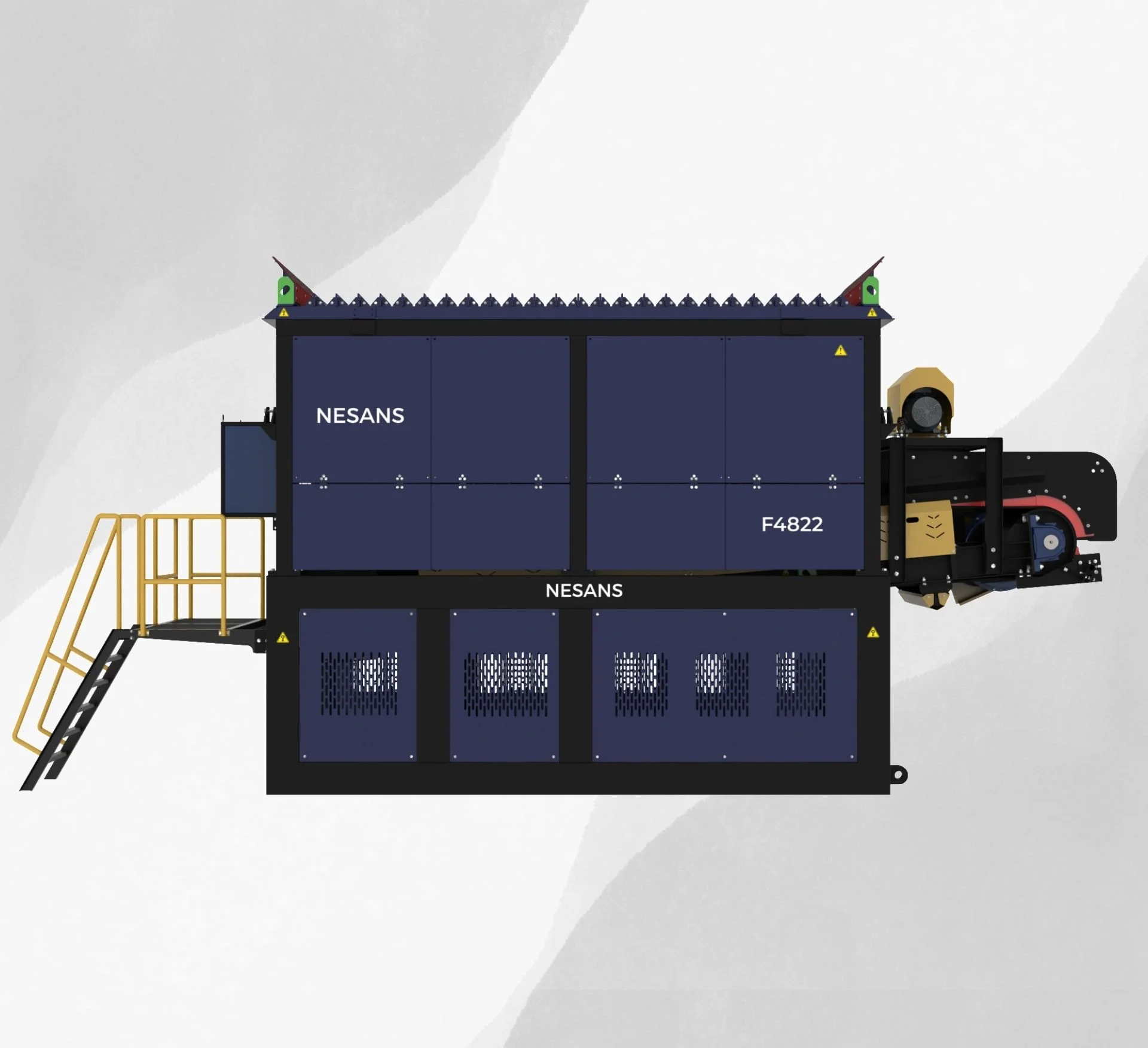

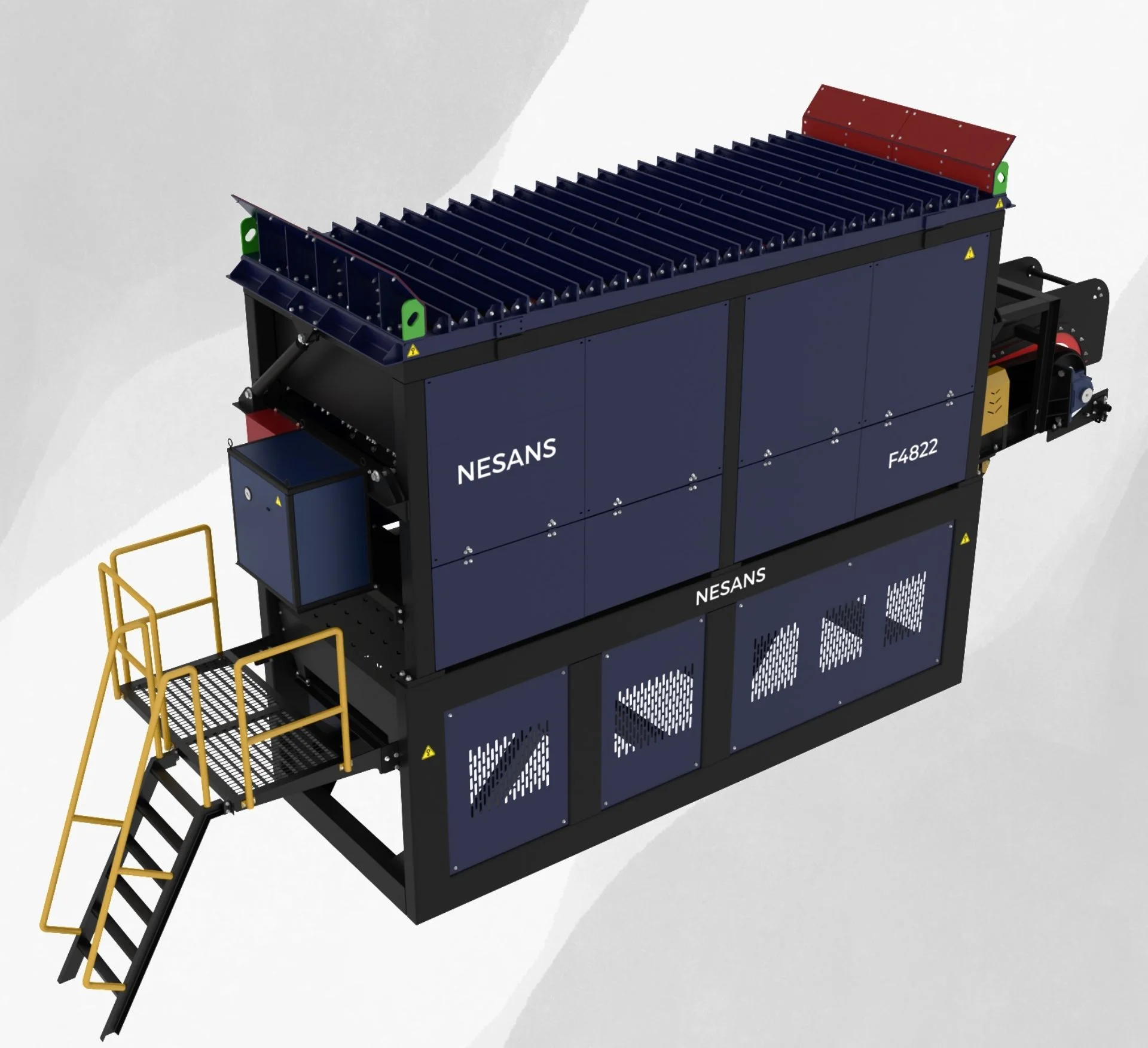

Belt Feeder - F Series

The Nesans F Series Belt Feeders are designed for controlled material feeding in a wide range of bulk handling applications including crushing, screening, and washing operations. Built with a heavy-duty frame and precision belt drive system, the F Series ensures smooth, consistent flow of material with adjustable feed rates to match process requirements.

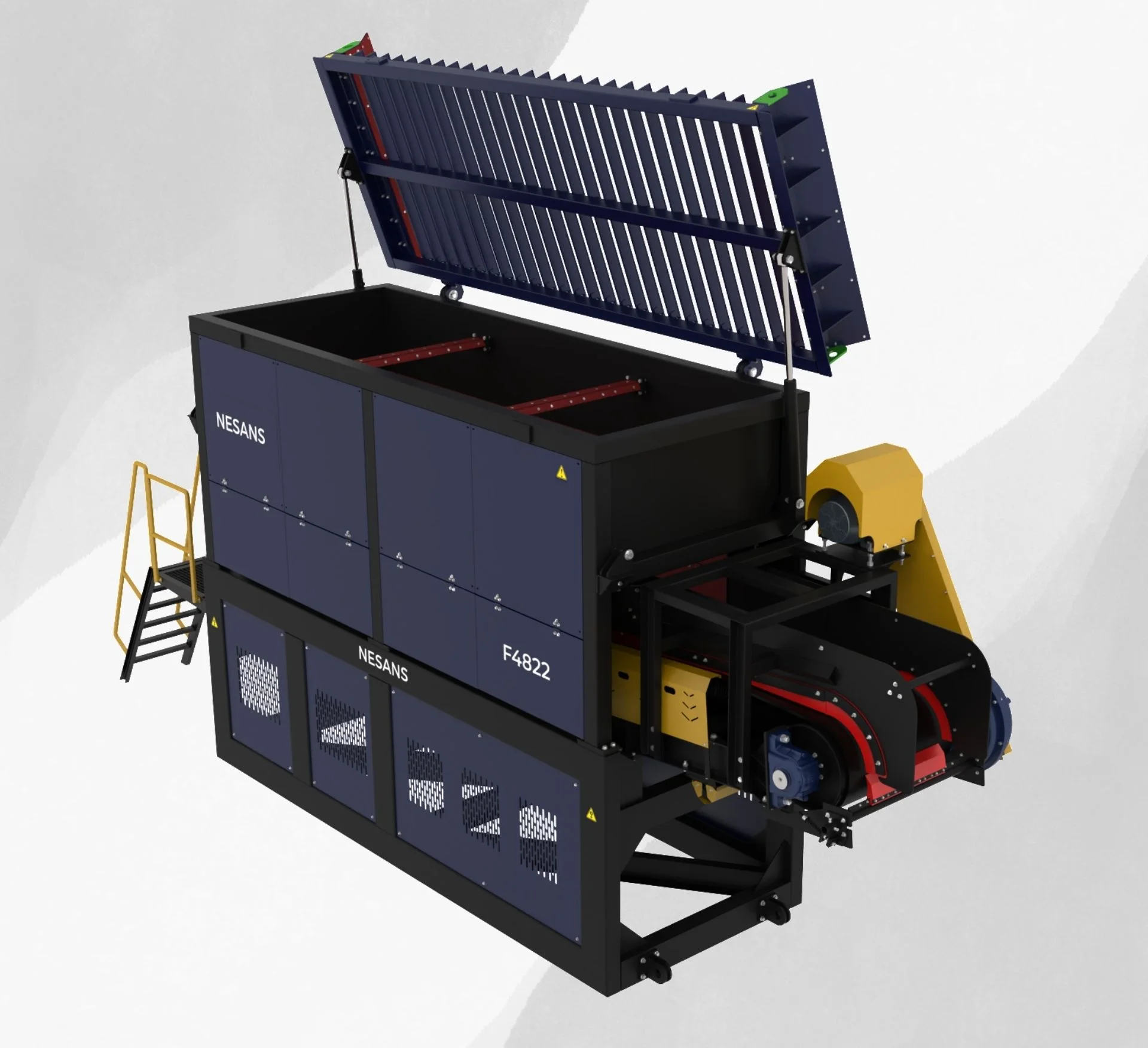

At the core of the F Series is a robust belt conveyor mechanism powered by a direct drive system that delivers high torque at low speeds, enabling precise feeding of even the most difficult materials. The feeder is enclosed with protective side panels and top covers to minimize spillage, dust generation, and external contamination, making it suitable for clean and continuous operations.

Ideal for integration beneath hoppers, surge bins, or material silos, the Nesans F Series Belt Feeders provide a dependable, wear-resistant, and low-maintenance solution for upstream material regulation. Whether you’re feeding a primary crusher or balancing the load across a processing line, the F Series delivers accuracy, reliability, and efficiency.

Applications:

How It Works

The Nesans B Series Belt Feeders ensure a controlled and uniform flow of bulk materials from storage units such as hoppers or bins onto downstream equipment. Material first passes over a grizzly deck, which pre-screens and separates oversized rocks before they reach the belt. To handle unwanted large materials, the grizzly section is equipped with hydraulic cylinders that allow it to be tipped, clearing blockages and preventing damage to the belt or downstream equipment.

Once through the grizzly, material is deposited onto a robust belt conveyor system, powered by a high-torque, low-speed drive unit. The belt moves over support rollers and is guided by a rigid frame to maintain alignment and consistent feed rate. Feed speed can be precisely adjusted to match processing requirements, offering full control over material delivery.

With options for dust suppression, spillage control, and variable speed, the B Series Belt Feeder is a versatile, heavy-duty solution for applications demanding consistent feed, equipment safety, and reduced maintenance.

Features and Advantages

Specifications

| Model No. | Hopper Size (mm) | Hopper Capacity (m³) | Max Height (m) | Belt Conveyor Length (mm) | Belt Width (mm) |

|---|---|---|---|---|---|

| F4822 | 4200 X 2400 | 12.5 | 3.3 | 6000 | 900 |

| F4825 | 5100 X 2400 | 15 | 3.3 | 7200 | 900 |

| Model No. | Hopper Size (ft) | Hopper Capacity (ft³) | Max Height (ft) | Belt Conveyor Length (ft) | Belt Width (in) |

|---|---|---|---|---|---|

| F4822 | 14 X 8 | 424 | 10.1 | 20 | 36 |

| F4825 | 27 X 8 | 530 | 10.1 | 24 | 36 |

Product Gallery

Relevant Products

Grizzly Feeder

Learn More

Vibro Feeder

Learn MoreFAQs

The feeder regulates bulk material flow from hoppers or bins. Material first passes over a grizzly deck that removes oversized rocks, then drops onto a belt conveyor powered by a high-torque, low-speed drive for uniform feeding.

Yes. With a robust frame, high-strength belt, and heavy-duty grizzly, it is built for demanding quarrying and mining environments.

It is designed for sand, aggregates, ores, coal, limestone, and other bulk solids, even when sticky, abrasive, or irregular in size.

Anywhere precise material regulation is needed: beneath hoppers, surge bins, or silos, or as a controlled feed to crushers, screens, or washers.

- Belt and splices.

- Idlers and rollers.

- Grizzly deck bars.

- Hydraulic tipping mechanism.

Yes. The heavy-duty frame and torque-rich drive allow the feeder to operate consistently even under fluctuating feed rates or surges.

It provides high torque at low speeds, allowing accurate control over material flow while reducing mechanical losses and maintenance compared to chain or gear-driven systems.

Yes. The hydraulic tipping grizzly allows oversized rocks to be discharged safely, avoiding downtime.

Its direct drive system has fewer moving parts, reducing breakdown risk, while the enclosed structure prevents dust and contamination, minimizing cleaning and wear.

By delivering a controlled, steady flow, it prevents crusher choking, screen overloading, or uneven washing, which reduces wear and improves efficiency.

It is enclosed with protective side panels and top covers, which minimize spillage, dust generation, and contamination — ensuring a cleaner working environment.

Yes. By preventing crusher blockages, minimizing spillage/dust, and reducing unnecessary wear, it lowers maintenance costs and downtime across the entire plant.

- Daily: Check belt alignment and spillage.

- Weekly: Inspect rollers and scrapers.

- Monthly: Check motor, direct drive system, and belt tension.

- Belt Feeder: Provides precise feed control and handles sticky or fine materials better.

- Vibrating Feeder: Good for scalping and handling very large lumps, but less precise in flow control.

- Quarry primary crusher feeding.

- Mining and mineral processing.

- Power plants (coal and biomass feed).

- Bulk storage and reclaim systems.

- Recycling and C&D material handling.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.