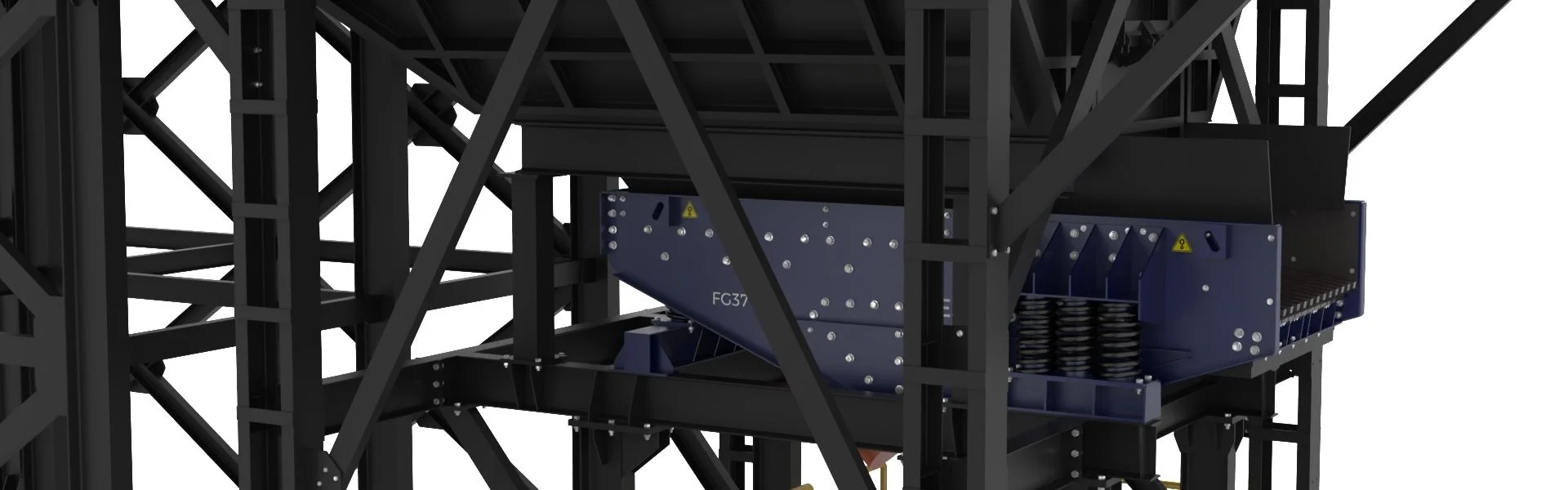

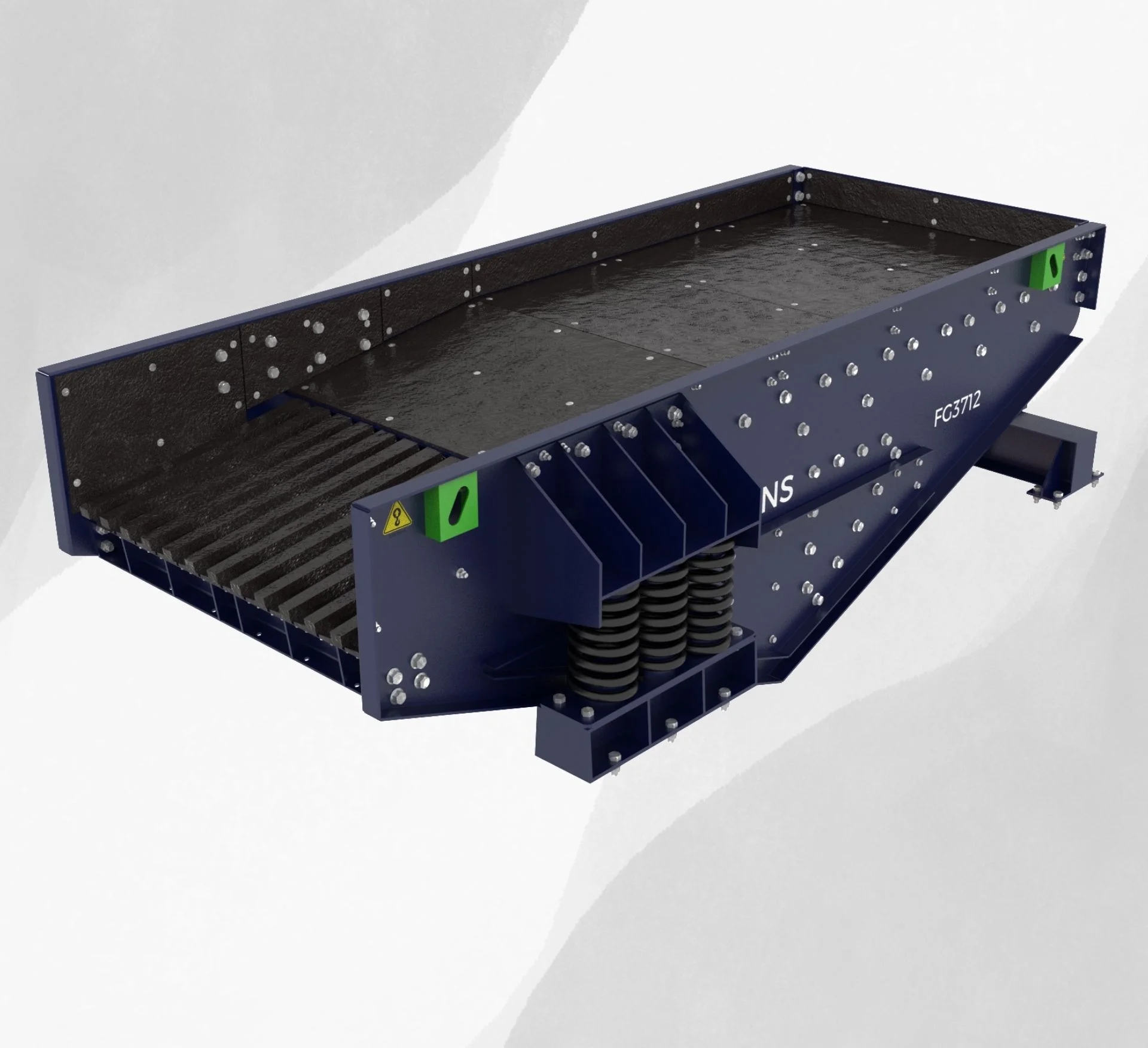

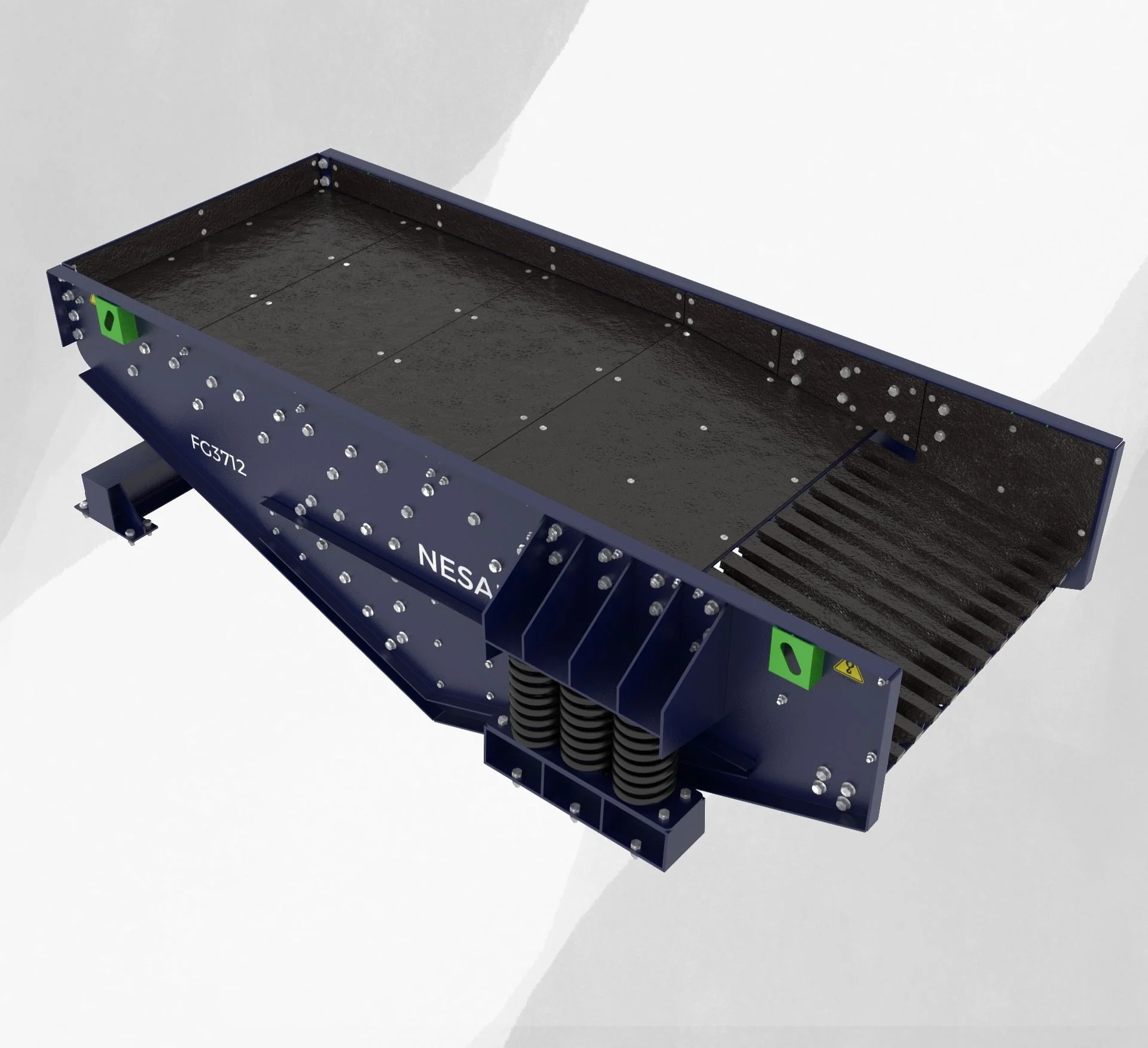

Grizzly Feeder - FG Series

The Nesans FG Series Grizzly Feeders are engineered for heavy-duty feeding and pre-screening applications in primary crushing circuits. Designed to handle high-impact loads and large feed sizes, the FG Series combines rugged construction with precise vibratory motion to ensure a consistent and regulated flow of material to crushers or secondary processing equipment.

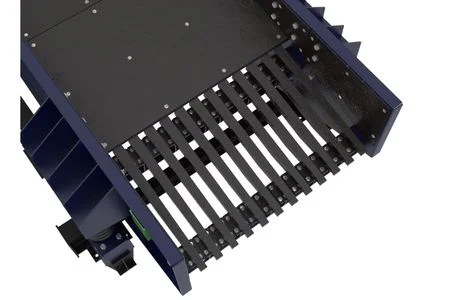

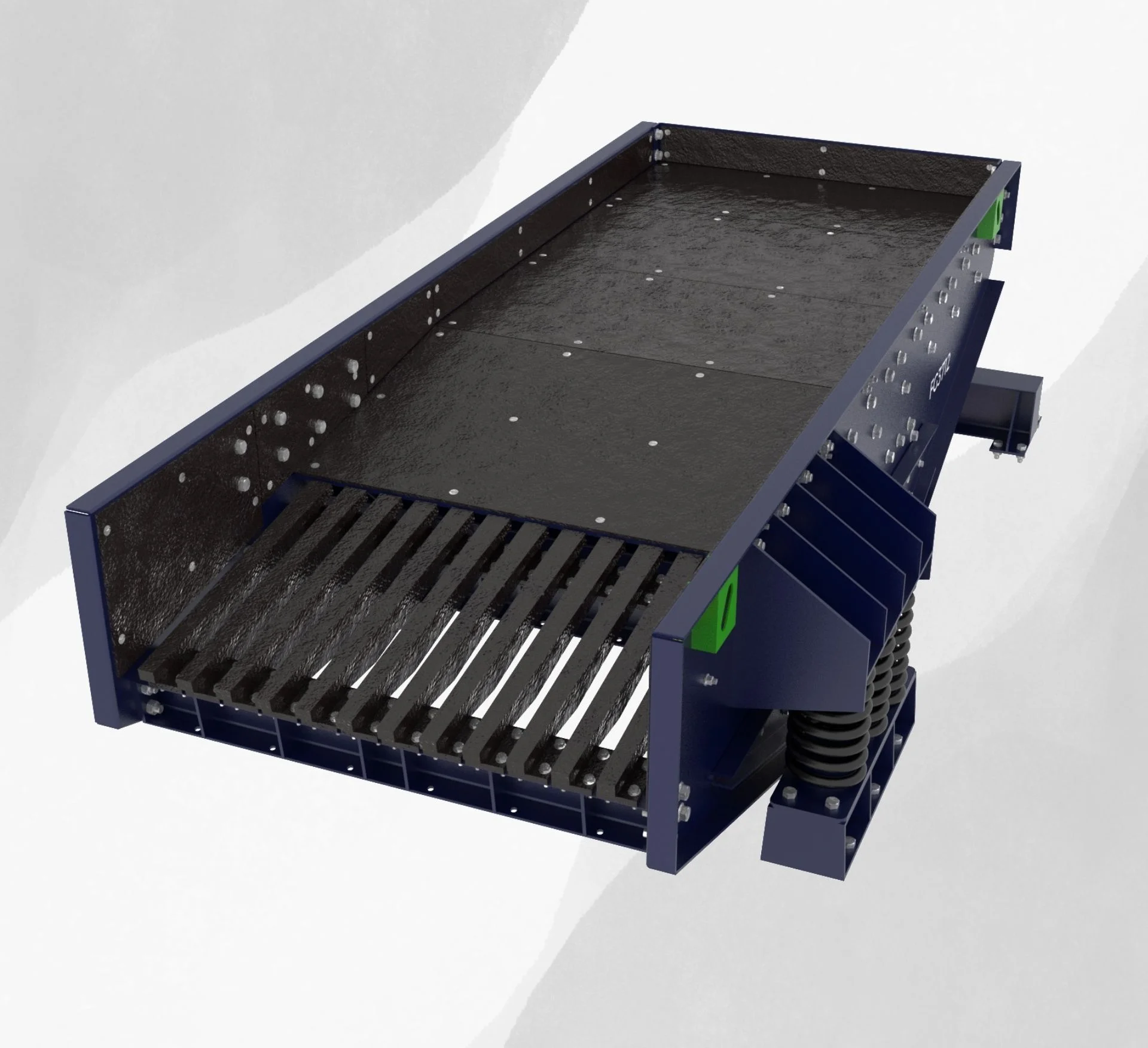

The feeder tray features a two-zone design: a solid pan section for initial material loading and impact absorption, followed by a grizzly bar section that screens out fines and bypasses smaller material before it reaches the crusher. This reduces wear on downstream equipment and improves overall plant performance and efficiency.

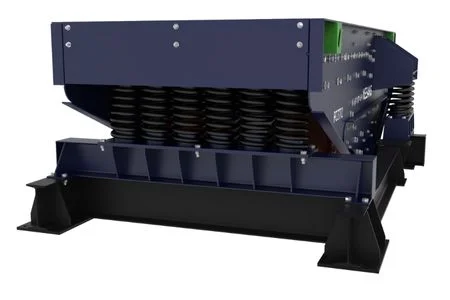

Mounted on high-compression springs and driven by twin vibro motors, the FG Series delivers powerful linear motion to move coarse material smoothly while maintaining separation efficiency. With options for replaceable liners, adjustable grizzly spacing, and chute protection, it’s a durable, low-maintenance solution tailored for demanding quarry and mining environments.

Applications:

How It Works

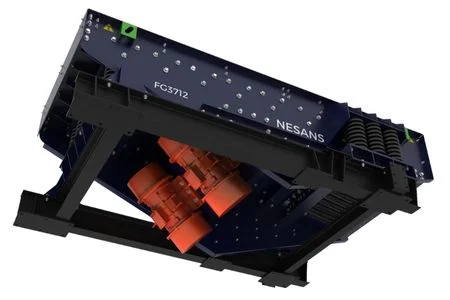

The Nesans FG Series Grizzly Feeders work by combining vibratory force and a dual-section deck design to regulate the flow of large feed material while removing fines early in the process. Material enters the feeder from a hopper or bin and is first met by a solid pan section that absorbs impact and begins moving the material forward via linear vibrations generated by twin unbalanced vibro motors.

As the material progresses along the feeder, it reaches the grizzly section, which consists of heavy-duty bars spaced to allow finer particles to fall through. These fines are discharged through the spacing between the bars, bypassing the primary crusher and reducing wear, energy consumption, and unnecessary load. The oversized material continues toward the discharge end and into the crusher or next stage of processing.

Supported by robust coil springs, the entire structure vibrates efficiently while isolating the base frame from dynamic forces. The result is controlled, efficient feeding and pre-screening, ensuring smoother operation, extended equipment life, and improved downstream performance.

Features and Advantages

Specifications

| Model No. | Max Length (mm) | Max Width (mm) | Motor Power (Kw) | Capacity (mtph) |

|---|---|---|---|---|

| FG3109 | 3100 | 900 | 2 x 2.6 | 150 |

| FG3712 | 3660 | 1200 | 2 x 3.75 | 200 |

| FG4512 | 4500 | 1200 | 2 x 5.6 | 300 |

| Model No. | Max Length (ft) | Max Width (ft) | Motor Power (Hp) | Capacity (stph) |

|---|---|---|---|---|

| FG3109 | 10 | 3 | 2 x 3.5 | 165 |

| FG3712 | 12 | 4 | 2 x 5 | 220 |

| FG4512 | 15 | 4 | 2 x 7.5 | 331 |

Product Gallery

Relevant Products

Belt Feeder

Learn More

Vibro Feeder

Learn MoreFAQs

A Grizzly Feeder is a vibrating feeder with heavy-duty grizzly bars that scalps oversize material before it reaches the primary crusher. As material is fed from the hopper, vibration moves it forward while smaller particles fall through the grizzly gaps, and larger material continues to the crusher.

Right ahead of the primary jaw. A VGF absorbs impact, meters the feed, and scalps fines (material already smaller than the jaw CSS) so only rock that needs crushing enters the chamber.

It is designed for large, heavy, and abrasive rock such as granite, basalt, and limestone, as well as mixed quarry run material.

- Grizzly bars.

- Liners in the feed zone.

- Vibratory exciter bearings.

It uses twin unbalanced vibro motors that create linear vibration, moving material steadily toward the crusher.

Removing fines before crushing:

- Increases crusher life.

- Improves crusher efficiency.

- Reduces power consumption.

Yes. The vibrating action ensures a steady, controlled feed rate, preventing surges or blockages in the crusher.

The solid impact section and reinforced side plates absorb shock loads, ensuring reliable feeding even with very large feed lumps.

- Quarry primary crushing plants (feeding jaw or impact crushers).

- Mining operations (scalping before crushers or screens).

- Sand & aggregate plants (removing fines before crushing).

Yes. By removing fines early, it extends crusher liner life, reduces maintenance downtime, and cuts overall energy consumption.

They are modular and bolt-on, allowing quick replacement without dismantling the entire feeder.

Yes. Vibration speed and amplitude can be adjusted, allowing control of both flow rate and scalping efficiency.

Both indirectly,By removing fines and stabilizing the jaw load, you get more consistent reduction and less recirculating load downstream, which improves overall plant shape and energy per ton.

- Uneven material flow → possible worn bars or motor imbalance.

- Excessive noise → loose fasteners or damaged springs.

- Reduced scalping efficiency → worn grizzly bars.

- Overheating motors → improper lubrication or overloading.

By feeding the crusher a more uniform, fines-free material, it prevents crusher overloading, reduces recirculation, and improves overall plant efficiency.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.