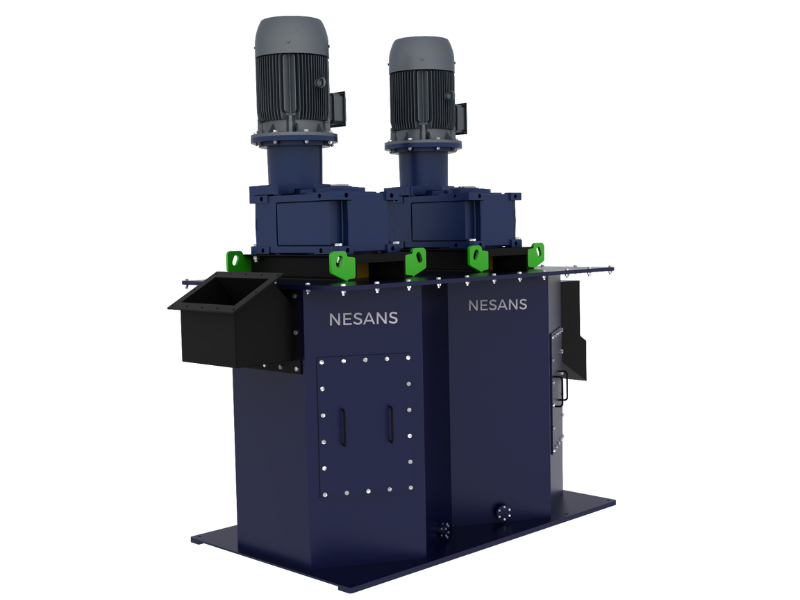

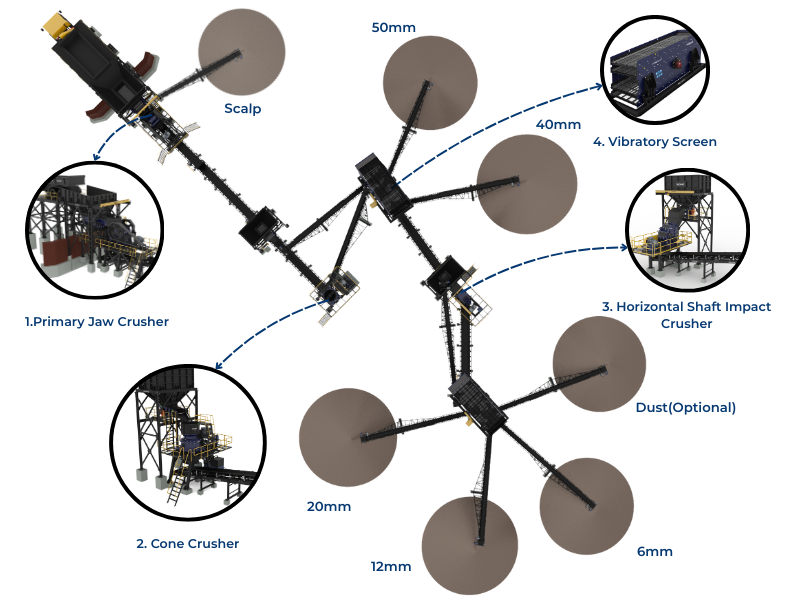

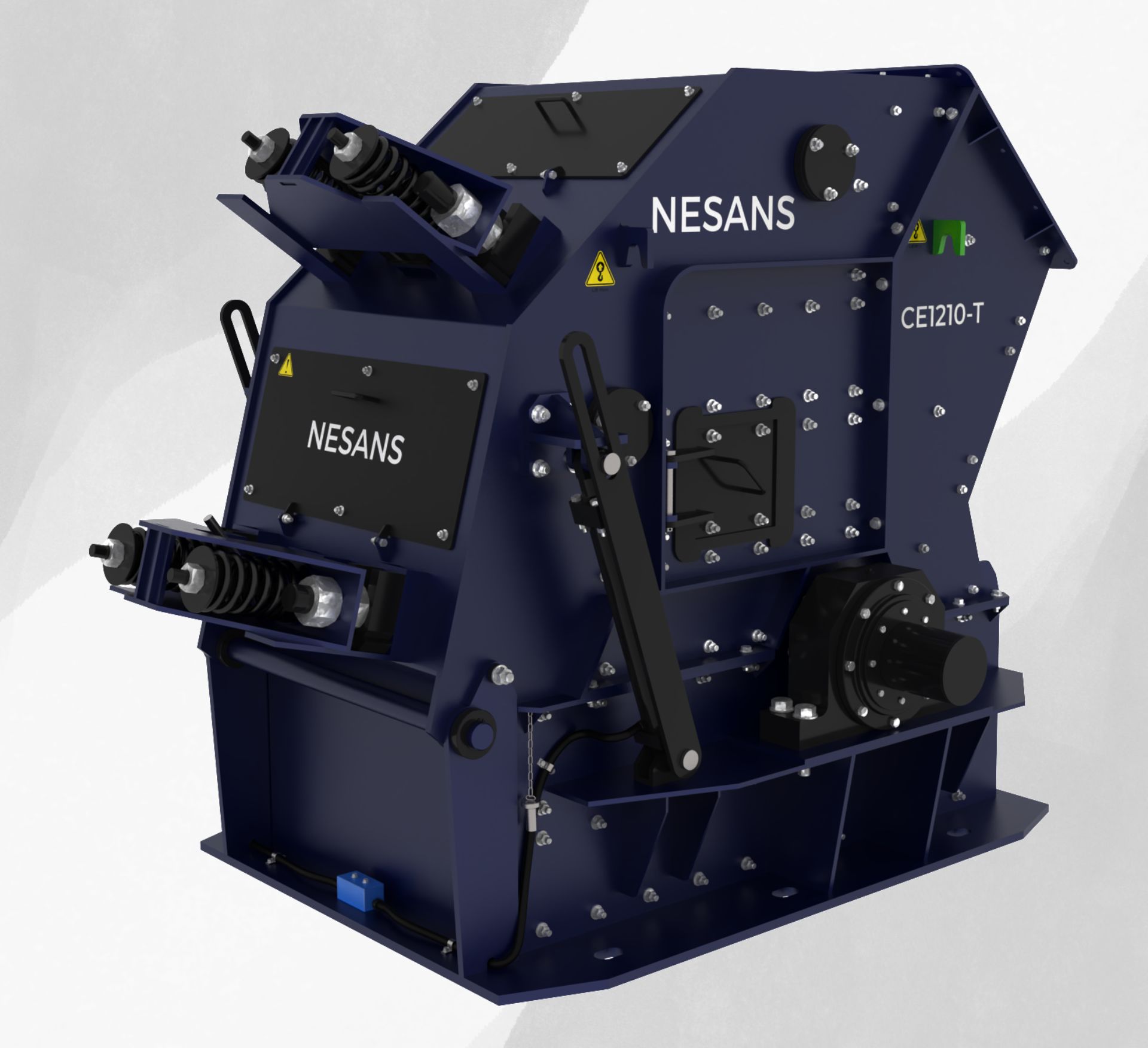

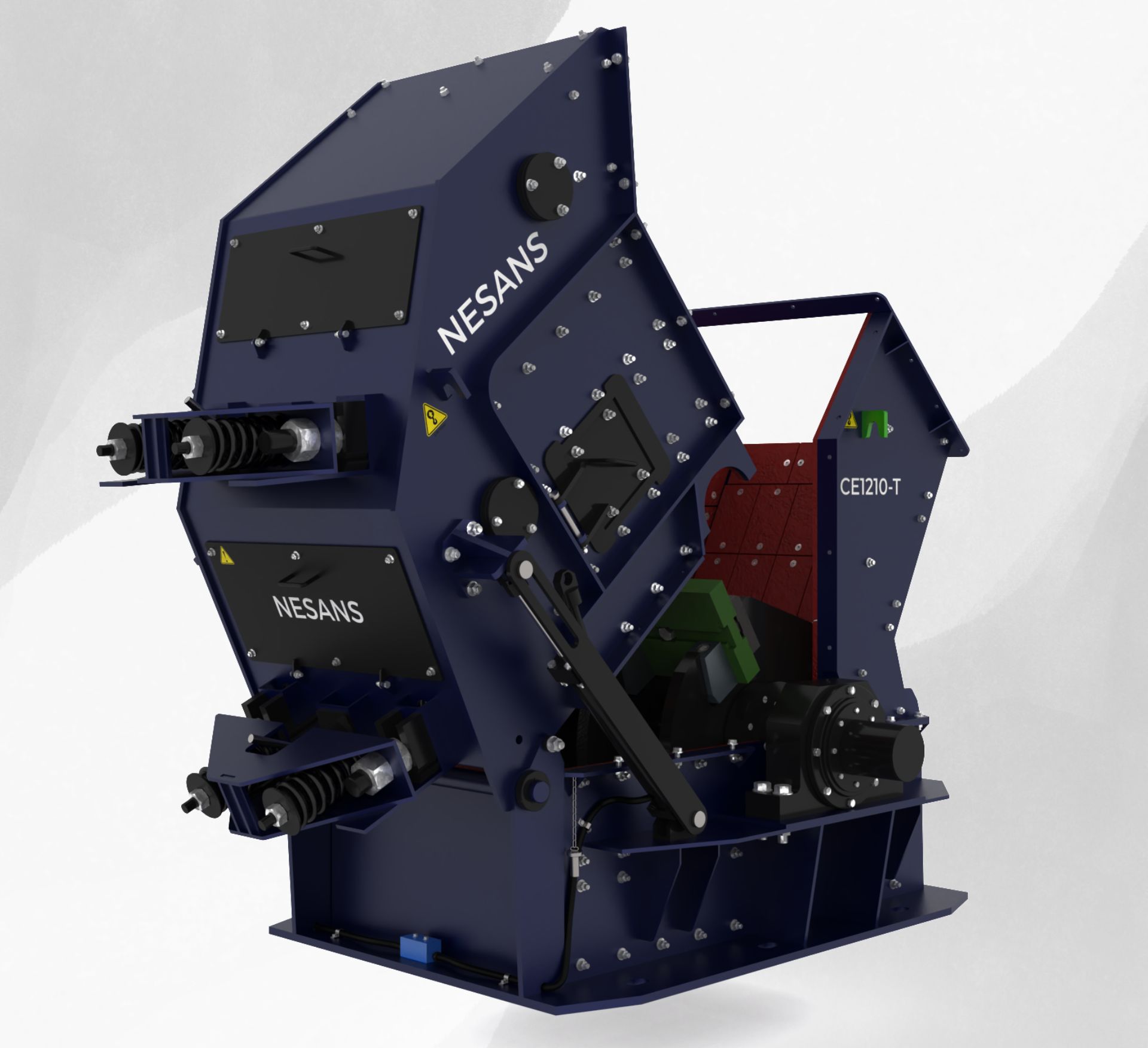

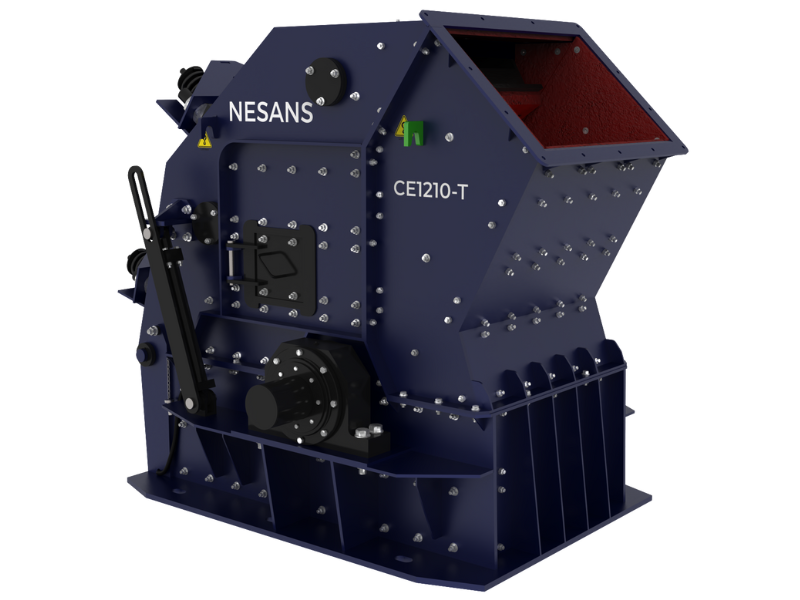

HSI Crushers - CE Series

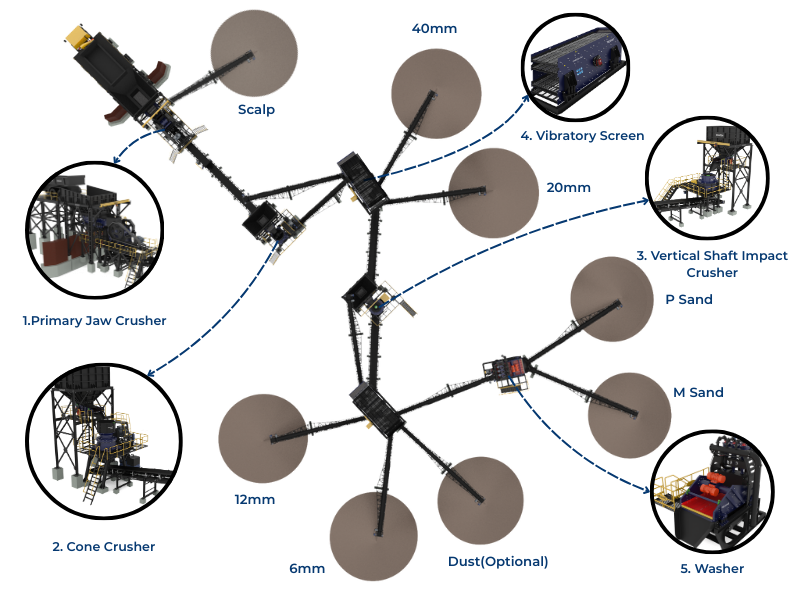

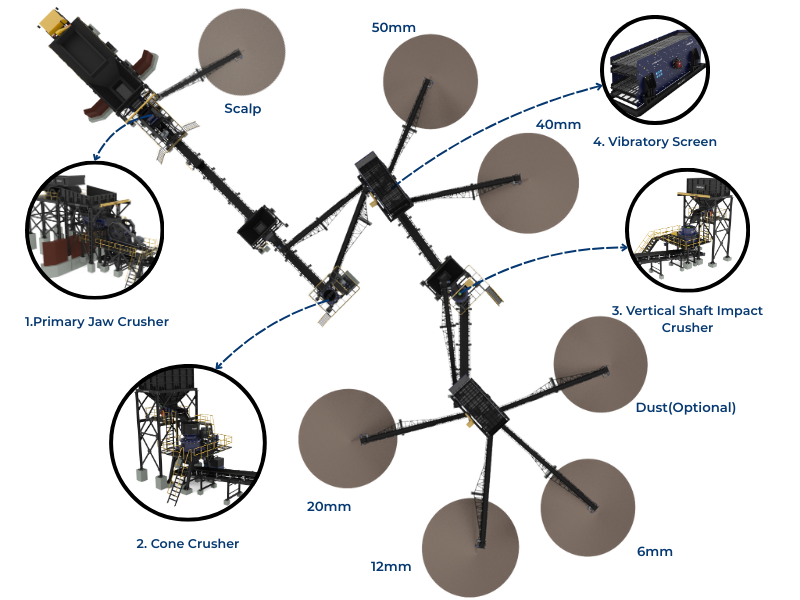

The Nesans CE Series Horizontal Shaft Impact (HSI) Crushers are specially designed to deliver superior crushing performance with unmatched efficiency and reliability. Built for heavy-duty operations, these crushers are ideal for secondary and tertiary crushing of a wide range of materials including granite, basalt, limestone, and recycled concrete. With a focus on producing well-graded, cubical end products, the CE Series is a perfect fit for modern aggregate production plants and infrastructure projects.

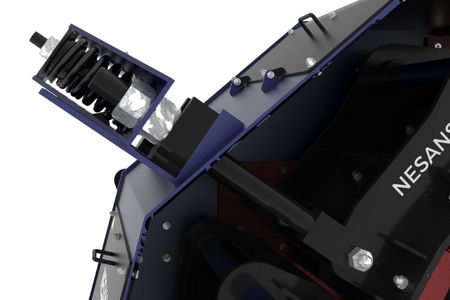

At the heart of the CE Series is a high-speed rotor system that delivers intense kinetic energy, allowing materials to be fragmented with precision. The crusher’s adjustable apron design and optimized chamber geometry ensure better control over product gradation and capacity. To enhance wear resistance and reduce operational costs, all key components are crafted from high-grade materials, while wear parts are strategically placed and easily replaceable.

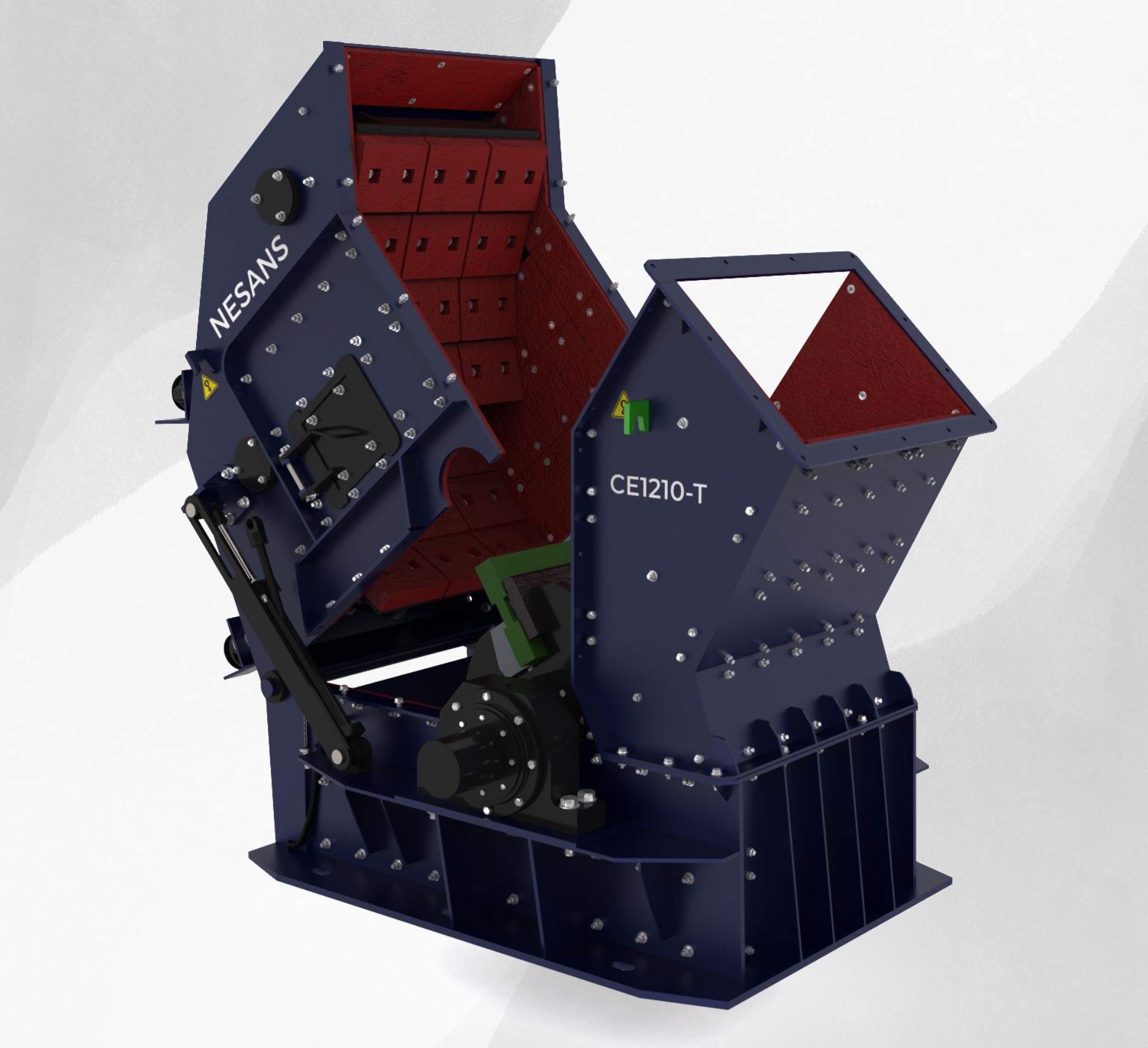

Nesans places a strong emphasis on user-friendly design and long-term value. The CE Series HSI Crushers come with hydraulic opening mechanisms, which simplify maintenance and reduce downtime significantly.

Applications:

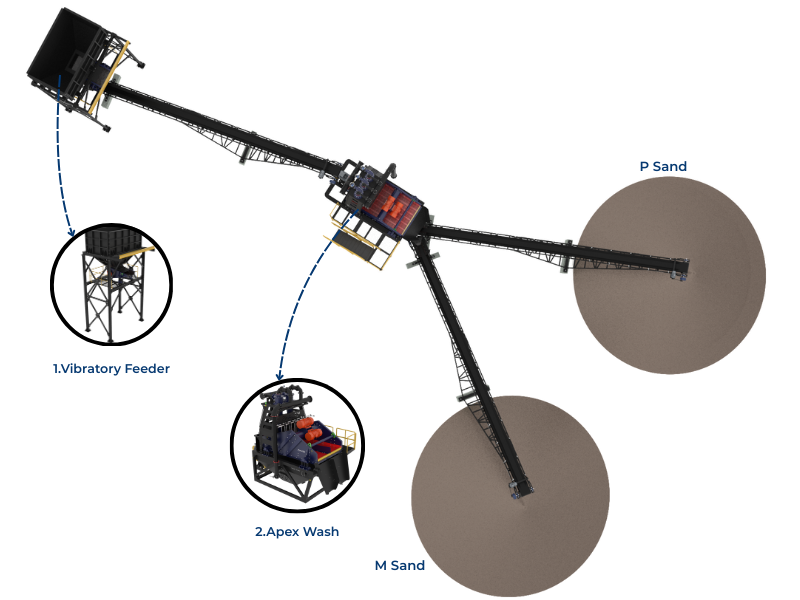

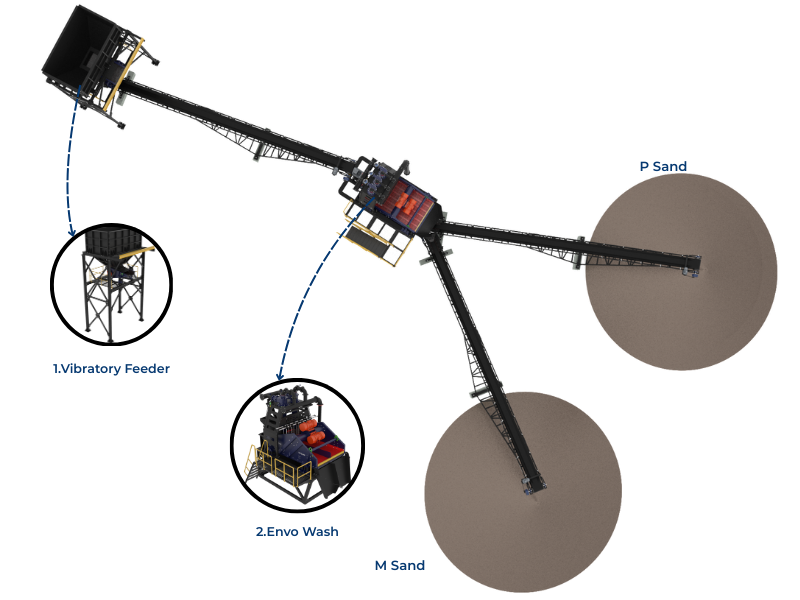

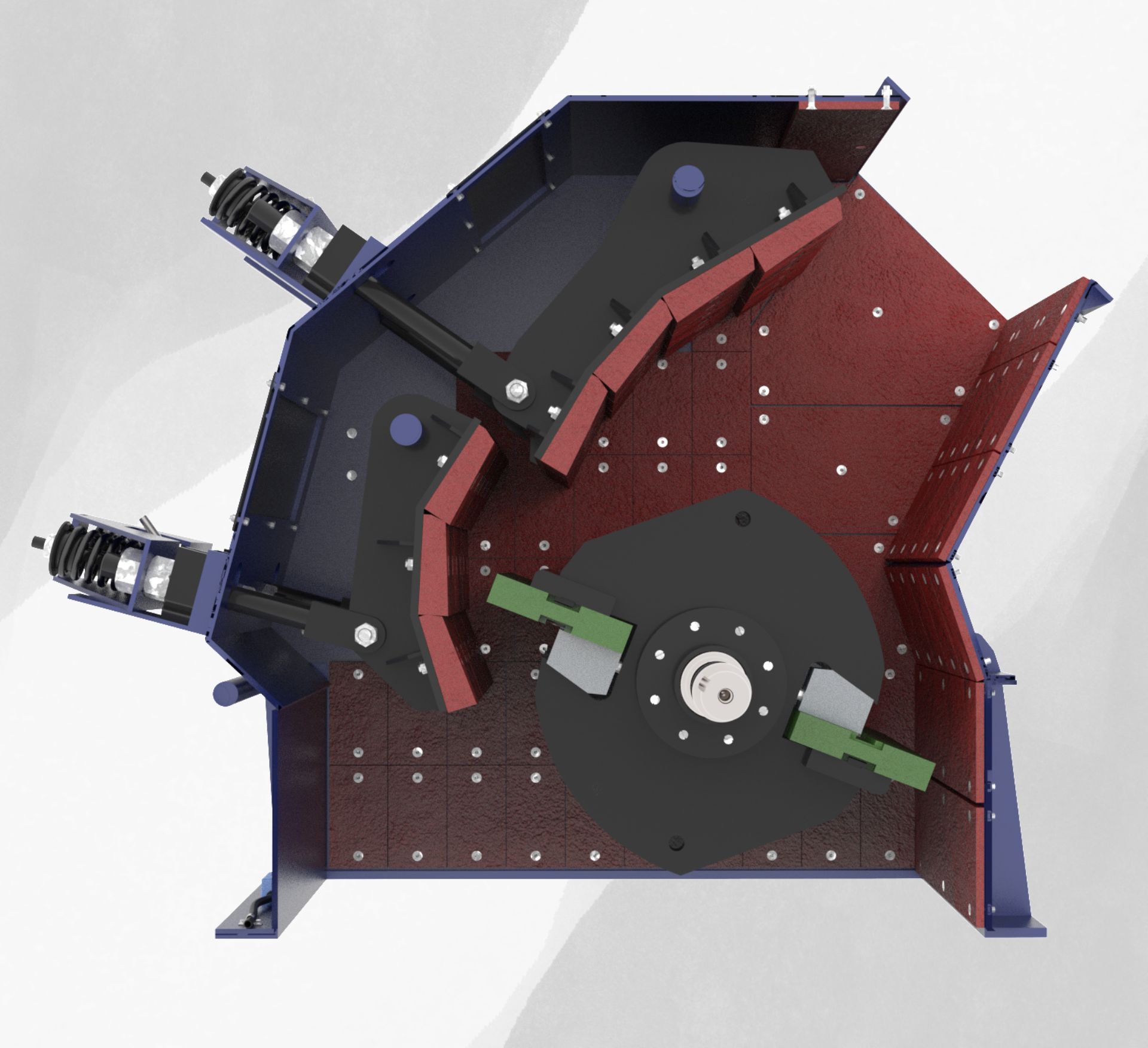

How It Works

The Nesans CE Series HSI Crusher operates on the principle of impact crushing, where material is fed into the crusher chamber and accelerated by a high-speed rotor. As the rotor spins, it flings the material outward into a series of adjustable breaker plates (aprons). These plates are strategically positioned to absorb the impact and crush the material into smaller, uniform-sized particles. The design ensures optimal rock-on-metal contact, which not only maximizes reduction ratios but also produces well-shaped, cubical aggregates ideal for concrete and asphalt applications.

Once the material has been impacted and broken down, it falls through the crushing chamber and exits via the bottom opening. The crusher’s hydraulic adjustment system allows operators to fine-tune the position of the aprons, thereby controlling the product size and shape. This system, combined with easily replaceable wear parts and robust construction, ensures consistent performance, minimal downtime, and maximum productivity across a range of feed materials and operating conditions.

Features and Advantages

Specifications

| Model No. | Feed Opening (mm) | Max Feed Size (mm) | CSS Range (mm) | Motor Power (Kw) | Crusher Speed (rpm) | Crusher Weight (kg) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| CE1210S | 400X600 | 200 | 20 - 50 | 55 | 900 | 4320 | 30-40 |

| CE3036S | 750X800 | 220 | 22 - 55 | 90 | 800 | 7240 | 75-100 |

| CE4230S | 1020X820 | 250 | 25 - 62 | 160 | 800 | 9500 | 110-150 |

| CE5252S | 1320X880 | 275 | 27 - 69 | 200 | 700 | 13110 | 165-200 |

| CE5263S | 1540X930 | 300 | 30 - 75 | 262 | 700 | 16050 | 220-250 |

| CE1210T | 400X600 | 30 | 10 - 15 | 55 | 900 | 4320 | 30-40 |

| CE3036T | 750X800 | 40 | 10 - 20 | 90 | 1000-1200 | 7240 | 75-100 |

| CE4230T | 1020X820 | 45 | 10 - 23 | 160 | 900-1100 | 9500 | 110-150 |

| CE5252T | 1320-880 | 50 | 10 - 25 | 200 | 900-1100 | 13110 | 165-200 |

| CE5263T | 1540X930 | 55 | 10 - 28 | 250 | 800-1000 | 16050 | 220-250 |

| Model No. | Feed Opening (in) | Max Feed Size (in) | CSS Range (in) | Motor Power (Hp) | Crusher Speed (rpm) | Crusher Weight (lb) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| CE1210S | 16X32 | 8 | 0.8 - 2 | 75 | 900 | 9523 | 33-44 |

| CE3036S | 30X32 | 8.8 | 0.86 - 2.1 | 120 | 800 | 15961 | 83-110 |

| CE4230S | 40X32.3 | 10 | 1 - 2.5 | 220 | 800 | 20944 | 121-165 |

| CE5252S | 52X34.6 | 11 | 1 - 2.7 | 250 | 700 | 28903 | 182-220 |

| CE5263S | 60.6X36.6 | 12 | 1.2 - 3 | 350 | 700 | 35384 | 243-276 |

| CE1210T | 16X32 | 1.2 | 0.5 - 0.6 | 75 | 900 | 9524 | 1.2 |

| CE3036T | 30X32 | 1.6 | 0.3 - 0.8 | 120 | 1000-1200 | 15961 | 83-110 |

| CE4230T | 40X32.3 | 1.8 | 0.3 - 0.9 | 220 | 900-1100 | 20944 | 121-165 |

| CE5252T | 52-34.6 | 2 | 0.3 - 1 | 250 | 900-1100 | 20903 | 182-220 |

| CE5263T | 60.6X36.6 | 2.2 | 0.3 - 1.1 | 350 | 800-1000 | 32384 | 243-276 |

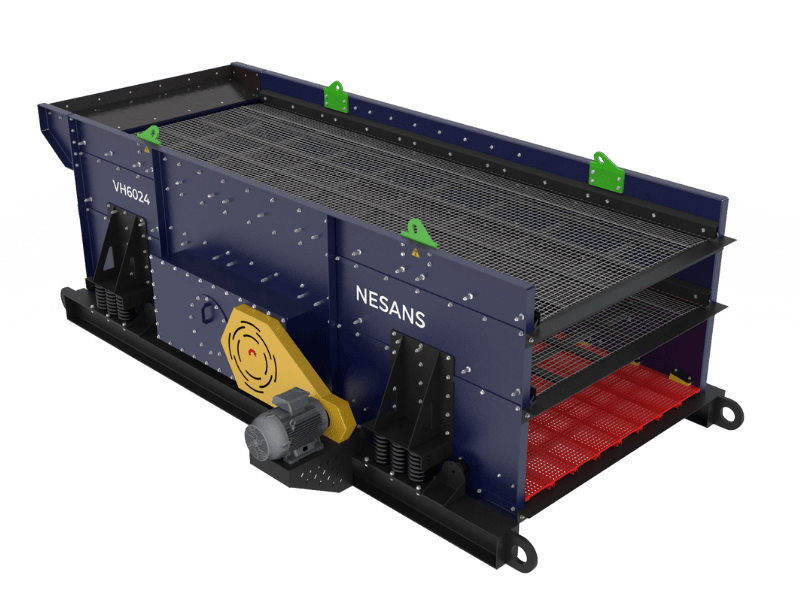

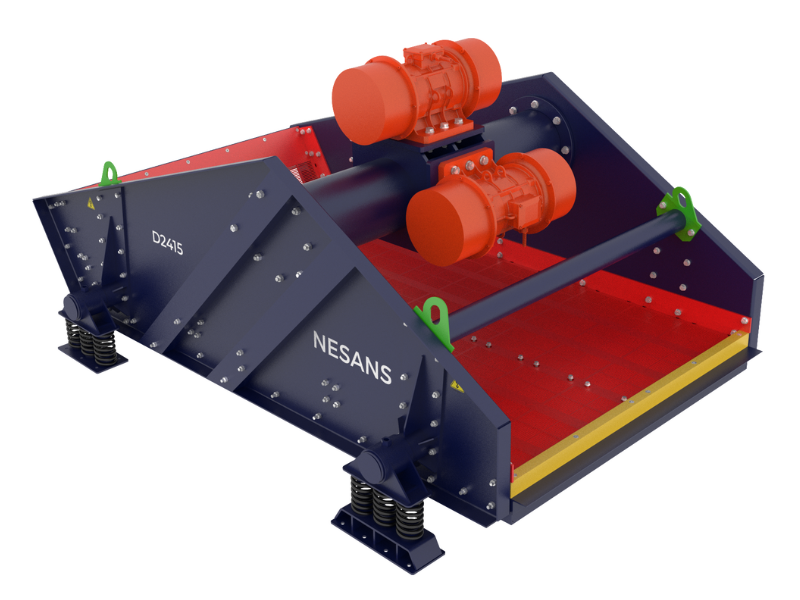

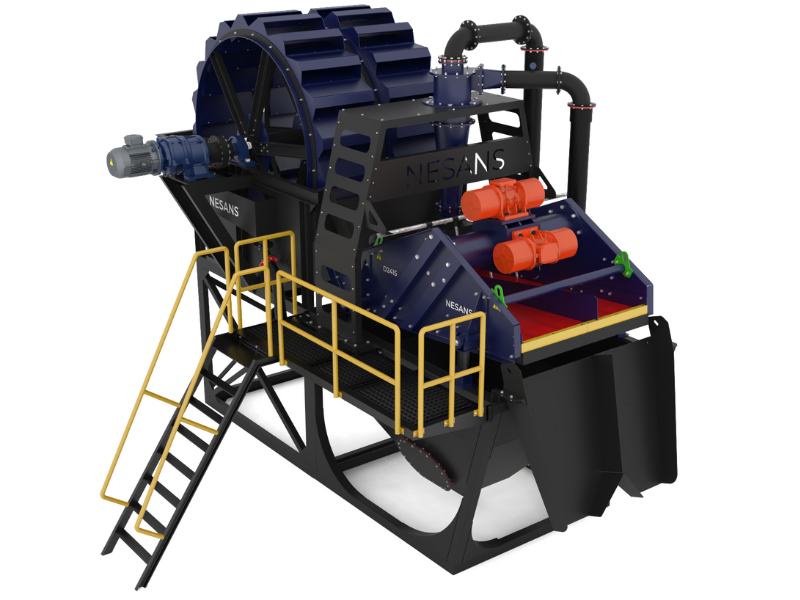

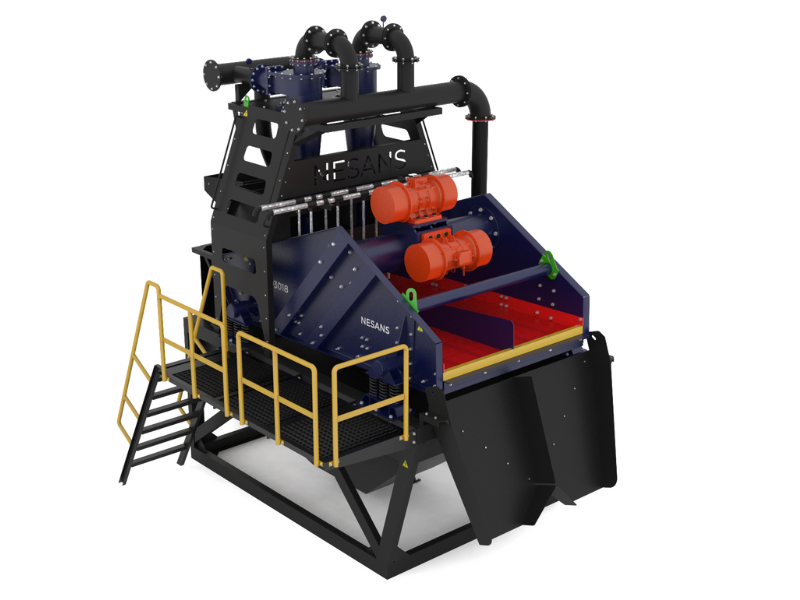

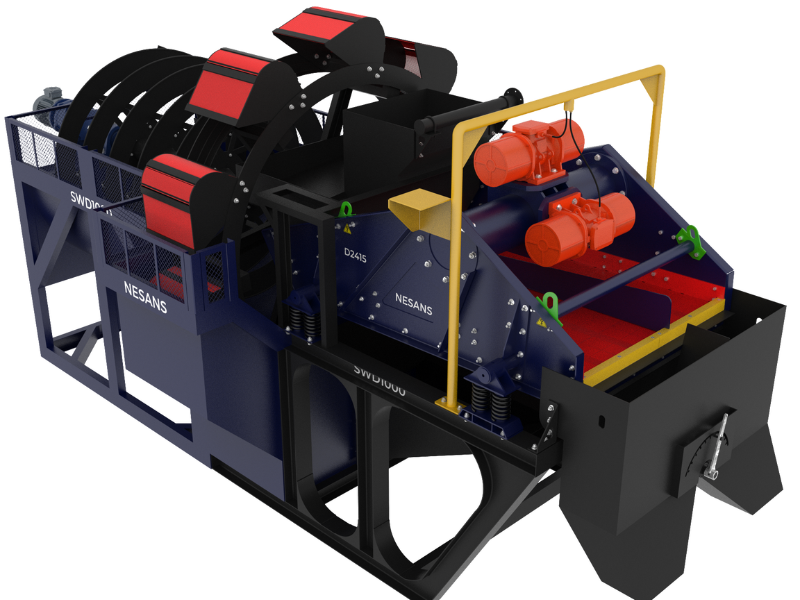

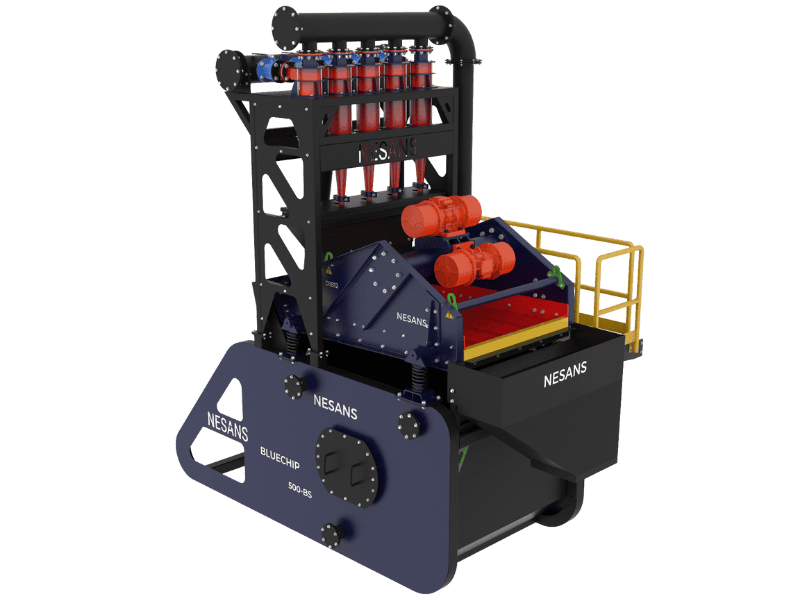

Product Gallery

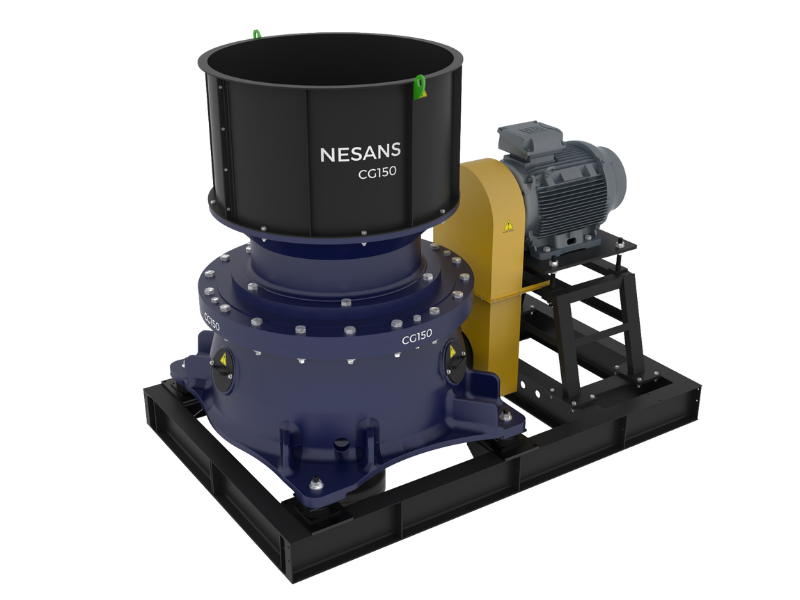

Relevant Products

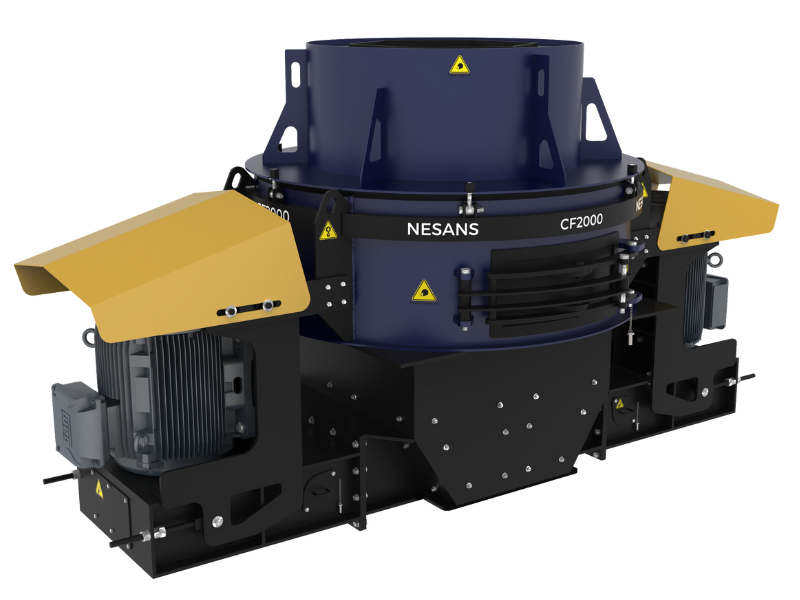

Cone Crusher

Learn More

Jaw Crusher

Learn MoreContact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.