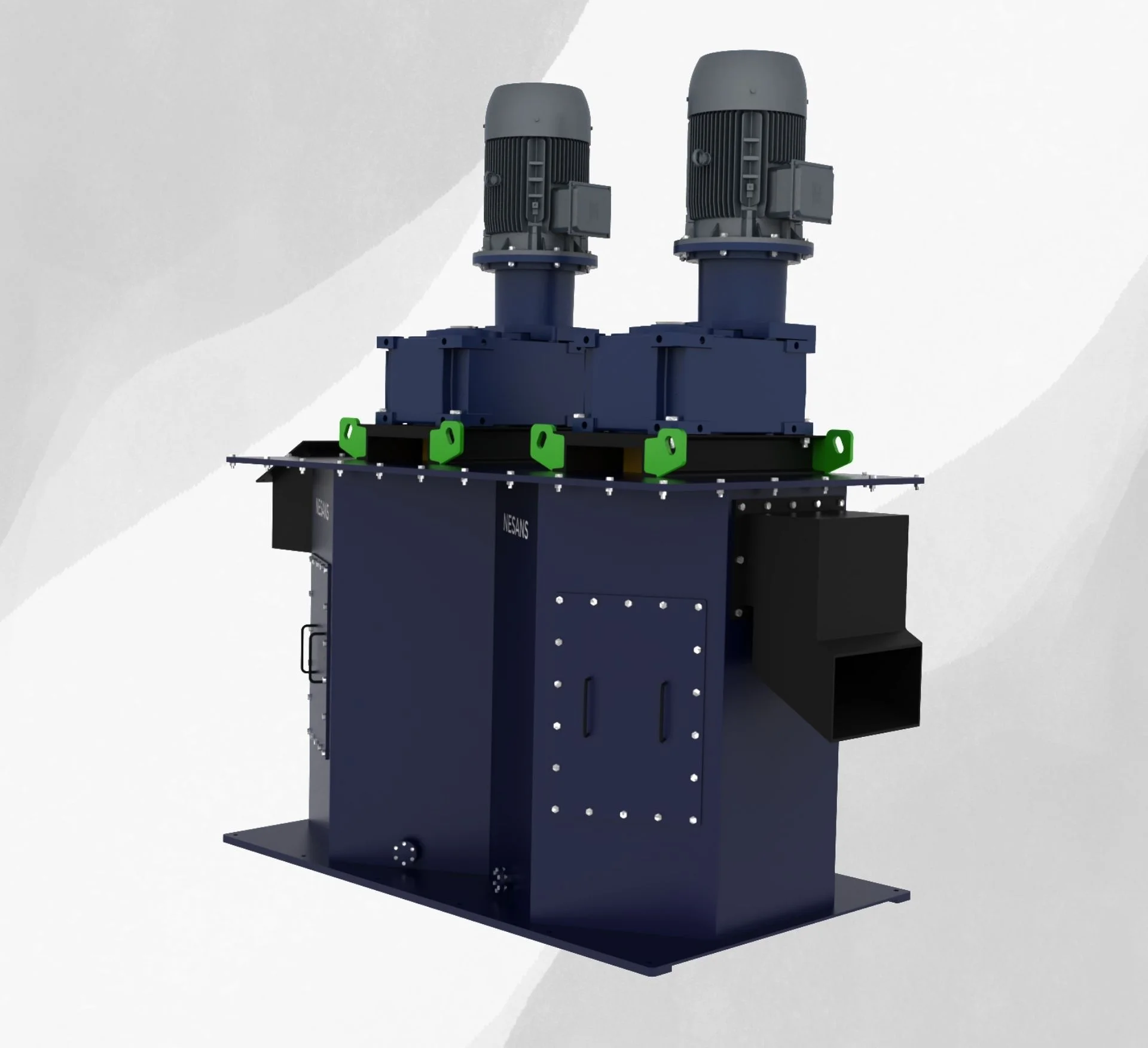

Attrition Scrubber - R Series

The Nesans R Series Attrition Scrubbers are designed for intensive scrubbing and surface cleaning of mineral particles, targeting the removal of tough contaminants like clay, coatings, and soft silica layers that conventional washing systems cannot eliminate. This makes the R Series an essential unit in processes such as silica sand purification, foundry sand conditioning, and mineral beneficiation where surface cleanliness is critical.

Each scrubber consists of contra-rotating paddle shafts that generate aggressive inter-particle friction and high-energy turbulence within the tank. This action breaks down bonded impurities and liberates fines without degrading the particle structure. The result is a cleaner, more refined product, perfectly suited for applications that require precise surface quality and material integrity.

To suit different capacity and process requirements, multiple scrubber cells can be connected in series, enabling longer retention times and deeper scrubbing intensity. With a focus on durability, low maintenance, and efficient performance, the Nesans R Series offers a rugged and flexible solution for advanced mineral cleaning and upgrading.

Applications:

How It Works

The Nesans R Series Attrition Scrubber operates on the principle of mechanical agitation and inter-particle scrubbing to remove surface contaminants and loosely bonded impurities. Feed slurry is introduced into the scrubber tank, where a set of contra-rotating paddle shafts vigorously mix the particles. This high-energy motion causes intense collisions between particles, effectively scrubbing off clay, coatings, and other unwanted materials from the grain surfaces.

The turbulence created inside the tank ensures uniform energy distribution, promoting efficient surface cleaning without fracturing the particles. The scrubbed slurry then flows out to the next stage of processing—typically classification, washing, or dewatering—depending on the plant setup.

For applications requiring more aggressive treatment or longer retention, multiple scrubber cells can be connected in series, allowing for staged scrubbing and increased material contact time. This modularity ensures flexibility in process design and enhances the overall cleaning efficiency, making the R Series a powerful solution for material upgrading in demanding mineral applications.

Features and Advantages

Specifications

| Model No. | Impeller Diameter (mm) | Cell Volume (m³) | Pulp Density Solids (%) | Impeller Speed (rpm) | Motor Power (Kw) | Scrubbing Time (min/cell) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| R2 | 1016 | 1.7 | 70% - 80% | 900 | 55 | 1.2 - 1.6 | 80 - 120 |

| R3 | 1625 | 3.4 | 70% - 80% | 1800 | 55 - 110 | 1 - 1.4 | 180 - 220 |

| R6 | 1295 | 5.7 | 65% - 70% | 900 - 1800 | 55 - 110 | 1.4 - 1.7 | 200 - 220 |

| Model No. | Impeller Diameter (in) | Cell Volume (ft³) | Pulp Density Solids (%) | Impeller Speed (rpm) | Motor Power (Hp) | Scrubbing Time (min/cell) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| R2 | 40 | 60 | 70% - 80% | 900 | 75 | 1.2 - 1.6 | 88 - 132 |

| R3 | 64 | 120 | 70% - 80% | 1800 | 75 - 150 | 1 - 1.4 | 198 - 243 |

| R6 | 52 | 200 | 65% - 70% | 900 - 1800 | 75 - 150 | 1.4 - 1.7 | 220 - 243 |

Product Gallery

Relevant Products

FAQs

It uses mechanical agitation and inter-particle scrubbing. Feed slurry enters a tank fitted with contra-rotating paddle shafts that create intense turbulence. This motion causes sand grains or mineral particles to collide with each other, scrubbing off clays, coatings, and surface contaminants.

Typically: Washer/classifier → R Series Attrition Scrubber → Hydrocyclone/Classifier → Dewatering → Product stockpile.

- Silica sand (to remove iron-stained coatings and clays).

- Manufactured sand (to remove excess slimes).

- Industrial minerals (kaolin, feldspar, phosphate, bauxite).

- Recycled aggregates and waste fines.

The contra-rotation ensures a high-energy, turbulent environment with uniform energy distribution across the tank. This delivers efficient cleaning while preventing particle buildup inside the chamber.

No. The design creates enough energy to remove surface impurities but not enough to fracture the grains, preserving particle size and shape.

The scrubbed slurry is discharged to the next processing stage — usually classification or washing — to separate the liberated fines from the clean sand/minerals.

Yes—scrubbing actually helps when clays rise. Keep solids density and residence time in range, then let the classifier do the fines removal.

Typical retention time is 5–15 minutes, depending on the degree of contamination.

No. Once slurry feed and retention time are set, the scrubber operates automatically. Operators mainly monitor motor load and slurry consistency.

It removes stubborn surface coatings, clay lumps, and loosely bonded impurities that normal washing or cycloning cannot handle. This improves sand quality, brightness (for silica), and compliance with construction standards.

- Normal washer: Removes only loose dirt and silt with water.

- R Series Attrition Scrubber: Removes firmly adhered clays, coatings, and stains by inter-particle scrubbing.

Yes. The scrubber cleans the surfaces but does not separate fines. Classification or washing is required afterward to remove the liberated impurities.

No. It is also effective for construction M-Sand, mineral beneficiation, and recycled aggregate cleaning, wherever surface coatings reduce product quality.

- Attrition scrubber: sand-size feed, coating removal, minimal breakage, compact footprint.

- Log washer: coarser, lumpy feeds with heavy mudballs; more aggressive, larger footprint.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.