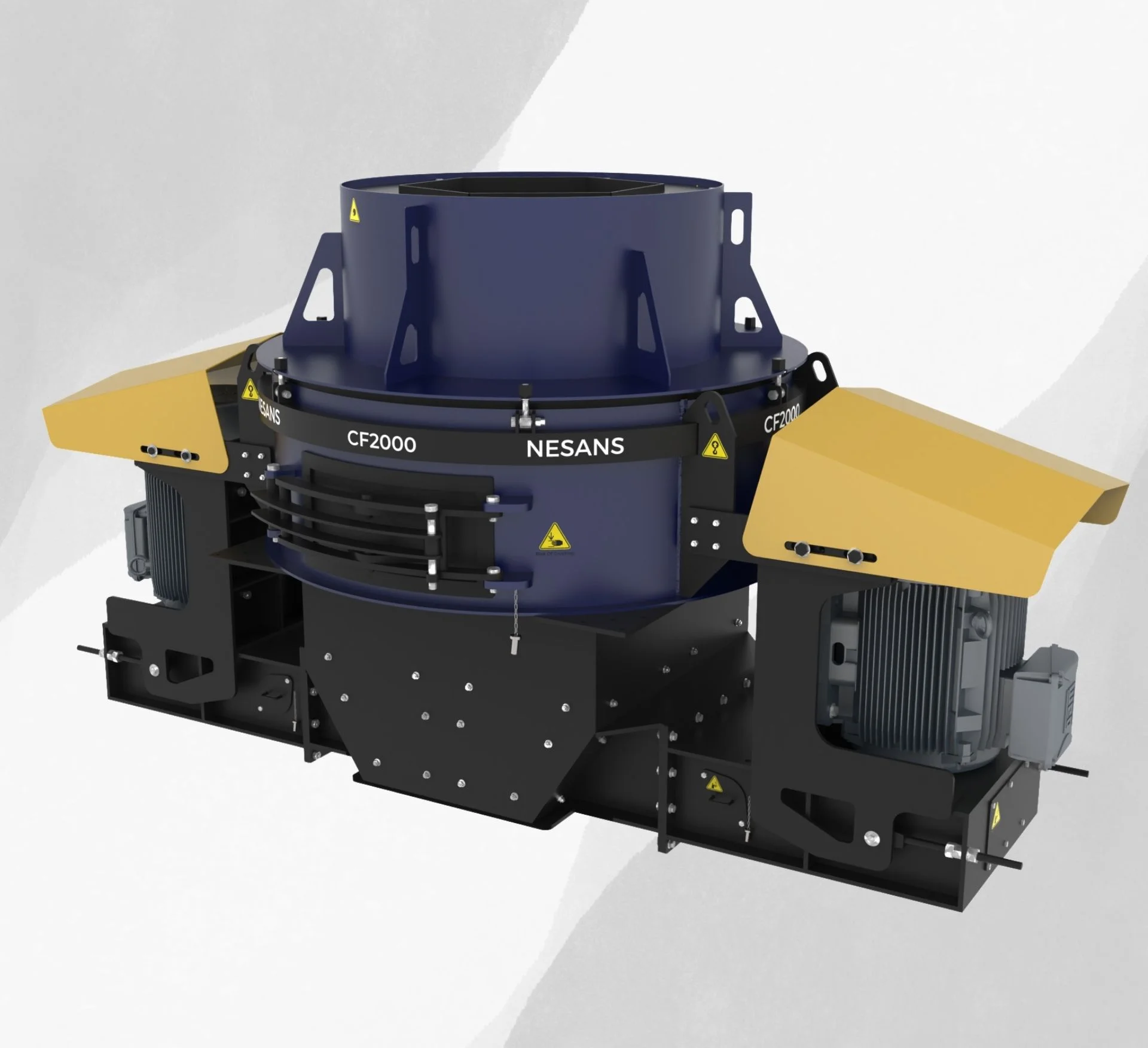

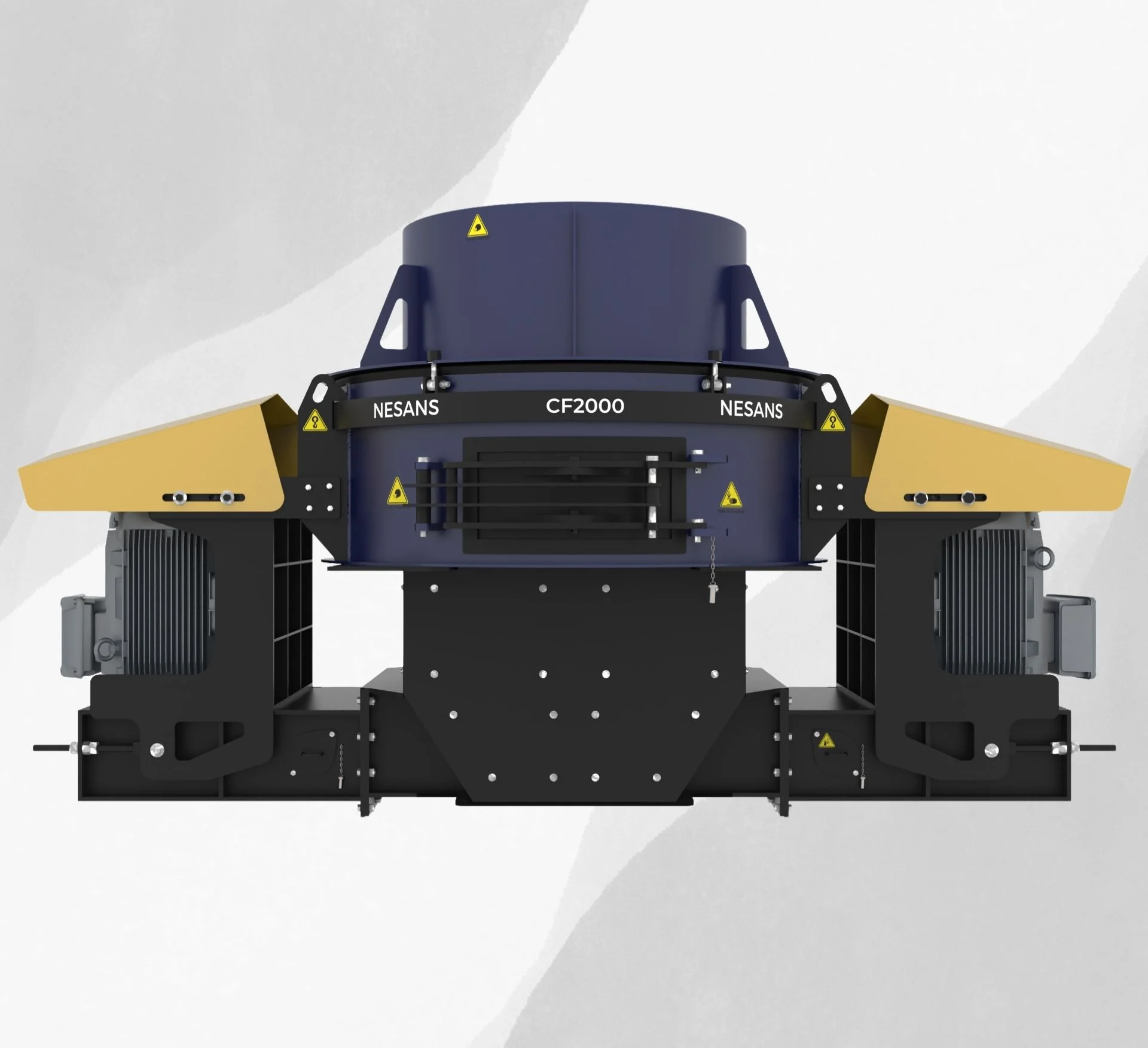

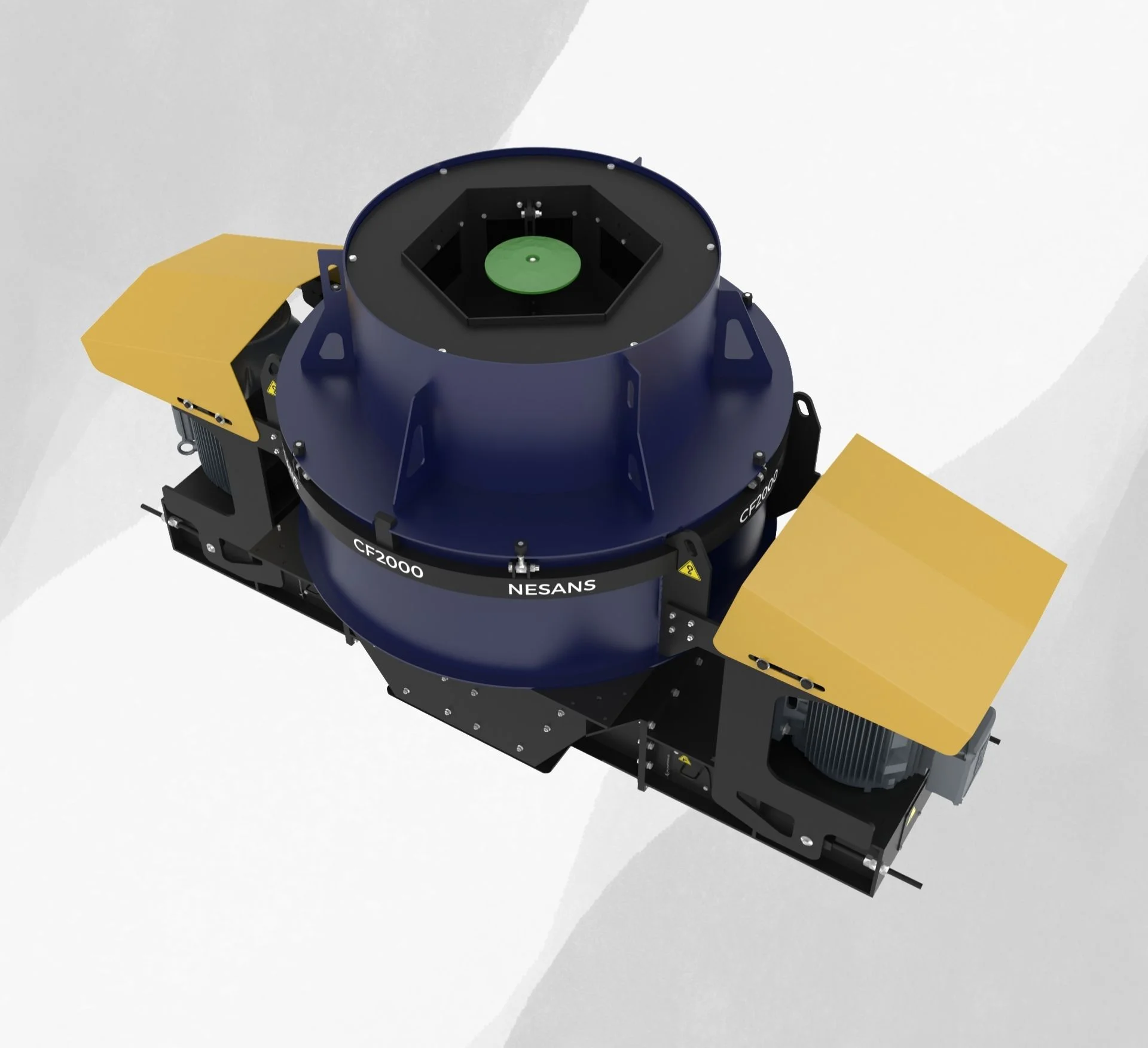

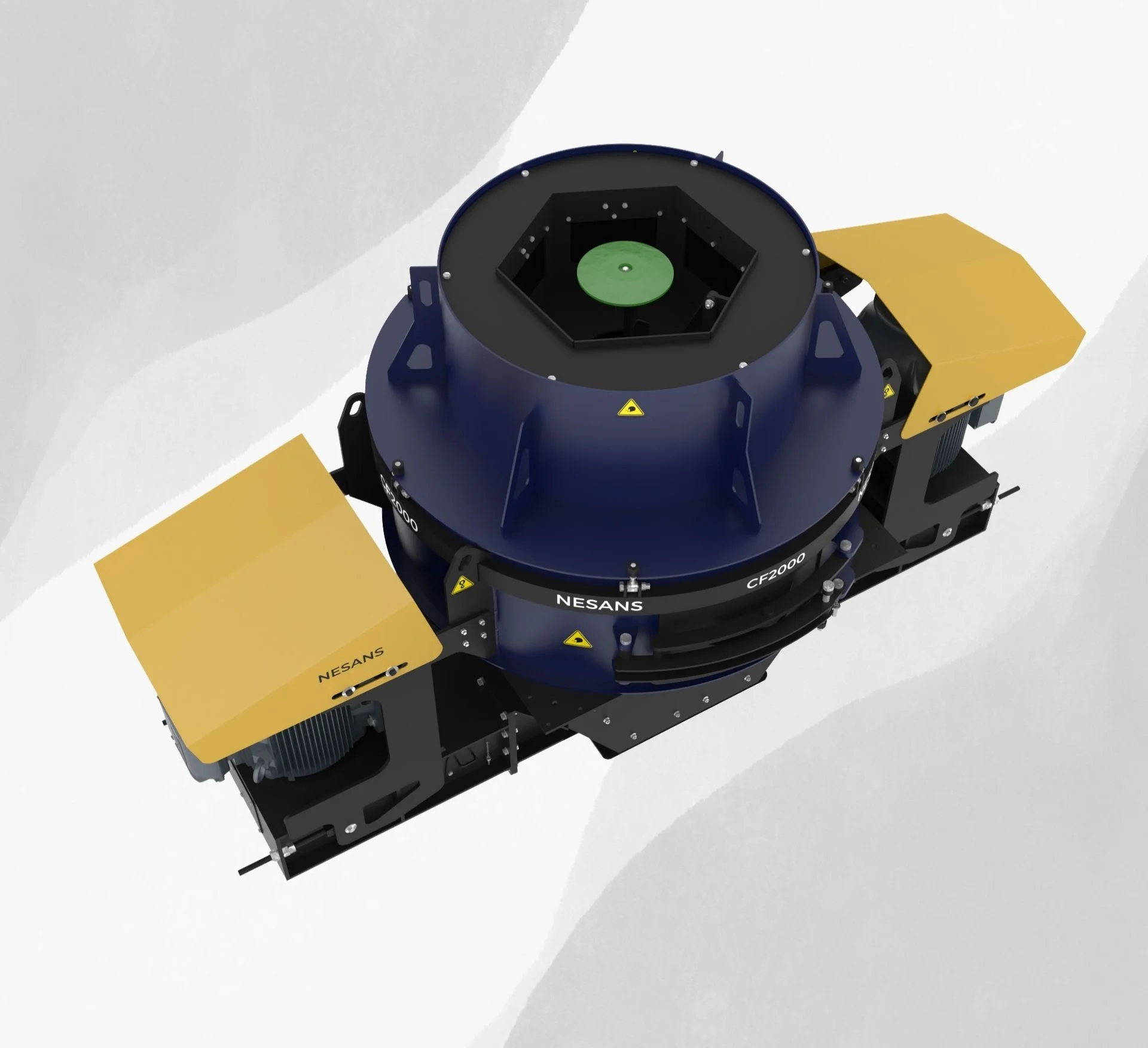

VSI Crusher - CF Series

The Nesans CF Series Vertical Shaft Impact (VSI) Crushers are designed to deliver high-quality manufactured sand and finely shaped aggregates for the construction and infrastructure industries. Operating on the principle of rock-on-rock impact, the CF Series ensures superior particle shape, reduced flaky content, and consistent gradation, making it ideal for use in concrete and asphalt production.

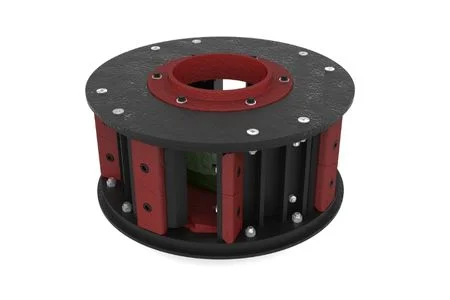

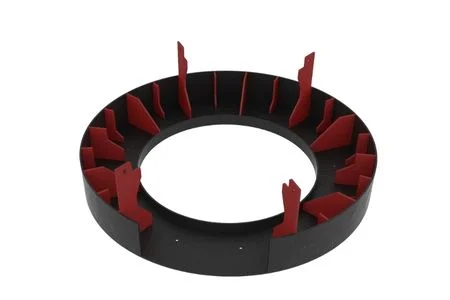

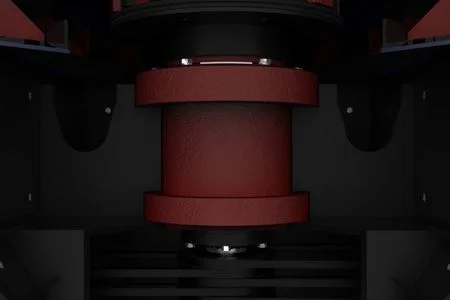

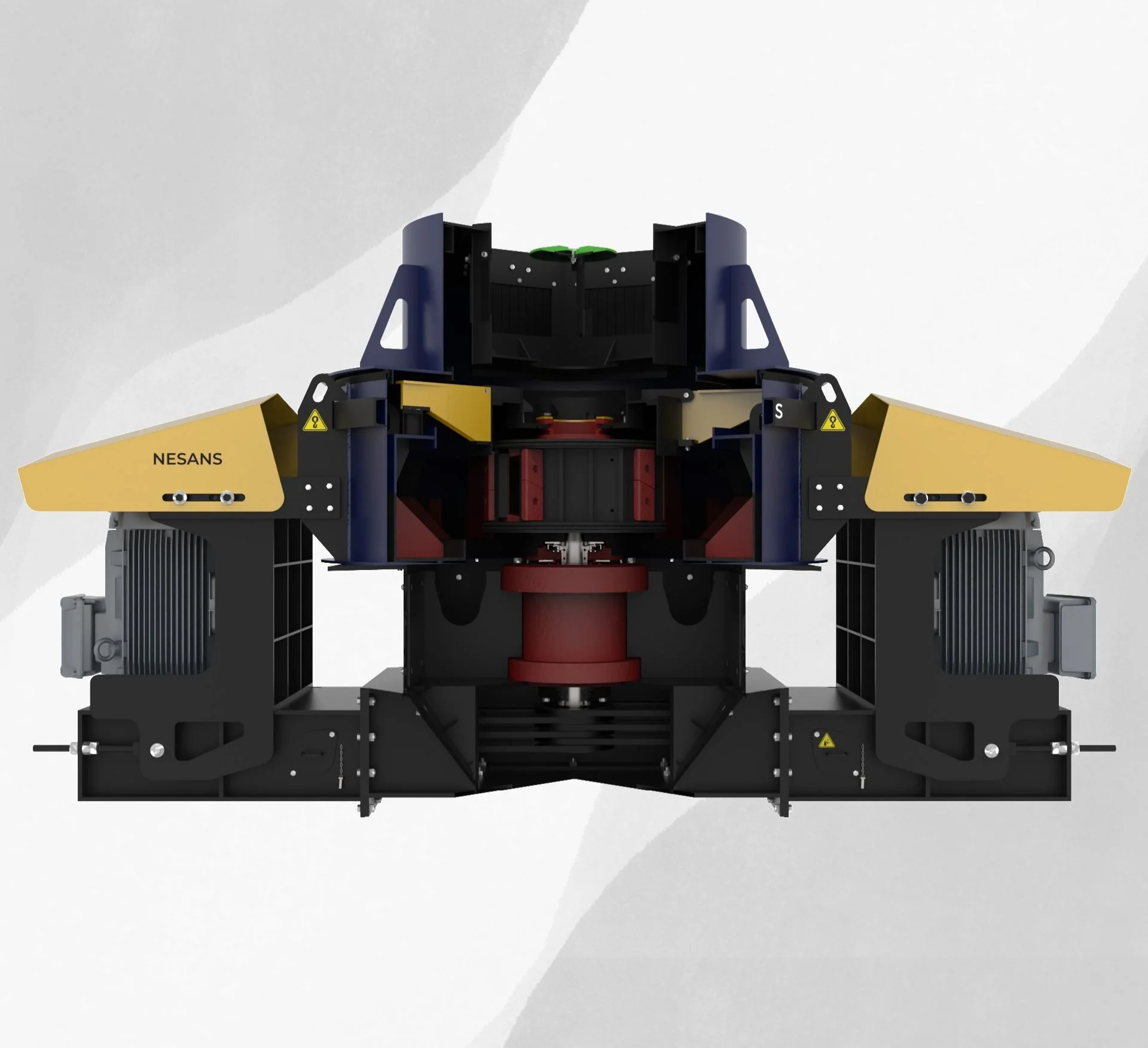

Engineered for precision and efficiency, the CF Series features a high-speed rotor that accelerates material and discharges it against a surrounding rock-lined crushing chamber. This autogenous crushing process not only minimizes wear on metallic parts but also ensures low operating costs and high output. The compact design and customizable rotor options allow the crusher to adapt to a wide range of feed materials and production requirements.

With ease of maintenance, durable components, and energy-efficient operation, the Nesans CF Series VSI Crushers offer a reliable solution for shaping and fine-crushing applications. Whether you’re producing sand or refining aggregate shape, the CF Series delivers consistent performance and long-term value.

Applications:

How It Works

The Nesans CF Series VSI Crusher operates on the principle of centrifugal acceleration and rock-on-rock impact. Material is fed centrally into the rotor, where it is rapidly accelerated to high velocity. This high-speed material is then ejected outward through the rotor ports and collides with a ring of stone lining the crushing chamber. The intense impact fractures the material into smaller, well-shaped particles while minimizing internal wear on the machine.

This autogenous crushing process not only ensures excellent particle shape and consistency but also drastically reduces the generation of fines and flaky output. The adjustable feed tube and rotor speed allow operators to fine-tune the crushing efficiency and product gradation. Combined with minimal moving parts and robust construction, the CF Series delivers smooth operation, low maintenance, and superior sand production efficiency.

Features and Advantages

Specifications

| Model No. | Max Feed Size (mm) | Motor Power (Kw) | Crusher Speed (rpm) | Crusher Weight (kg) | Capacity (mtph) | Manufactured Sand Capacity (mtPh) |

|---|---|---|---|---|---|---|

| CF500 | 30 | 55 | 1100 - 2200 | 4600 | 30 - 40 | 10 - 15 |

| CF1000 | 30 | 90 | 1100 - 2200 | 6500 | 65 - 90 | 20 - 25 |

| CF1500 | 35 | 160 | 1100 - 2200 | 9500 | 90 - 130 | 30 - 40 |

| CF2000 | 40 | 200 | 1100 - 2200 | 9800 | 110 - 170 | 45 - 60 |

| CF2500 | 45 | 300 | 1000 - 1800 | 12100 | 140 - 210 | 60 - 80 |

| CF3000 | 55 | 400 | 1000 - 1800 | 12300 | 170 - 265 | 85 - 110 |

| Model No. | Max Feed Size (in) | Motor Power (Hp) | Crusher Speed (rpm) | Crusher Weight (lb) | Capacity (stph) | Manufactured Sand Capacity (stph) |

|---|---|---|---|---|---|---|

| CF500 | 1 | 75 | 1100 - 2200 | 10141 | 33 - 44 | 11 - 17 |

| CF1000 | 1 | 120 | 1100 - 2200 | 14330 | 72 - 99 | 22 - 28 |

| CF1500 | 1 | 210 | 1100 - 2200 | 20944 | 99 - 143 | 33 - 44 |

| CF2000 | 2 | 270 | 1100 - 2200 | 21605 | 121 - 187 | 50 - 66 |

| CF2500 | 2 | 400 | 1000 - 1800 | 26675 | 170 - 265 | 66 - 88 |

| CF3000 | 2 | 500 | 1000 - 1800 | 27116 | 187 - 292 | 94 - 121 |

Product Gallery

Relevant Products

FAQs

A VSI crusher is primarily used for tertiary and quaternary crushing. After a jaw crusher and a cone crusher have reduced large rocks to smaller aggregate, the VSI is used to create the final, high-quality product. Its main application is to produce manufactured sand (M-sand) and to shape aggregates to meet stringent quality standards for high-strength concrete and asphalt used in construction projects.

We deploy VSIs as tertiary or quaternary machines to make manufactured sand (M-sand) and to improve shape on aggregates. Typical flows are Jaw → Cone → VSI → Screen/Wash or Jaw → VSI (sand only) when rock and targets allow.

Best for hard to medium-hard rock (granite, basalt, gneiss) and limestone when you need premium shape/sand. Not ideal for very wet, sticky, or dirty feeds—high moisture and clay reduce stability and raise recirculating load.

The primary wear parts of a VSI crusher are its rotor tips, anvil rings, and other internal liners. The wear rate is highly dependent on the abrasiveness of the material being crushed.

- ROR (autogenous): best shape, consistent sand, typically lower wear in abrasive granite/basalt.

- Anvil / ROS: higher reduction and more fines on softer stone; wear rises on abrasive rock.

- Recommended feed size: Below 40 mm.

- Oversized feed (>50 mm) can:

- Cause rotor imbalance.

- Reduce throughput.

- Increase wear costs.

A proper screening or secondary crushing stage is usually added before VSI to ensure optimum performance.

VSI crushers usually achieve reduction ratios of 4:1 to 8:1. However, unlike cone crushers, the goal is not maximum reduction but shaping and consistent gradation.

- Upstream: a steady feeder and screen split to keep oversize out and stabilize load.

- Downstream: screens at critical splits (e.g., 4.75 / 2.36 mm) and a classifier/wash to control FM/−75 µm, with conveyor capacity for realistic recirculation.

For consistent commercial sand, yes—especially on granite/basalt. We pair our VSIs with air classifiers (dry plants) or hydrocyclone + dewatering (wet plants) to hold FM and silt within spec year-round.

Each crusher has its role:

- Cone Crushers are excellent for secondary and tertiary reduction of hard, abrasive stones but often produce flaky particles.

- HSI Crushers work well with softer materials and generate higher fines, but the product shape is not always cubical.

- VSI Crushers are best when your project requires:

- Cubical sand and aggregates for stronger concrete and asphalt.

- Consistent gradation with fewer elongated or flaky particles.

- Flexibility to produce both sand and shaped aggregates.

In short, VSI is the preferred choice for quality-driven projects where particle shape matters more than just reduction.

VSI crushers are simple to maintain if monitored properly:

- Daily checks: Feed distribution, rotor wear tips, oil circulation.

- Weekly checks: Wear plates, anvils/rock shelves.

- Scheduled service: Lubrication system and rotor balancing.

By maintaining these, a VSI crusher can deliver continuous, reliable operation with predictable wear part costs.

- Manufactured Sand (M-sand) Production: Essential for modern construction, replacing river sand.

- Shaping Aggregates: Improves the geometry of coarse aggregates, making them cubical for asphalt and RMC (Ready-Mix Concrete).

- Recycling: Useful for re-crushing waste materials such as glass, slag, and industrial by-products.

- Industrial Minerals: Processing silica sand, quartz, and other minerals requiring uniform particle sizes.

Yes. Although VSI wear parts need periodic replacement, you save money because:

- Less cement and bitumen are needed to achieve target strength.

- Customers often pay a premium for cubical, well-graded M-sand.

- Better particle shape reduces rejection in asphalt and concrete plants.

- When you want to produce manufactured sand (M-sand) for concrete or plaster.

- When your aggregates are too flaky or elongated and need reshaping.

- When you want better packing density in asphalt and concrete mixes.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.