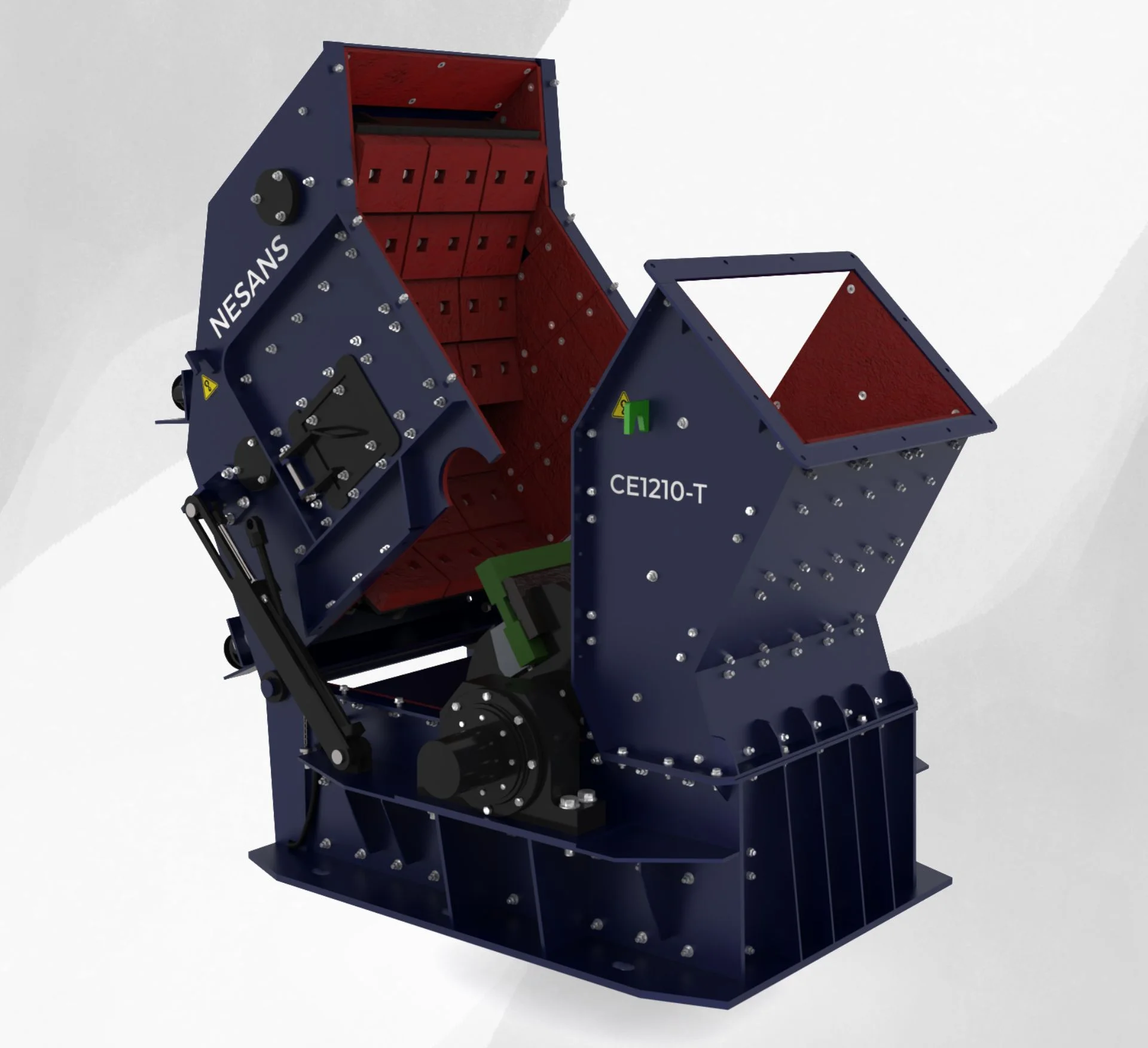

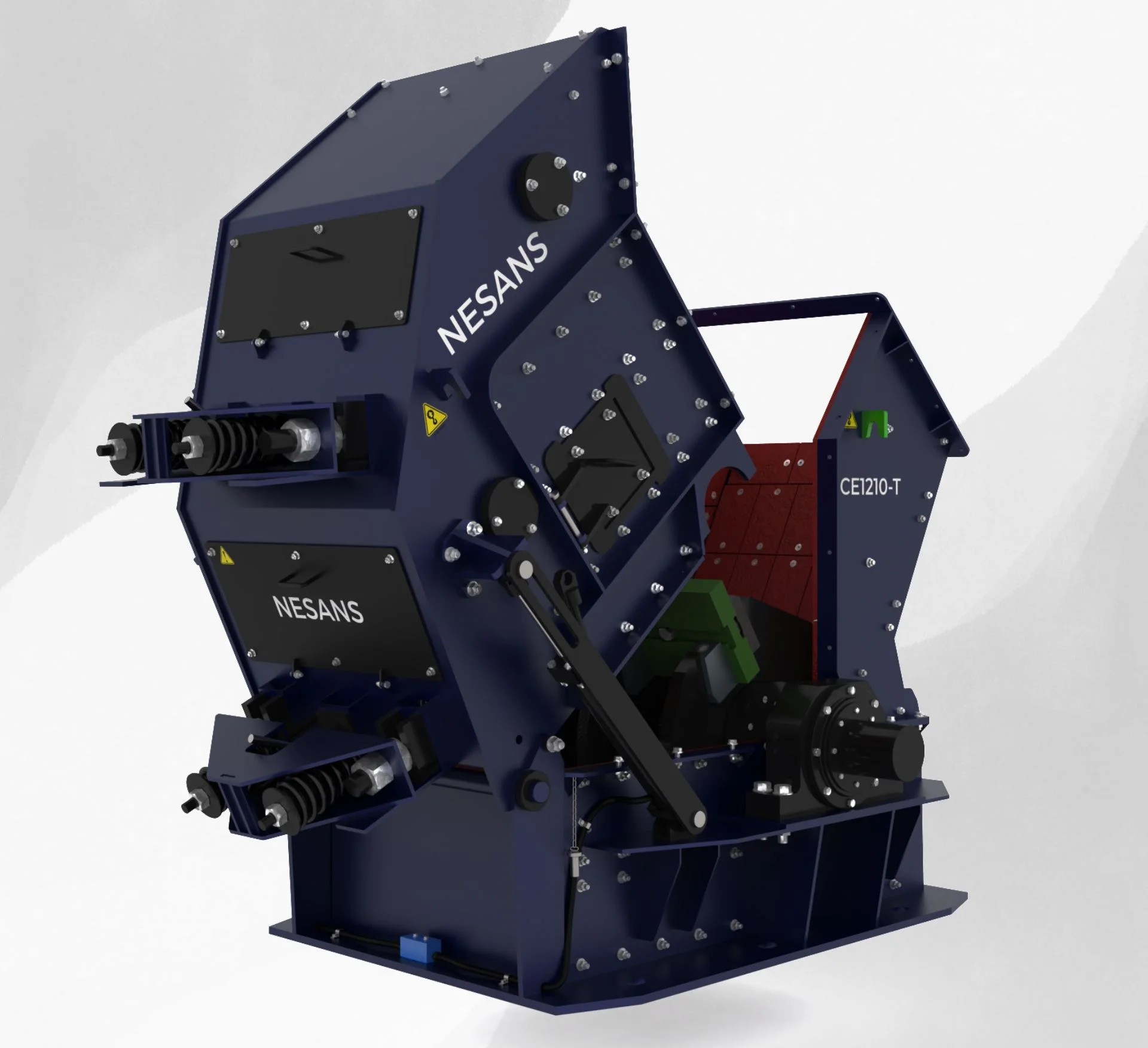

HSI Crushers - CE Series

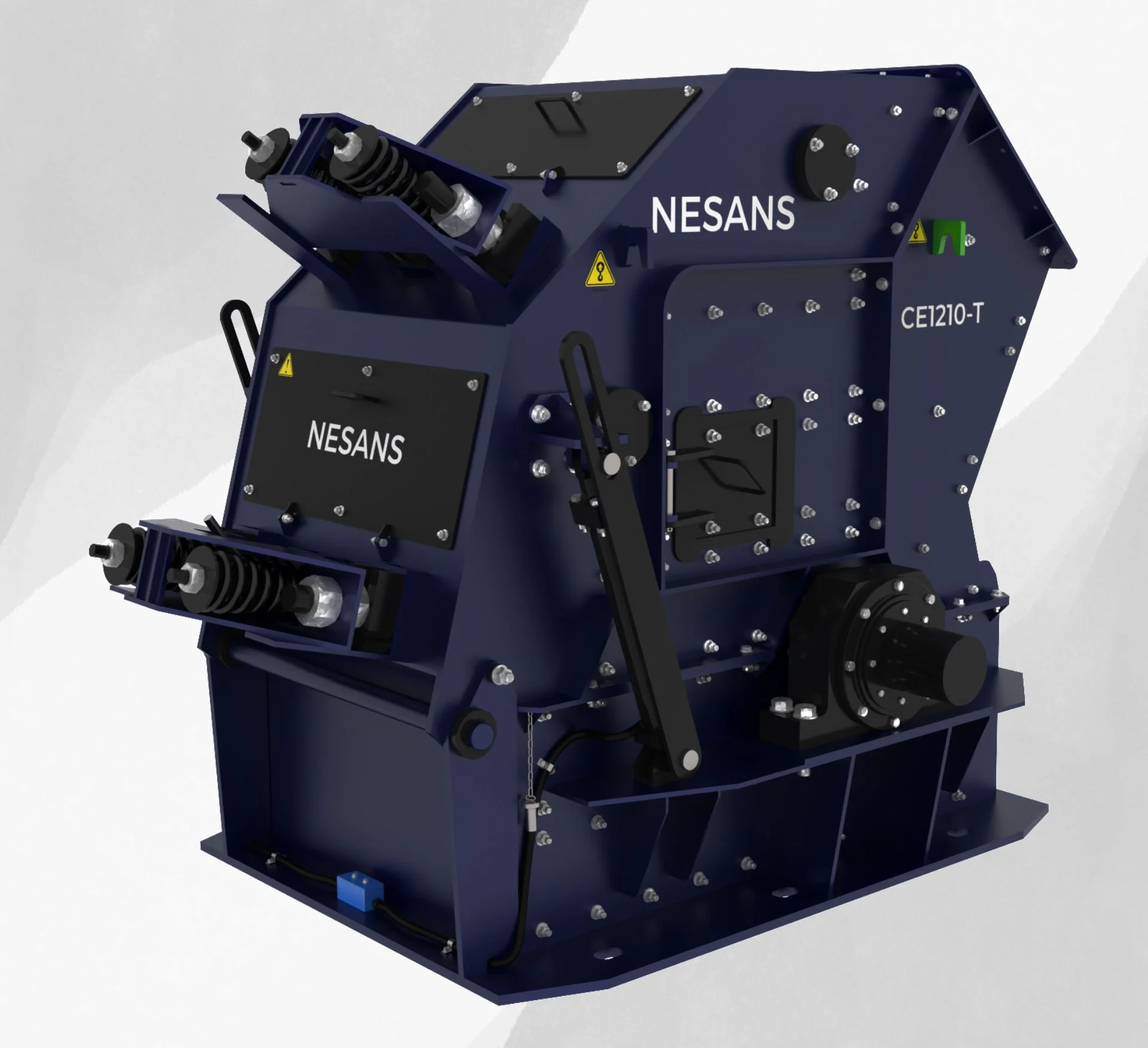

The Nesans CE Series Horizontal Shaft Impact (HSI) Crushers are specially designed to deliver superior crushing performance with unmatched efficiency and reliability. Built for heavy-duty operations, these crushers are ideal for secondary and tertiary crushing of a wide range of materials including granite, basalt, limestone, and recycled concrete. With a focus on producing well-graded, cubical end products, the CE Series is a perfect fit for modern aggregate production plants and infrastructure projects.

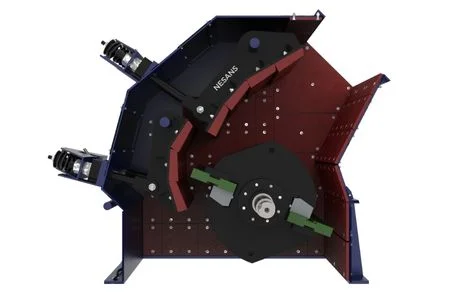

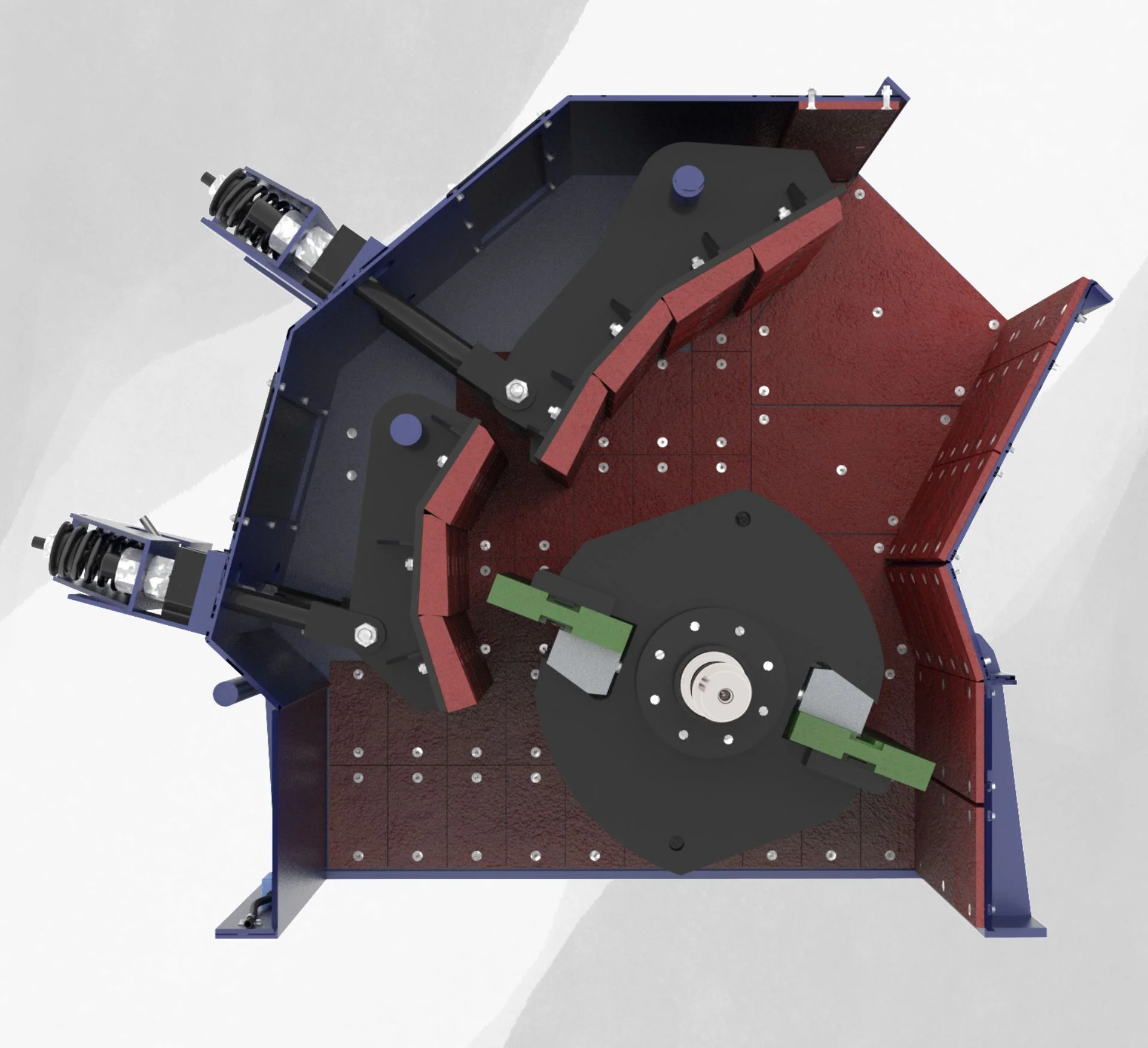

At the heart of the CE Series is a high-speed rotor system that delivers intense kinetic energy, allowing materials to be fragmented with precision. The crusher’s adjustable apron design and optimized chamber geometry ensure better control over product gradation and capacity. To enhance wear resistance and reduce operational costs, all key components are crafted from high-grade materials, while wear parts are strategically placed and easily replaceable.

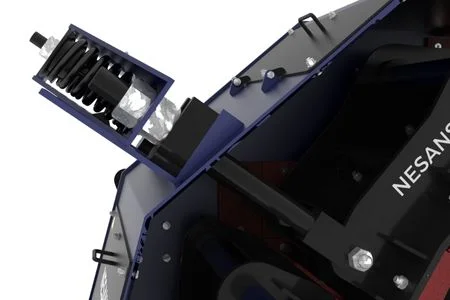

Nesans places a strong emphasis on user-friendly design and long-term value. The CE Series HSI Crushers come with hydraulic opening mechanisms, which simplify maintenance and reduce downtime significantly.

Applications:

How It Works

The Nesans CE Series HSI Crusher operates on the principle of impact crushing, where material is fed into the crusher chamber and accelerated by a high-speed rotor. As the rotor spins, it flings the material outward into a series of adjustable breaker plates (aprons). These plates are strategically positioned to absorb the impact and crush the material into smaller, uniform-sized particles. The design ensures optimal rock-on-metal contact, which not only maximizes reduction ratios but also produces well-shaped, cubical aggregates ideal for concrete and asphalt applications.

Once the material has been impacted and broken down, it falls through the crushing chamber and exits via the bottom opening. The crusher’s hydraulic adjustment system allows operators to fine-tune the position of the aprons, thereby controlling the product size and shape. This system, combined with easily replaceable wear parts and robust construction, ensures consistent performance, minimal downtime, and maximum productivity across a range of feed materials and operating conditions.

Features and Advantages

Specifications

| Model No. | Feed Opening (mm) | Max Feed Size (mm) | CSS Range (mm) | Motor Power (Kw) | Crusher Speed (rpm) | Crusher Weight (kg) | Capacity (mtph) |

|---|---|---|---|---|---|---|---|

| CE1210S | 400X600 | 200 | 20 - 50 | 55 | 900 | 4320 | 30-40 |

| CE3036S | 750X800 | 220 | 22 - 55 | 90 | 800 | 7240 | 75-100 |

| CE4230S | 1020X820 | 250 | 25 - 62 | 160 | 800 | 9500 | 110-150 |

| CE5252S | 1320X880 | 275 | 27 - 69 | 200 | 700 | 13110 | 165-200 |

| CE5263S | 1540X930 | 300 | 30 - 75 | 262 | 700 | 16050 | 220-250 |

| CE1210T | 400X600 | 30 | 10 - 15 | 55 | 900 | 4320 | 30-40 |

| CE3036T | 750X800 | 40 | 10 - 20 | 90 | 1000-1200 | 7240 | 75-100 |

| CE4230T | 1020X820 | 45 | 10 - 23 | 160 | 900-1100 | 9500 | 110-150 |

| CE5252T | 1320-880 | 50 | 10 - 25 | 200 | 900-1100 | 13110 | 165-200 |

| CE5263T | 1540X930 | 55 | 10 - 28 | 250 | 800-1000 | 16050 | 220-250 |

| Model No. | Feed Opening (in) | Max Feed Size (in) | CSS Range (in) | Motor Power (Hp) | Crusher Speed (rpm) | Crusher Weight (lb) | Capacity (stph) |

|---|---|---|---|---|---|---|---|

| CE1210S | 16X32 | 8 | 0.8 - 2 | 75 | 900 | 9523 | 33-44 |

| CE3036S | 30X32 | 8.8 | 0.86 - 2.1 | 120 | 800 | 15961 | 83-110 |

| CE4230S | 40X32.3 | 10 | 1 - 2.5 | 220 | 800 | 20944 | 121-165 |

| CE5252S | 52X34.6 | 11 | 1 - 2.7 | 250 | 700 | 28903 | 182-220 |

| CE5263S | 60.6X36.6 | 12 | 1.2 - 3 | 350 | 700 | 35384 | 243-276 |

| CE1210T | 16X32 | 1.2 | 0.5 - 0.6 | 75 | 900 | 9524 | 1.2 |

| CE3036T | 30X32 | 1.6 | 0.3 - 0.8 | 120 | 1000-1200 | 15961 | 83-110 |

| CE4230T | 40X32.3 | 1.8 | 0.3 - 0.9 | 220 | 900-1100 | 20944 | 121-165 |

| CE5252T | 52-34.6 | 2 | 0.3 - 1 | 250 | 900-1100 | 20903 | 182-220 |

| CE5263T | 60.6X36.6 | 2.2 | 0.3 - 1.1 | 350 | 800-1000 | 32384 | 243-276 |

Product Gallery

Relevant Products

FAQs

An HSI crusher (Horizontal Shaft Impact) is a versatile machine that can function as a primary, secondary, or tertiary crusher. Its main role is to take medium-sized, low-abrasive feed material and reduce it into a high-quality, final product. Unlike a jaw or cone crusher, which rely on compression, an HSI uses high-speed impact. This makes it a popular choice for crushing applications in quarrying and recycling where the desired output is a specific product shape (cubical) for use in concrete or asphalt.

At Nesans we deploy HSIs mainly as primary/secondary for limestone and softer rock, and as secondary in RMC (Ready-Mix Concrete) / RAP (Reclaimed Asphalt Pavement). For granite/basalt, we prefer jaw → cone (HSI only for select shaping where economics make sense).

Best on medium-soft to medium-hard stone (limestone, dolomite) and recyclables (concrete/asphalt). We don’t recommend HSIs as the main reducer on very abrasive granite/basalt unless blow-bar costs are acceptable and targets are modest.

- Blow Bars: These are the primary wear parts, mounted on the rotor, that strike the material at high speed.

- Breaker Plates/Aprons: Stationary plates inside the chamber that the material is thrown against for further crushing.

- Side Liners: Protective plates that line the inside walls of the crusher frame to prevent wear from ricocheting material.

Hardened alloy liners with profiles matched to your apron scheme. For clayey or recycling duties, use smooth/anti-pack profiles and accessible wear zones for quick swaps.

- Primary limestone: often open with a downstream screen.

- Secondary limestone & recycling: typically closed circuit to lock gradation and limit recirculating overs.

- Add pre-screening to bypass fines/clay; post-screening to split on-spec products and control recirculating load.

The final product size of an HSI crusher is controlled by adjusting the position of the breaker plates (also called aprons) relative to the rotor. The gap between the blow bars and the breaker plates determines how many times the material will be impacted before it can exit the chamber. A smaller gap leads to a finer product and a higher crushing ratio. The repeated impact and throwing action is what gives the final product its desirable cubical shape.

- Two-apron: simplicity and high throughput.

- Three-apron: adds a shaping stage for tighter gradation.

- Settings: wider gaps lift capacity and reduce fines; tighter gaps sharpen top size and shape at the expense of wear.

- Material Abrasiveness: The harder the material (e.g., granite), the faster the wear. Softer materials (e.g., limestone) cause less wear.

- Feed Size and Distribution: Irregular or oversized feed causes uneven stress and premature wear.

- Rotor Speed: Higher speeds increase impact force, which improves crushing but also accelerates wear.

- Rapid Blow Bar Wear: This is the most common issue. While blow bars are designed to be replaced, rapid wear is often due to an overly abrasive feed material. Consider using harder, more wear-resistant alloy blow bars or a different crusher type if the material is too abrasive.

- Reduced Product Size Consistency: As the blow bars and breaker plates wear, the final product shape and size can become inconsistent. Regularly inspect and adjust the gap between the rotor and the aprons to maintain a uniform output.

Material Buildup: Sticky or wet material can clog the crushing chamber. Ensure the material is as dry as possible and regularly inspect the chamber to prevent blockages.

The main difference lies in their crushing principle and the resulting product shape.

- HSI Crusher (Horizontal Shaft Impactor): Uses a horizontal rotor to strike and throw material against breaker plates. It's known for its high crushing ratio and ability to produce a cubical, well-shaped product, especially with less abrasive materials. It's a good choice for both primary and secondary crushing.

- VSI Crusher (Vertical Shaft Impactor): Uses a high-speed vertical rotor to accelerate material, which then impacts stationary anvils or a bed of material. This "rock-on-rock" crushing action is ideal for producing a very fine, uniform product and is often used in the final crushing stages (tertiary or quaternary). VSIs are particularly effective with highly abrasive materials.

Yes, an HSI crusher is highly effective for producing M-sand. It's often used in the tertiary stage of a crushing plant, where its ability to achieve a high crushing ratio and produce a consistent, cubical product makes it perfect for generating high-quality manufactured sand.

HSI crushers are popular in recycling because their design is more tolerant of a mix of materials. While they don't handle tramp iron as well as jaw crushers, their impact-based crushing is excellent for breaking down concrete and asphalt to produce usable aggregate.

Proper maintenance is essential for an HSI crusher. The key is to manage the wear parts:

- Regular Inspections: Frequently check the blow bars and breaker plates for wear. Rotating or flipping them can help extend their lifespan.

- Consistent Feeding: Avoid irregular feeding as it can cause unbalanced wear on the blow bars and rotor.

- Proper Lubrication: Adhere to the manufacturer's schedule for greasing and lubrication of all bearings.

- Adjustments: Regularly check and adjust the gap between the rotor and the aprons to maintain the desired product size and crushing ratio

The choice depends on your specific needs:

- Material: For hard, abrasive materials (e.g., granite), start with a jaw crusher and then use a cone crusher for further reduction. For softer, less abrasive materials (e.g., limestone), an HSI crusher can be an excellent all-in-one solution for both primary and secondary stages.

- Desired Output: If you need a very fine, cubical product (like manufactured sand), a cone crusher or HSI crusher is your best bet. A jaw crusher's product is typically more angular.

- Cost: While an HSI crusher often has a lower initial price, its wear parts can have a higher maintenance cost per ton if used on the wrong material. A cone crusher may have a higher upfront cost but lower wear parts expenses in abrasive applications.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.