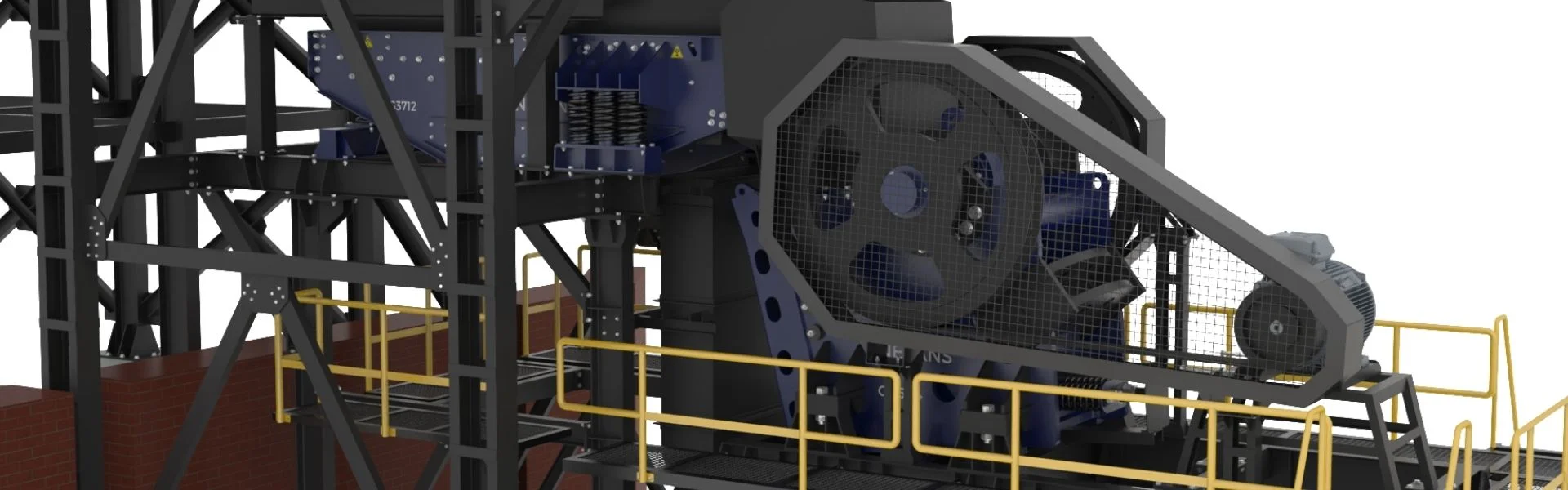

Jaw Crushers - CH Series

Engineered for performance, built to endure — the CH Series Jaw Crushers set a new standard in primary crushing.

Designed to handle the toughest materials with unmatched efficiency, this series combines robust construction, innovative design, and cutting-edge technology to deliver maximum productivity in every operation.

Whether you’re processing hard granite, abrasive minerals, or recycled materials, the CH Series ensures superior reduction ratios, consistent output, and minimal downtime.

Backed by precision manufacturing and decades of engineering excellence, these jaw crushers are the trusted choice for mining, quarrying, and aggregate applications. Step into the future of crushing — where strength meets precision with the CH Series.

Applications:

How It Works

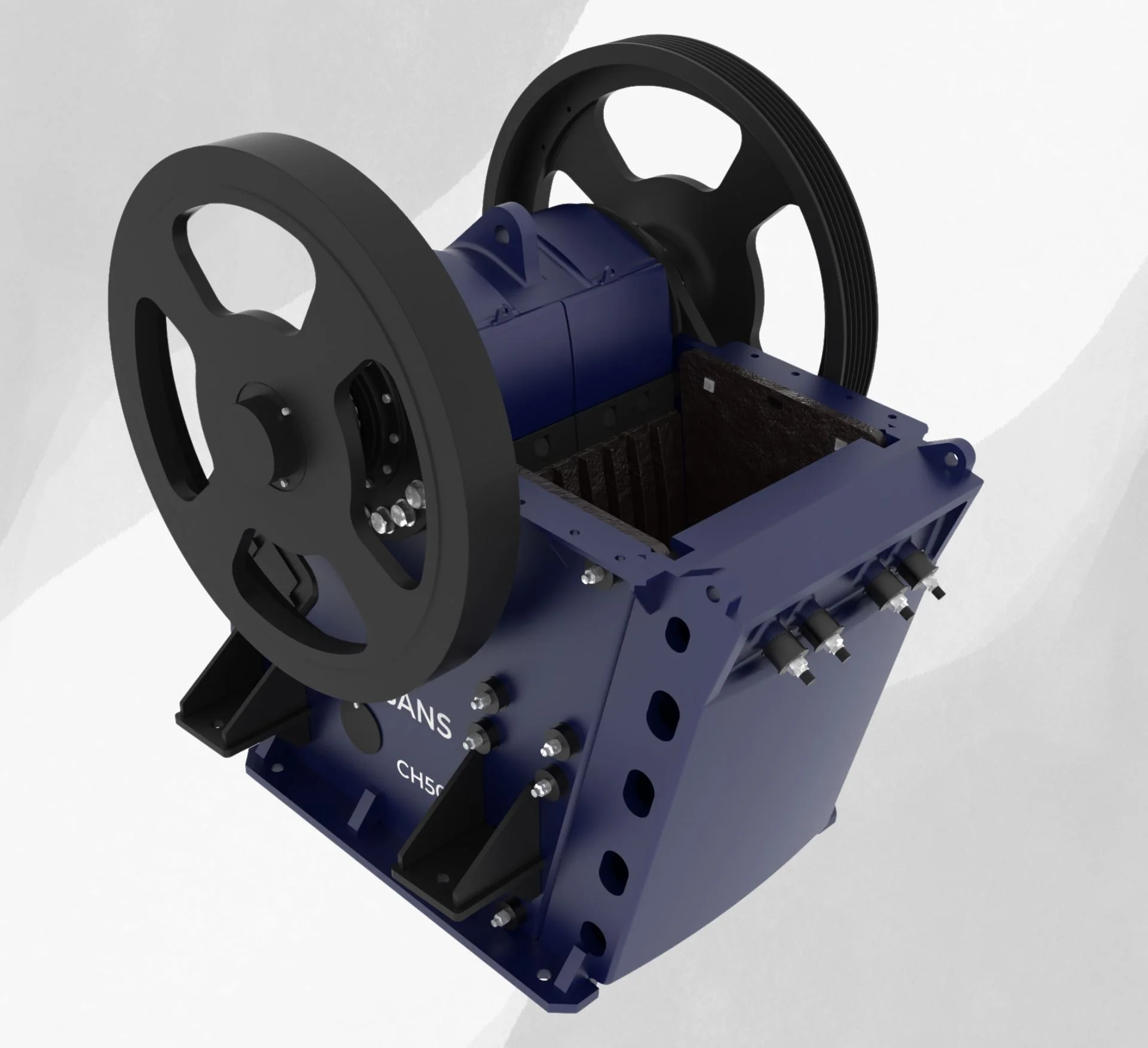

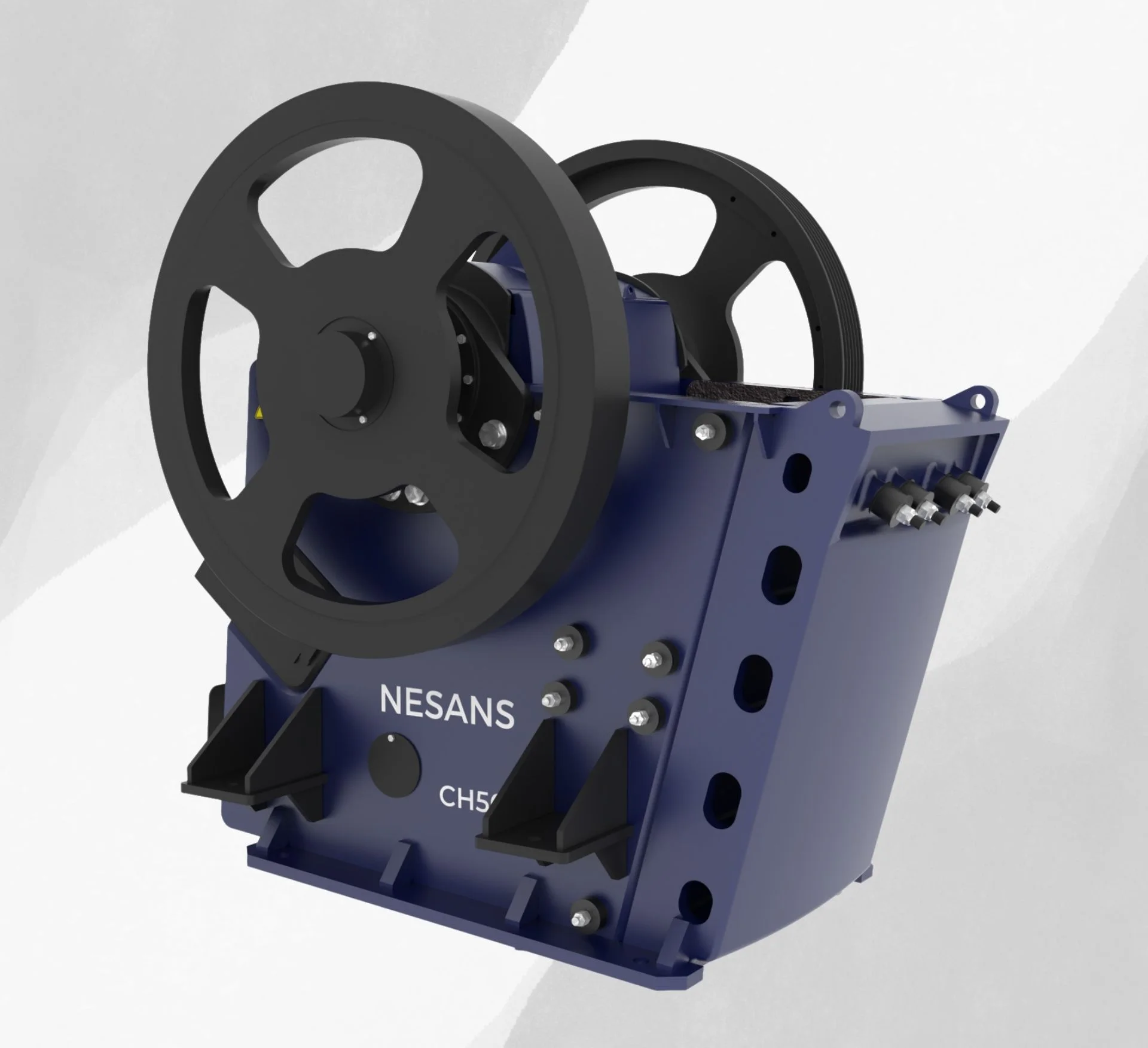

The CH Series Jaw Crusher operates using a simple yet powerful principle — material is fed into a V-shaped chamber formed by a fixed jaw and a moving jaw. As the moving jaw oscillates back and forth through an eccentric motion, it crushes the material against the fixed jaw.

This process continues until the crushed material is small enough to pass through the discharge opening at the bottom. The result is efficient, consistent size reduction with minimal downtime.

Built for heavy-duty applications, the CH Series combines strength with precision engineering. Its rugged design ensures long service life even in the toughest crushing environments.

Features and Advantages

Specifications

| Model No. | Feed Opening (mm) | Max Feed Size (mm) | CSS Range (mm) | Motor Power (Kw) | Jaw Plates (Config) | Crusher Weight (kg) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| CH192S | 600 X 400 | 250 | 20 - 60 | 37 | Bidirectional | 8000 | 30 - 70 |

| CH504 | 900 X 700 | 600 | 50 - 175 | 75 | Carbon-Copy & Bidirectional | 14000 | 100 - 120 |

| CH736 | 1050 X 850 | 750 | 75 - 225 | 110 | Carbon-Copy & Bidirectional | 21000 | 150 - 200 |

| CH905 | 1250 X 980 | 830 | 100 - 250 | 160 | Bidirectional | 32000 | 250 - 500 |

| Model No. | Feed Opening (in) | Max Feed Size (in) | CSS Range (in) | Motor Power (Hp) | Jaw Plates (Config) | Crusher Weight (lb) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| CH192S | 24 X 16 | 10 | 0.8 - 2.5 | 50 | Bidirectional | 17637 | 33 - 77 |

| CH504 | 36 X 28 | 48 | 2 - 7 | 100 | Carbon-Copy & Bidirectional | 30865 | 110 - 132 |

| CH736 | 42 X 34 | 30 | 3 - 9 | 150 | Carbon-Copy & Bidirectional | 46297 | 165 - 220 |

| CH905 | 49.2 X 38.5 | 32.7 | 4 - 10 | 215 | Bidirectional | 70548 | 275 - 550 |

Product Gradation Curves

Particle size distribution at different Closed Side Settings (CSS)

Product Gallery

Relevant Products

Vertical Shaft Impact Crusher

Learn More

Horizontal Shaft Impact Crusher

Learn More

Cone Crusher

Learn MoreFAQs

A jaw crusher is a primary crushing machine that uses compressive force to break down large rocks, ores, and other hard materials into smaller, more manageable pieces. It is commonly used in mining, quarrying, construction, and recycling industries.

Key components of a jaw crusher include:

- Fixed and Movable Jaw Plates: The wear parts that directly crush the material. They are typically made of high-manganese steel for durability.

- Pitman: The main moving part that holds the movable jaw. It is driven by the eccentric shaft.

- Eccentric Shaft: A rotating shaft with an offset section that creates the back-and-forth motion of the pitman.

- Flywheel: A heavy wheel that stores and releases rotational energy to ensure smooth operation and consistent crushing force.

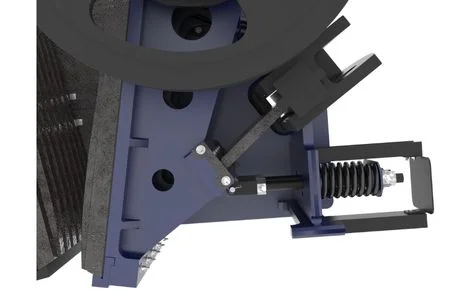

- Toggle Plate: A safety mechanism that connects the pitman to the crusher frame. It is designed to break if an uncrushable object (tramp iron) enters the chamber, protecting more expensive components.

- Frame: The main structural body of the crusher that supports all other components.

- Adjustment System: A mechanism (often a wedge or hydraulic system) used to change the size of the discharge opening, thereby controlling the size of the final product.

Jaw crushers are the workhorses of the industry, used almost exclusively as primary crushers. They are designed to handle large, raw feed materials like boulders from a quarry. Their main application is to take very hard and abrasive materials like granite, basalt, and ores and reduce them to a smaller, more manageable size for further processing by another crusher. They are a staple in mining, quarrying, and large-scale aggregate production plants.

- Wear parts: Jaw plates, cheek plates (liners), toggle plates, and flywheel shaft bushings.

- Replacement frequency: Highly dependent on material hardness and usage; jaw plates may last anywhere from 500 to 2,000 operating hours.

- Monitoring: Regularly measure wear by thickness and replace once reduction in performance or excessive wear is observed.

- Feed material: Hard or abrasive materials such as granite, basalt, quartz, river pebble, copper ore, iron ore, limestone, and construction waste.

- Maximum feed size: Typically up to 80% of the crusher’s feed opening (e.g., a 600 × 400 mm crusher handles feeds up to ~500 mm).

- Output size range: Adjustable via the discharge gap; typically 10–100 mm depending on the model and setting.

Often yes. It bypasses fines, smooths surges, removes trash, and protects the jaw—increasing throughput and reducing wear.

A jaw crusher is the usual primary machine: it takes big, blocky run-of-mine rock and downsizes it by squeezing between a fixed and a swing jaw. A cone crusher typically works after the jaw, using a rotating mantle and bowl to produce a finer, more cubical product with tighter size control. Jaws tolerate larger, dirtier feed and are simpler to maintain; cones prefer pre-sized, choke-fed material and offer more adjustability

No. Jaws prefer a steady, near-full chamber, not true choke. Keep feed consistent; avoid feast-and-famine surges.

Typically 3:1 to 6:1. If you need finer control or more cubical shape, plan a cone/VSI after the jaw.

The closed-side setting (CSS) governs top size out of the jaw. Start with the smallest CSS that still avoids bridging and meets your downstream target, then fine-tune after you see the screen results.

- Single-toggle crushers:

- Lighter, more compact, higher throughput for a given size.

- Simpler mechanism—easier maintenance.

- Double-toggle crushers:

- Higher crushing force due to toggle leverage.

- Better suited for very hard, abrasive materials.

- More complex geometry—greater initial cost and slightly higher maintenance.

Yes—by removing fines ahead of it and keeping load steady, you will reduce re-handling and recirculating load, which lowers kWh/t for the whole circuit.

- High reduction ratios: Efficiently reduces large rock to manageable sizes.

- Simplicity & reliability: Fewer moving parts and robust design.

- Low operating costs: Simple maintenance and lower power consumption per tonne.

- Versatility: Handles a wide range of materials and feeding conditions.

- Excessive Wear on Jaws: This is a common issue due to the abrasive nature of the materials. Solution: Use high-quality, wear-resistant manganese steel jaws, and regularly inspect and replace them as needed. Ensure even feeding to distribute wear more uniformly.

- Crushing Chamber Jamming: Can occur with irregular or oversized feed material. Solution: Install a feeder or screen to pre-screen the material, and maintain a consistent feed rate to prevent blockages.

- Reduced Crushing Capacity: This can be caused by worn jaw plates, incorrect settings, or a clogged discharge chute. Solution: Replace worn parts, adjust settings according to manufacturer guidelines, and regularly clear the discharge area.

- Excessive Vibration or Noise: May be caused by loose bolts, worn bearings, or unlubricated parts. Solution: Regularly check and tighten all bolts, lubricate bearings, and inspect the toggle plate and other components for damage.

Yes, jaw crushers are commonly used in the recycling industry for processing materials like concrete, asphalt, and demolition waste. Their rugged compression-based design can handle tramp iron (un-crushable material like rebar) better than other crusher types, making them ideal for this tough application.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.