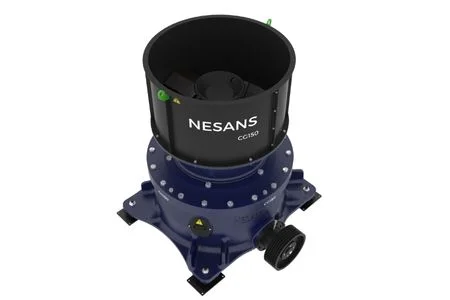

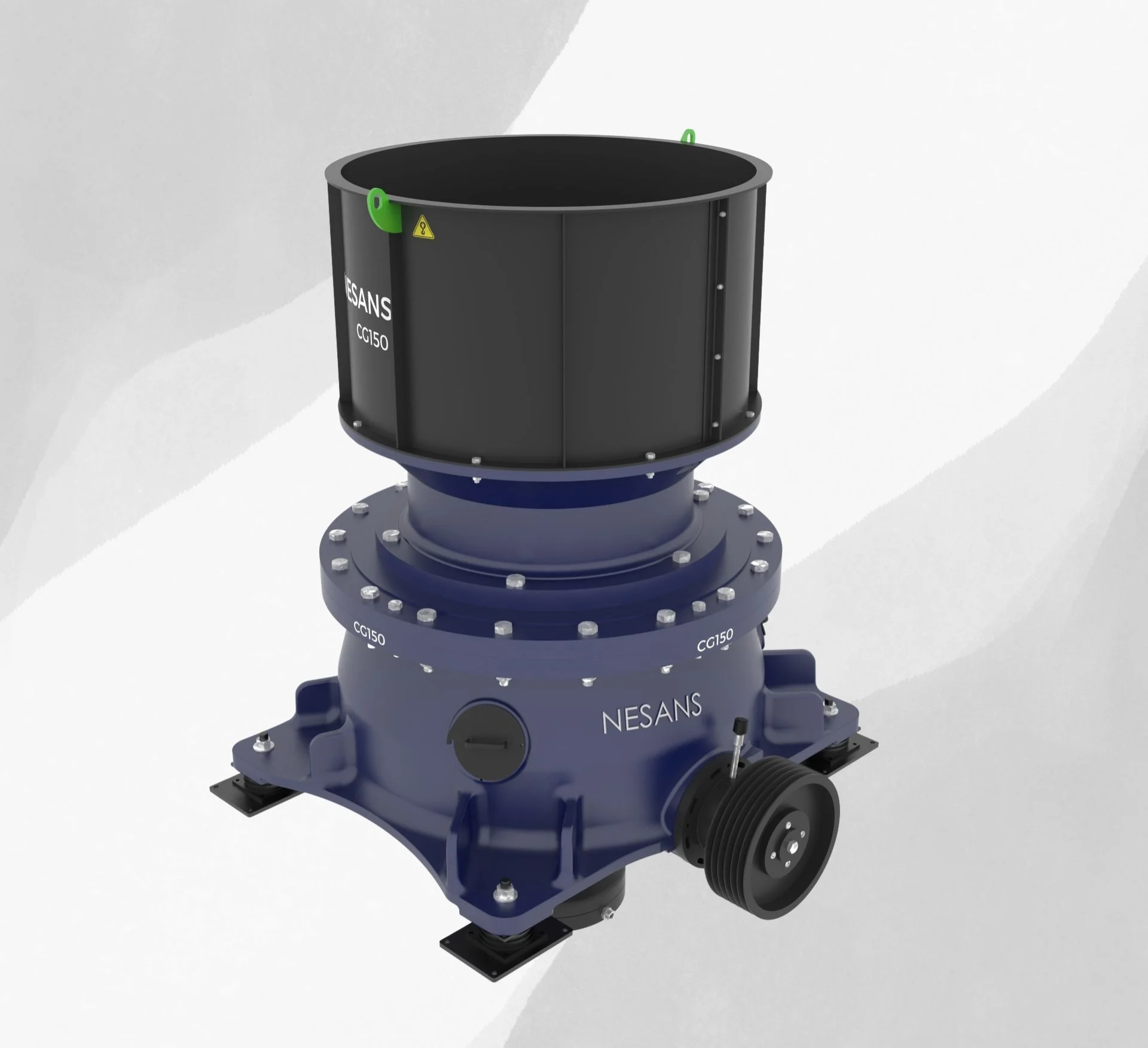

Cone Crushers - CG Series

The CG Series Cone Crusher is engineered for high-capacity performance and precise crushing across demanding applications. Its advanced chamber geometry and balanced design ensure consistent product shape and superior reduction. With optimized speed and stroke, it delivers efficient throughput while maintaining energy efficiency.

Built for versatility, the CG Series excels in secondary and tertiary crushing, handling a wide range of materials with ease. Whether in mining, quarrying, or aggregates production, it adapts seamlessly to site conditions. Its rugged build guarantees stable operation even under the toughest workloads.

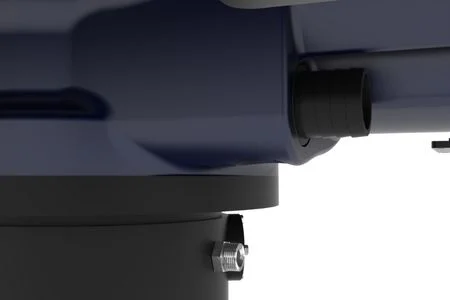

Ease of maintenance, simplified access to critical components, and reduced downtime make the CG Series a reliable partner for continuous production. Heavy-duty parts ensure long equipment life and lower operating costs. This combination of performance, durability, and serviceability sets it apart in the crushing industry.

Applications:

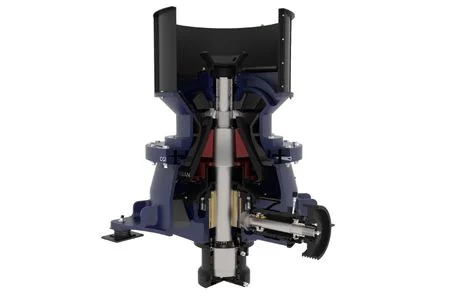

How It Works

The CG Series Cone Crusher operates on the principle of compression crushing. Material is fed into the crushing chamber where it is compressed between a rotating mantle and a stationary concave liner. As the eccentric motion of the main shaft causes the mantle to gyrate, the material is progressively crushed to smaller sizes.

The crushed material moves downward through the narrowing chamber as it gets reduced in size, until it reaches the desired output dimension and exits through the bottom. This continuous process ensures uniform product gradation and high reduction efficiency. The precisely engineered chamber and control systems allow for consistent performance and minimal operational interruptions.

Features and Advantages

Specifications

| Model No. | Feed Opening (mm) | Max Feed Size (mm) | CSS Range (mm) | Motor Power (Kw) | Crusher Weight (kg) | Capacity (mtph) |

|---|---|---|---|---|---|---|

| CG150 | 185 | 150 | 24-35 | 90-135 | 10200 | 90-200 |

| CG150F | 90 | 50 | 4-12 | 90-135 | 10200 | 65-110 |

| CG250 | 225 | 200 | 24-35 | 165-210 | 14100 | 150-310 |

| CG250F | 85 | 60 | 4-12 | 165-210 | 14100 | 90-130 |

| Model No. | Feed Opening (in) | Max Feed Size (in) | CSS Range (in) | Motor Power (Hp) | Crusher Weight (lb) | Capacity (stph) |

|---|---|---|---|---|---|---|

| CG150 | 7.5 | 6 | 0.94-1.38 | 120-180 | 22487 | 99-220 |

| CG150F | 3 | 2 | 0.16-0.47 | 120-180 | 22487 | 72-121 |

| CG250 | 9 | 8 | 0.94-1.38 | 220-280 | 31085 | 165-341 |

| CG250F | 3.3 | 2.4 | 0.16-0.47 | 220-280 | 31085 | 99-143 |

Product Gradation Curves

Particle size distribution at different Closed Side Settings (CSS)

Product Gallery

Relevant Products

Vertical Shaft Impact Crusher

Learn More

Horizontal Shaft Impact Crusher

Learn More

Jaw Crusher

Learn MoreFAQs

A cone crusher is typically a secondary, tertiary, or quaternary crusher. Its primary role is to take the material that has already been crushed by a primary crusher (like a jaw crusher) and further reduce it to a specific size and shape. Cone crushers are excellent for processing hard and abrasive materials like granite, basalt, and ore. They are crucial for producing the final, high-quality aggregates used in construction projects, such as for roads, buildings, and concrete.

The main cone crusher parts that require regular attention and replacement are the mantle and the concave. Other crucial components include the main shaft, eccentric bushing, and the hydraulic system.

Cone crushers are the go-to for hard and abrasive materials. They are best suited for materials that are too tough for an HSI crusher, such as granite, basalt, quartzite, and various types of ore.

Cones improve shape when choke-fed with a well-graded feed and the right chamber. Running too open, starved, or with the wrong profile increases elongated particles. For premium cubicality, pair a cone with a VSI downstream.

Both cone crushers and VSI crushers are used for tertiary crushing and aggregate production, but they operate differently and have distinct advantages:

- Cone Crusher: Uses compression to crush material. It's best suited for hard, abrasive materials like granite and is highly effective at producing a consistent product shape.

- VSI Crusher: Uses impact (rock-on-rock or rock-on-steel) to crush material. It is the preferred choice for producing a very high-quality, perfectly cubical product and is often used in the final stage of M-sand and aggregate production.

The main advantage is the superior cubical product it produces. The crushing action within the chamber leads to a more uniform, well-shaped aggregate with fewer elongated or flat pieces. This cubical shape is highly valued in the construction industry for producing high-strength concrete and quality asphalt.

For maximizing a cone crusher's efficiency, the best practice is choke feeding which means keeping the crushing chamber full of material. This practice offers several benefits:

Maximizes Throughput: A full chamber leads to a higher crushing capacity (tons per hour) and more efficient use of power.

Improves Product Shape: When the chamber is full, the material is crushed against itself (rock-on-rock crushing), which produces a more uniform and desirable cubical product.

Reduces Wear: Choke feeding ensures that the wear parts like the mantle and concave wear evenly, extending their service life and lowering operational costs.

- Upstream: Pre-screen to remove material already at or below target; size apertures relative to target CSS/product.

- Downstream: Allow for surge and a recirculating load typical for your spec (design conveyors/screens so the cone isn’t starved). A small surge bin between screen and cone helps smooth flow.

- Spring Cone Crusher: This is a traditional design that uses a system of springs for overload protection. If an uncrushable object (tramp iron) enters the crushing chamber, the springs compress to allow it to pass. They are generally simpler and more cost-effective.

- Hydraulic Cone Crusher: This is a modern type that uses a hydraulic system for both setting adjustment and tramp release. This offers more precise control over the closed side setting (CSS) and allows for safer, faster clearing of the crusher in case of a jam. While the initial cone crusher price for a hydraulic model is higher, it often leads to better performance and reduced downtime.

When choosing a cone crusher, consider these key factors:

- Feed Size: What is the maximum size of the material coming from your primary crusher? Ensure the cone crusher's feed opening can handle it.

- Required Output Size: Cone crushers are defined by their closed side setting (CSS), which dictates the final particle size.

- Production Capacity: How many tons per hour (TPH) do you need to produce? This will determine the size and model of the crusher you need.

- Material Hardness: For extremely hard materials common in the region, a robust hydraulic cone crusher with a strong crushing principle is often a better investment.

- Budget: The cone crusher price can vary significantly. Decide whether a brand-new or used cone crusher fits your budget.

The final product size is controlled by adjusting the Closed Side Setting (CSS). The CSS is the minimum distance between the mantle and the concave at the discharge end of the crusher. By using a hydraulic adjustment system, an operator can precisely change this gap while the machine is running, allowing for immediate control over the final product's size. A smaller CSS results in a finer final product.

The most critical part of cone crusher maintenance is the lubrication system. A cone crusher generates significant friction and heat, and the lubrication system is essential for protecting key components like the main shaft, eccentric bushing, and gears. Regular checks of oil levels, pressure, temperature, and filter cleanliness are non-negotiable. Using the manufacturer's recommended lubricant is also a must to ensure the correct viscosity and additives are used.

- Aggregate Production: It is the standard for producing high-spec aggregates for concrete and asphalt from quarried rock.

- Mining Operations: Used for secondary crushing of ore to liberate valuable minerals before grinding and processing.

- Manufactured Sand (M-Sand): Many modern crushing plants use cone crushers in their tertiary stage to produce manufactured sand, a key component in today's construction market.

- Slag and Recycling: They are also used to crush tough materials like slag and recycled concrete to create reusable aggregates.

- The two main wear parts on a cone crusher are the mantle and concave. Knowing when to replace them is crucial for maintaining efficiency and preventing damage. Key indicators include:

- Uneven Wear Patterns: Check for "ski-slope" wear on the mantle or excessive wear in specific zones. This can indicate an issue with feed size or distribution.

- Reduced Throughput: A noticeable drop in the machine's crushing capacity (e.g., a 10% drop in TPH) is a strong sign the wear parts are past their prime.

- Visual Inspection: Physically inspect the thickness of the mantle and concave. When the thickness at the bottom of the liner approaches 1 inch, it's generally time to schedule a replacement.

- It's important to replace both the mantle and concave at the same time to ensure the crushing chamber has the correct geometry for efficient crushing.

Proper maintenance is crucial for a cone crusher's longevity and performance that include:

- Choke feeding: Always ensure the crusher is choke-fed with material to maximize efficiency and reduce uneven wear and tear on the mantle and concave.

- Lubrication: A reliable lubrication system is vital. Regularly check oil pressure, flow, and temperature to prevent overheating and premature wear of key bearings.

- Inspecting Wear Parts: Regularly inspect the mantle and concave for wear. Replacing these wear parts before they are fully worn out can prevent damage to more expensive components.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.