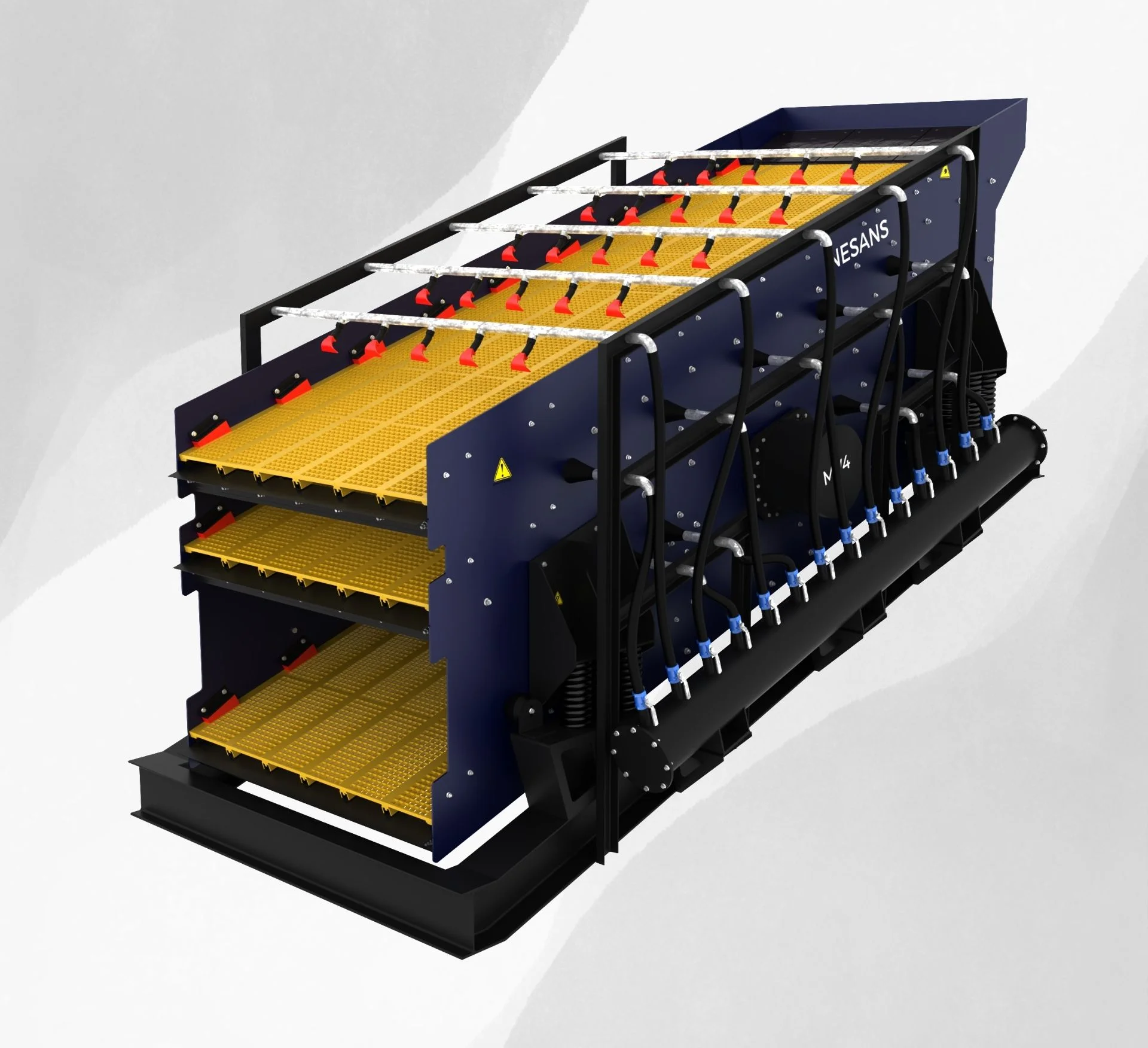

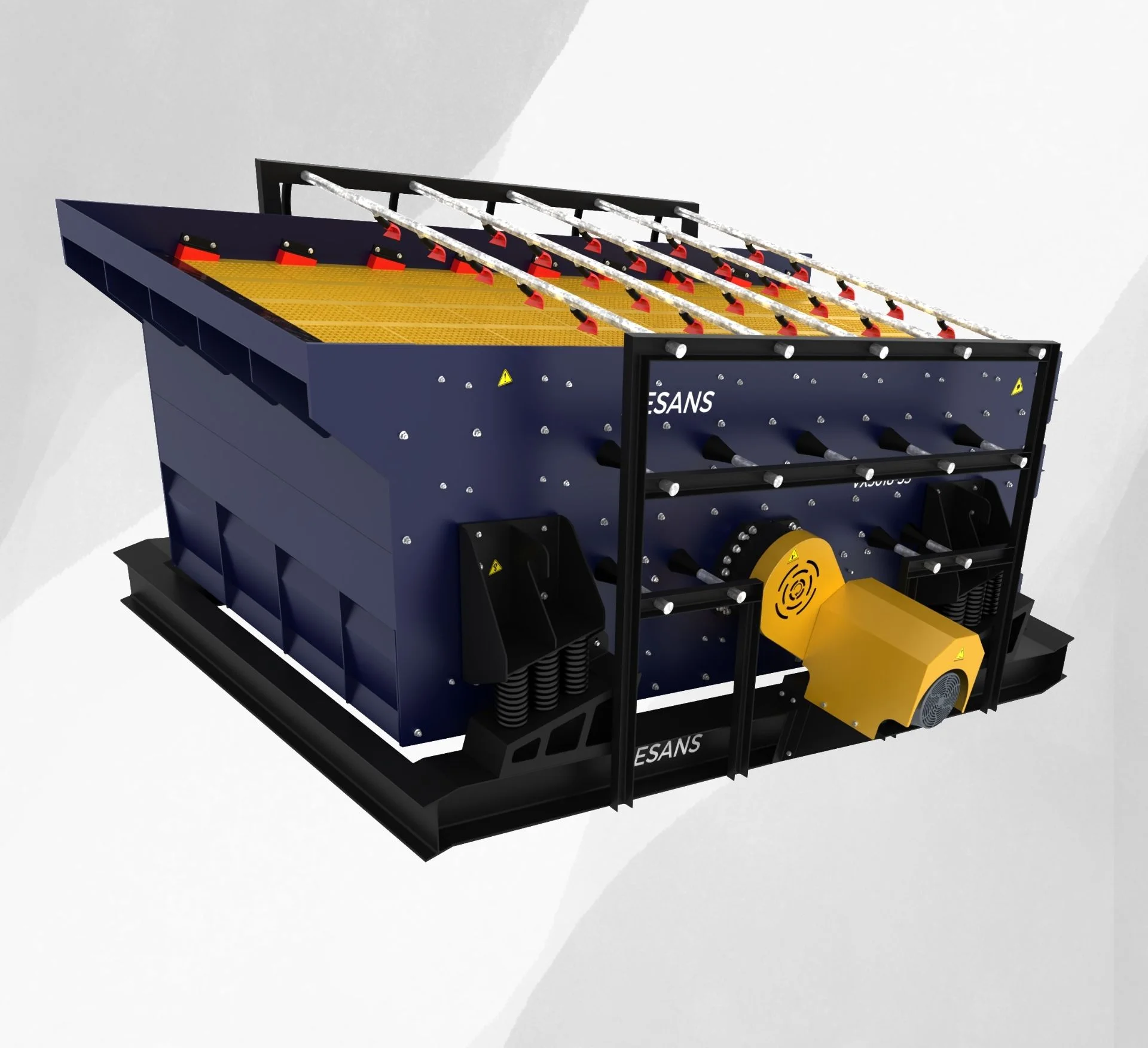

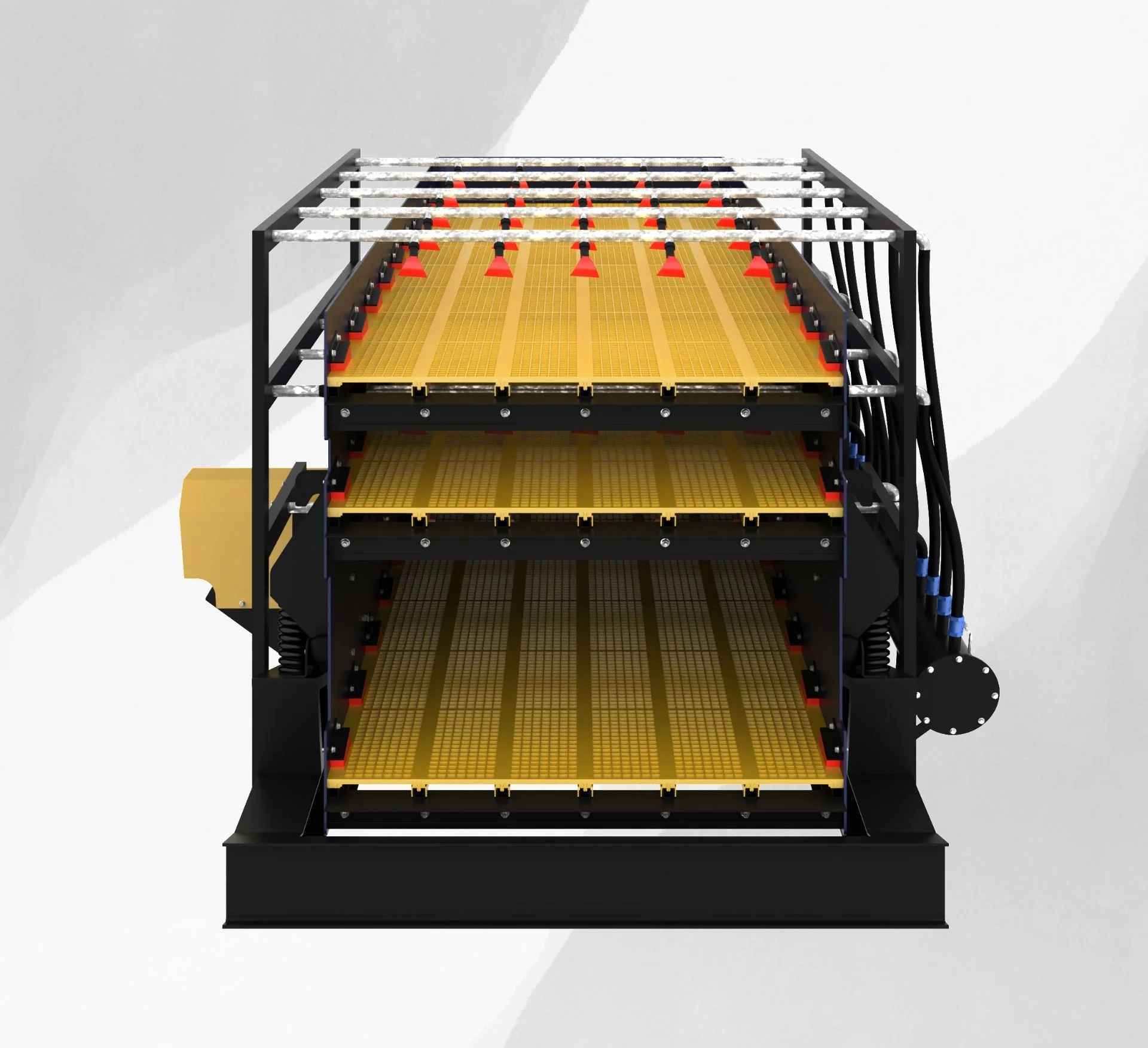

Modular Vibrating Screen - VX Series

The Nesans VX Series Modular Vibrating Screens are engineered to deliver high-efficiency screening for both dry and wet applications, making them a versatile choice for a wide range of material separation needs. Built on a modular platform, these screens combine durability with flexibility, allowing for easy configuration and maintenance based on plant requirements.

Designed with precision screening in mind, the VX Series features high-frequency vibration and optimized deck arrangements to ensure accurate stratification and maximum throughput. Whether it’s dewatering, wet classification, or dry grading, the VX Series adapts effortlessly to varying moisture levels and material characteristics, providing consistent and reliable performance.

Its modular build enables quick panel replacement and reduced downtime, while heavy-duty construction ensures long operational life even under demanding conditions. Whether used in aggregates, mining, or industrial minerals, the Nesans VX Series stands out as a dependable and efficient screening solution.

Applications:

How It Works

The Nesans VX Series operates using a modular drive mechanism that ensures smooth and efficient screening. At the core of its design is a modular bearing housing, where each module contains a pair of heavy-duty bearings. These housings are mounted on either side of the screen and are interconnected by a robust cardan shaft, which synchronizes the motion and distributes dynamic forces evenly across the machine.

As the motor drives the shaft, the eccentric weights in the bearing housings generate a consistent linear or elliptical vibration pattern, depending on the configuration. This motion causes the material to move across the screen surface, stratifying and separating it into defined fractions. The combination of modular construction and dual-bearing stability results in reduced vibration stress on the structure, efficient material flow, and the flexibility to handle both wet and dry screening applications with precision.

Features and Advantages

Specifications

| Model No. | Screen Size (mm) | Number Of Decks (Nos) | Type (Stage) | Screen Area/Deck (Sq.meter) | Approx Weight (Kg) | Motor Power (Kw) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| VX4015-4S | 4200 X 1500 | 4 | Secondary / Tertiary | 6 | 5100 | 15 | 200 |

| VX4015-3S | 4200 X 1500 | 3 | Secondary / Tertiary | 6 | 4300 | 15 | 200 |

| VX4015-2S | 4200 X 1500 | 2 | Secondary / Tertiary | 6 | 3500 | 15 | 200 |

| VX4015-3SP | 4200 X 1500 | 3 | Primary | 6 | 4300 | 15 | 200 |

| VX4015-2SP | 4200 X 1500 | 2 | Primary | 6 | 3500 | 15 | 200 |

| VX4518-4S | 4500 X 1800 | 4 | Secondary / Tertiary | 8 | 5400 | 22 | 300 |

| VX4518-3S | 4500 X 1800 | 3 | Secondary / Tertiary | 8 | 4800 | 15 | 300 |

| VX45182S | 4500 X 1800 | 2 | Secondary / Tertiary | 8 | 4000 | 15 | 300 |

| VX4518-3SP | 4500 X 1800 | 3 | Primary | 8 | 4800 | 22 | 300 |

| VX4518-2SP | 4500 X 1800 | 2 | Primary | 8 | 4000 | 15 | 300 |

| VX5020-4S | 5000 X 2000 | 4 | Secondary / Tertiary | 9 | 5600 | 22 | 350 |

| VX5020-3S | 5000 X 2000 | 3 | Secondary / Tertiary | 9 | 5000 | 22 | 350 |

| VX5020-2S | 5000 X 2000 | 2 | Secondary / Tertiary | 9 | 4200 | 15 | 350 |

| VX5020-3SP | 5000 X 2000 | 3 | Primary | 9 | 5000 | 22 | 350 |

| VX5020-2SP | 5000 X 2000 | 2 | Primary | 9 | 4200 | 22 | 350 |

| VX6020-4S | 6000 X 2000 | 4 | Secondary / Tertiary | 11 | 8700 | 30 | 500 |

| VX6020-3S | 6000 X 2000 | 3 | Secondary / Tertiary | 11 | 7500 | 30 | 500 |

| VX6020-2S | 6000 X 2000 | 2 | Secondary / Tertiary | 11 | 6600 | 22 | 500 |

| VX6020-3SP | 6000 X 2000 | 3 | Primary | 11 | 7500 | 22 | 500 |

| VX6020-2SP | 6000 X 2000 | 2 | Primary | 11 | 6600 | 22 | 500 |

| VX6024-4S | 6000 x 2400 | 4 | Secondary | 12 | 10500 | 30 | 550 |

| Model No. | Screen Size (ft) | Number Of Decks (Nos) | Type (Stage) | Screen Area/Deck (Sq.ft) | Approx Weight (lbs) | Motor Power (Hp) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| VX4015-4S | 14 X 5 | 4 | Secondary / Tertiary | 65 | 11243 | 20 | 220 |

| VX4015-3S | 14 X 5 | 3 | Secondary / Tertiary | 65 | 9479 | 20 | 220 |

| VX4015-2S | 14 X 5 | 2 | Secondary / Tertiary | 65 | 7716 | 20 | 220 |

| VX4015-3SP | 16 X 5 | 3 | Primary | 65 | 9479 | 20 | 220 |

| VX4015-2SP | 14 X 5 | 2 | Primary | 65 | 7716 | 20 | 220 |

| VX4518-4S | 15 X 6 | 4 | Secondary / Tertiary | 90 | 11904 | 30 | 330 |

| VX4518-3S | 15 X 6 | 3 | Secondary / Tertiary | 90 | 10582 | 20 | 330 |

| VX45182S | 15 X 6 | 2 | Secondary / Tertiary | 90 | 8818 | 20 | 330 |

| VX4518-3SP | 15 X 6 | 3 | Primary | 90 | 10582 | 30 | 330 |

| VX4518-2SP | 15 X 6 | 2 | Primary | 90 | 8818 | 20 | 330 |

| VX5020-4S | 16 X 6 | 4 | Secondary / Tertiary | 96 | 12345 | 30 | 385 |

| VX5020-3S | 16 X 6 | 3 | Secondary / Tertiary | 96 | 11023 | 30 | 385 |

| VX5020-2S | 16 X 6 | 2 | Secondary / Tertiary | 96 | 9259 | 20 | 385 |

| VX5020-3SP | 16 X 6 | 3 | Primary | 96 | 11023 | 30 | 385 |

| VX5020-2SP | 16 X 6 | 2 | Primary | 96 | 9259 | 30 | 385 |

| VX6020-4S | 20 X 6 | 4 | Secondary / Tertiary | 120 | 19180 | 40 | 551 |

| VX6020-3S | 20 X 6 | 3 | Secondary / Tertiary | 120 | 16534 | 40 | 551 |

| VX6020-2S | 20 X 6 | 2 | Secondary / Tertiary | 120 | 14550 | 30 | 551 |

| VX6020-3SP | 20 X 6 | 3 | Primary | 120 | 16530 | 30 | 551 |

| VX6020-2SP | 20 X 6 | 2 | Primary | 120 | 14550 | 30 | 551 |

| VX6024-4S | 20 x 7 | 4 | Secondary | 130 | 23148 | 40 | 606 |

Product Gallery

FAQs

It uses a modular drive mechanism with heavy-duty bearing housings on either side of the screen, synchronized by a robust cardan shaft. As the motor drives the shaft, eccentric weights generate linear or elliptical vibration (depending on configuration). This motion stratifies and separates the material into defined fractions.

Sand, gravel, crushed stone, industrial minerals, ores, coal, and other fine-to-coarse bulk solids.

- Screen media (modular PU, rubber, or wire panels).

- Bearings in the modular housings.

- Cardan shaft and couplings.

Yes. It is designed for wet classification, dewatering, and dry grading, making it suitable for varying moisture levels and feed conditions.

The high-frequency vibration and optimized deck arrangements allow for better stratification, higher throughput, and accurate separation of fine and coarse fractions.

It can be placed:

- After a crusher → to size and separate material.

- Before washing → to remove fines or classify feed.

- After washing/classification → for final grading or dewatering.

Yes. The synchronized cardan shaft and balanced dual-bearing modules distribute forces evenly, reducing vibration transfer to the base structure.

Yes. It can be tuned with different deck angles, stroke settings, and screen media to suit your feed material

Yes. The synchronized vibration system keeps motion consistent even under variable load conditions, ensuring reliable separation and preventing material carryover.

No. The dual-bearing system and heavy-duty coil springs isolate vibration, reducing both noise and structural stress on the foundation.

Signs include:

- Overflow of fines in the oversize fraction.

- Unusual noise from bearings or shaft.

- Uneven material distribution across the deck.

Routine monitoring of vibration and throughput helps detect issues early.

- Aggregates – sizing and grading crushed stone and sand.

- Mining & Minerals – wet classification, dewatering, and ore separation.

- Industrial minerals – silica, feldspar, coal, and fertilizers.

- Daily: Monitor for abnormal noise or heat.

- Weekly: Check lubrication levels and housing seals.

- Monthly: Inspect cardan shaft couplings and alignment.

- Horizontal screen: Great for precision, but lower capacity.

- Inclined screen: High-speed, multi-slope, best for ultra-high throughput.

- Modular Screen: Balanced between capacity, accuracy, and flexibility, with easier service and adaptability.

Yes. Modular parts and quick panel changes make servicing much faster than traditional designs.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.