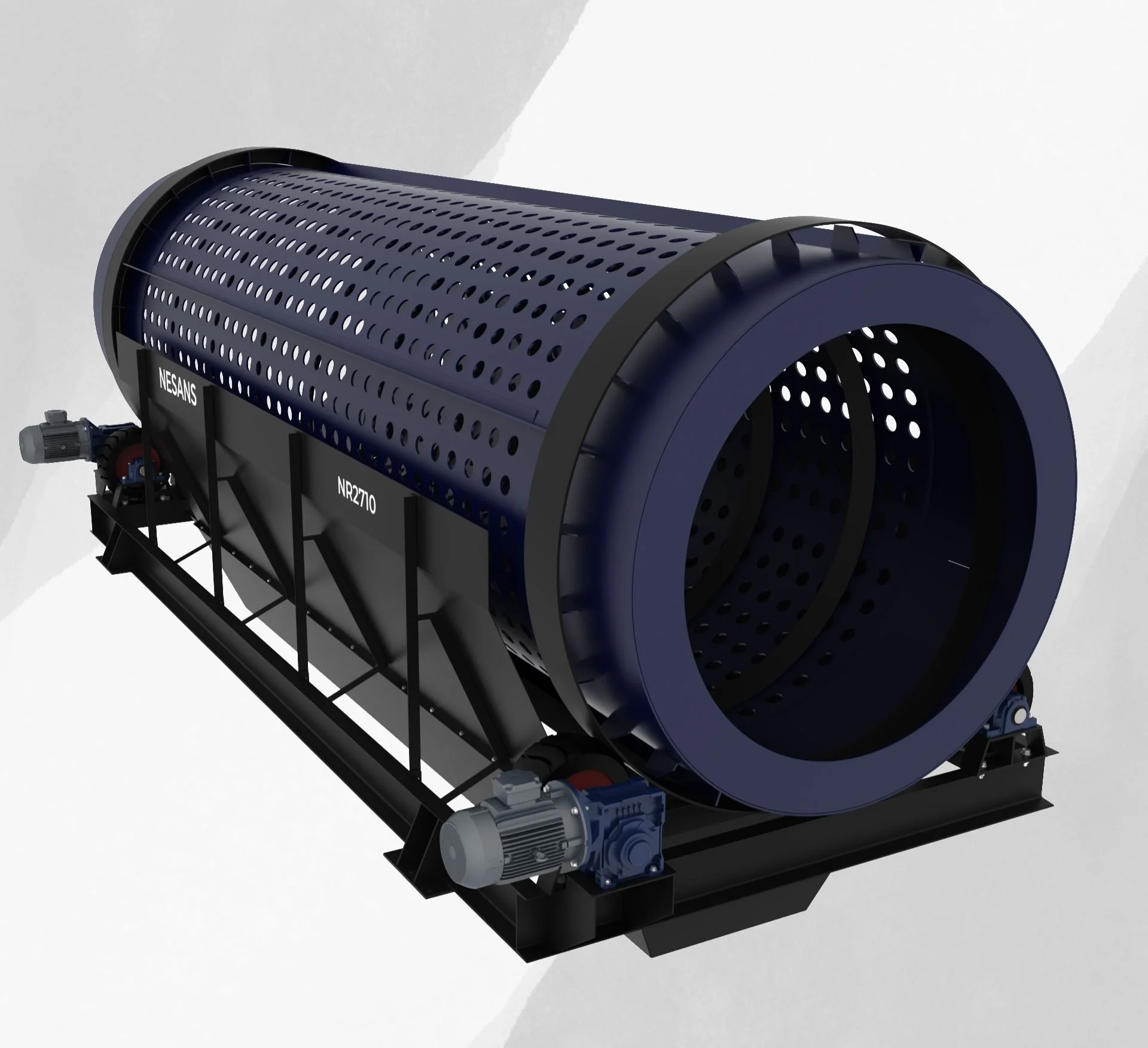

Trommel Screen - NR Series

The Nesans NR Series Trommel Screens are purpose-built for solid waste recycling and material recovery applications, offering a highly effective solution for separating materials based on size. With their robust design and rotating drum mechanism, the NR Series excels in handling municipal solid waste (MSW), construction & demolition waste, compost, plastic scraps, biomass, and other recyclable streams. The gentle tumbling motion and open-screen design reduce clogging and ensure efficient throughput, even with wet or sticky materials.

Designed for continuous-duty performance, the NR Series features a perforated rotating drum that progressively separates materials as it turns. Fine particles fall through the screening holes while larger or non-recyclable materials are conveyed to the discharge end. This screening process not only improves sorting efficiency but also plays a critical role in reducing landfill volumes and maximizing recovery of valuable materials.

With options for different mesh sizes, modular screening zones, and heavy-duty build quality, the NR Series is highly adaptable to diverse recycling environments. Whether you’re operating a transfer station, composting facility, or materials recovery facility (MRF), the Nesans NR Series Trommel Screen offers unmatched reliability, low maintenance, and operational flexibility—making it an essential tool in any sustainable waste management or recycling operation.

Applications:

How It Works

The Nesans NR Series Trommel Screens operate using a rotating cylindrical drum fitted with perforated openings sized according to the desired material separation. Material—such as municipal solid waste, construction debris, compost, or recyclable fractions—is fed into the elevated end of the drum. As the drum slowly rotates, internal lifters gently tumble and advance the material forward along its length.

During this motion, finer particles pass through the holes in the drum and are collected below, while oversized or non-recyclable materials continue to travel toward the discharge end for further processing or disposal. The constant rotation and tumbling action ensure effective stratification and minimize screen clogging, even with moist or sticky input materials.

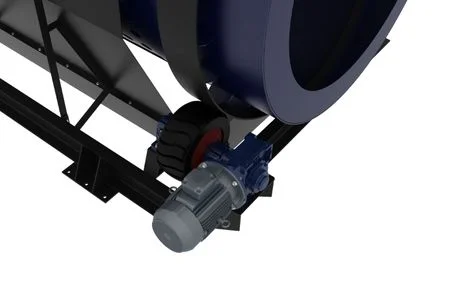

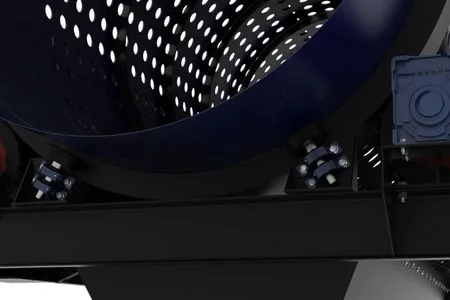

The entire system is mounted on heavy-duty trunnion wheels and powered by a robust drive system, allowing for smooth, stable, and continuous operation. Modular drum segments can be customized with varying hole sizes or screen types to achieve multi-stage separation, enabling the NR Series to handle a wide variety of waste streams with high accuracy and minimal downtime.

Features and Advantages

Specifications

| Model No. | Diameter (mm) | Screening length (mm) | Total Length (mm) | Motor Power (Kw) | Performances (m³/hr) |

|---|---|---|---|---|---|

| NR2170 | 2100 | 5000 | 7000 | 11 | 55 |

| NR2190 | 2100 | 7000 | 9000 | 15 | 85 |

| NR2508 | 2500 | 6000 | 8000 | 15 | 70 |

| NR2510 | 2500 | 8000 | 10000 | 15 | 110 |

| NR2512 | 2500 | 10000 | 12000 | 2 X 11 | 130 |

| NR2514 | 2500 | 12000 | 14000 | 2 X 15 | 155 |

| NR3010 | 3000 | 8000 | 10000 | 15 | 150 |

| NR3012 | 3000 | 10000 | 12000 | 2 X 11 | 175 |

| NR3014 | 3000 | 12000 | 14000 | 2 X 15 | 210 |

| Model No. | Diameter (ft) | Screening length (ft) | Total Length (ft) | Motor Power (Hp) | Performances (ft³/hr) |

|---|---|---|---|---|---|

| NR2170 | 6.5 | 16 | 23 | 15 | 1942 |

| NR2190 | 6.5 | 23 | 30 | 20 | 3001 |

| NR2508 | 8 | 20 | 26 | 20 | 2472 |

| NR2510 | 8 | 26 | 32 | 20 | 3884 |

| NR2512 | 8 | 33 | 39 | 2 X 15 | 4590 |

| NR2514 | 8 | 39 | 46 | 2 X 20 | 5473 |

| NR3010 | 10 | 26 | 32 | 20 | 5297 |

| NR3012 | 10 | 33 | 39 | 2 X 15 | 6180 |

| NR3014 | 10 | 39 | 46 | 2 X 20 | 7416 |

Product Gallery

FAQs

A trommel screen is a rotating cylindrical drum with perforated openings used to separate materials based on size. As waste enters the drum, it is lifted and dropped while the drum rotates. Smaller particles fall through the holes, while larger materials move along the drum length to discharge.

Its rotating, tumbling action is ideal for handling irregular, sticky, or mixed materials like municipal waste, compost, and construction debris. Unlike flat screens, it resists clogging and ensures continuous separation.

A trommel screen is usually placed after shredding or feeding, where it separates fines from oversize material.

- In MSW plants → after shredders/bag openers, fines go to compost, oversize to sorting.

- In C&D waste → after feed hopper/crusher, fines are screened out, oversize goes to manual/automated sorting.

- In composting → at the end, to separate clean compost from oversize rejects.

Yes. The tumbling action prevents clogging, making it suitable for moist compost, wet MSW fines, and clay-rich C&D waste.

- Drum liners / perforated panels.

- Drive system (gears, chains, or motors).

- Support wheels and bearings.

Choose perforation size based on what you want as fines. For example:

- Compost fines: 10–20 mm

- MSW organics: 50–80 mm

- C&D soil/fines: 20–40 mm

Yes. Steady feed ensures consistent screening. Sudden surges reduce efficiency and may overload the drum.

Pick a trommel for sticky, high-moisture, mixed, or trashy feeds; its rotating drum and lifters keep material moving and self-cleaning. Use vibrating screens when you need tight accuracy on small cuts and a compact footprint.

Yes. By pre-separating fines and oversize, your workers or automated sorters handle less mixed material, improving efficiency and lowering labor costs.

- Check if holes are clogged.

- Inspect drum speed (slipping drive belts/chains).

- Verify feed consistency.

- Replace worn panels if open area is reduced.

Yes. By separating fines and organics for reuse, only true rejects go to landfill, lowering disposal costs significantly.

No. The gentle tumbling separates by size without crushing. Sharp impacts are avoided, making it safe for downstream recycling.

No. Trommels are designed for easy access to panels and drive components. Regular greasing of bearings and checking drum alignment keeps downtime minimal.

- Handles mixed, contaminated waste streams.

- Low operating cost and simple maintenance.

- Suitable for pre-sorting before advanced equipment like air separators or optical sorters.

- Municipal Solid Waste (MSW): Separating organics, fines, and recyclables.

- Construction & Demolition (C&D): Screening soil, aggregates, and inert fines.

- Composting: Removing oversized materials from compost.

- Metal Recovery: Pre-sorting scrap and fines before magnetic/eddy current separation.

- Plastic Recycling: Size separation of shredded plastics.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.