Radial Stacker Conveyors - RS Series

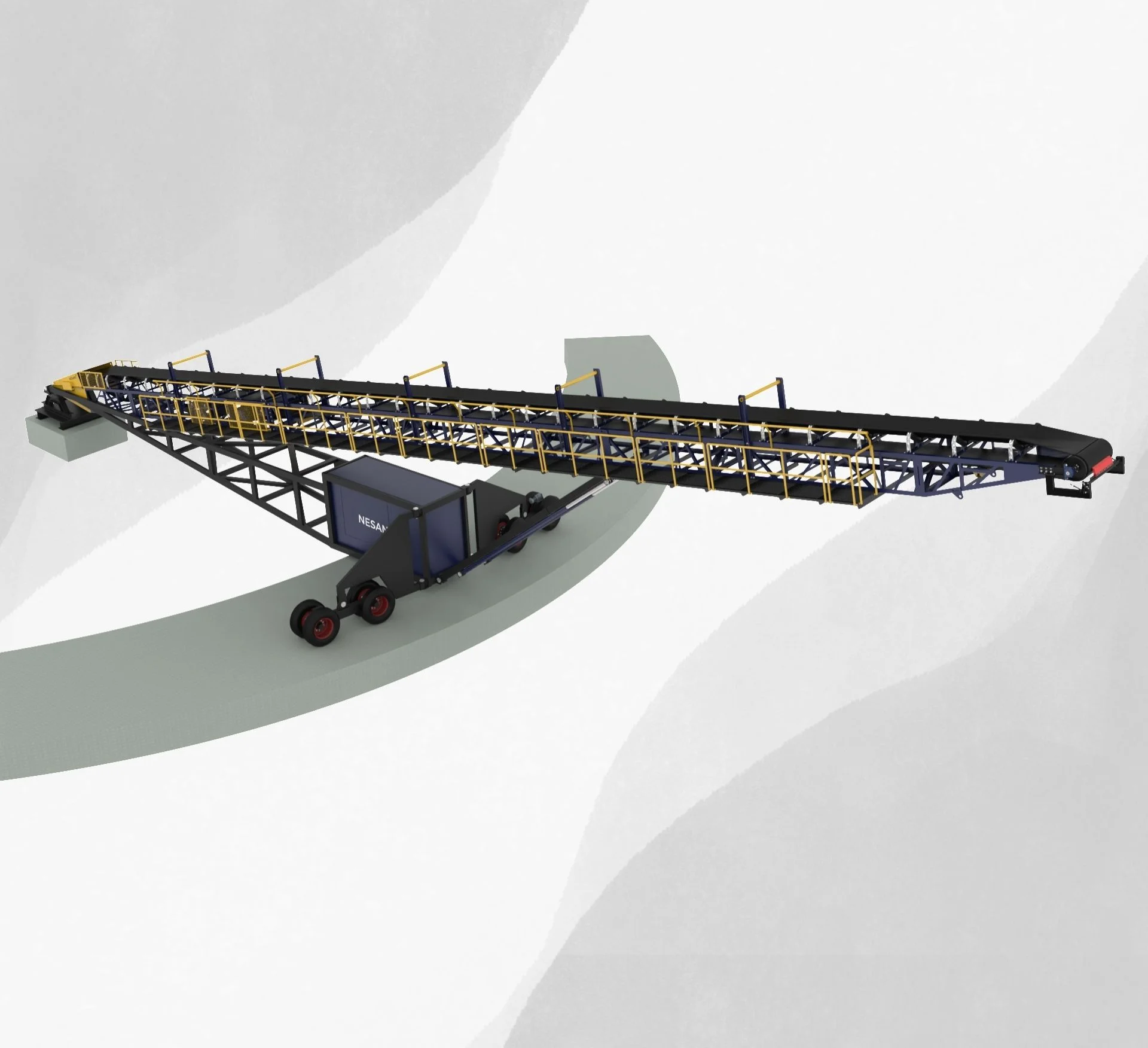

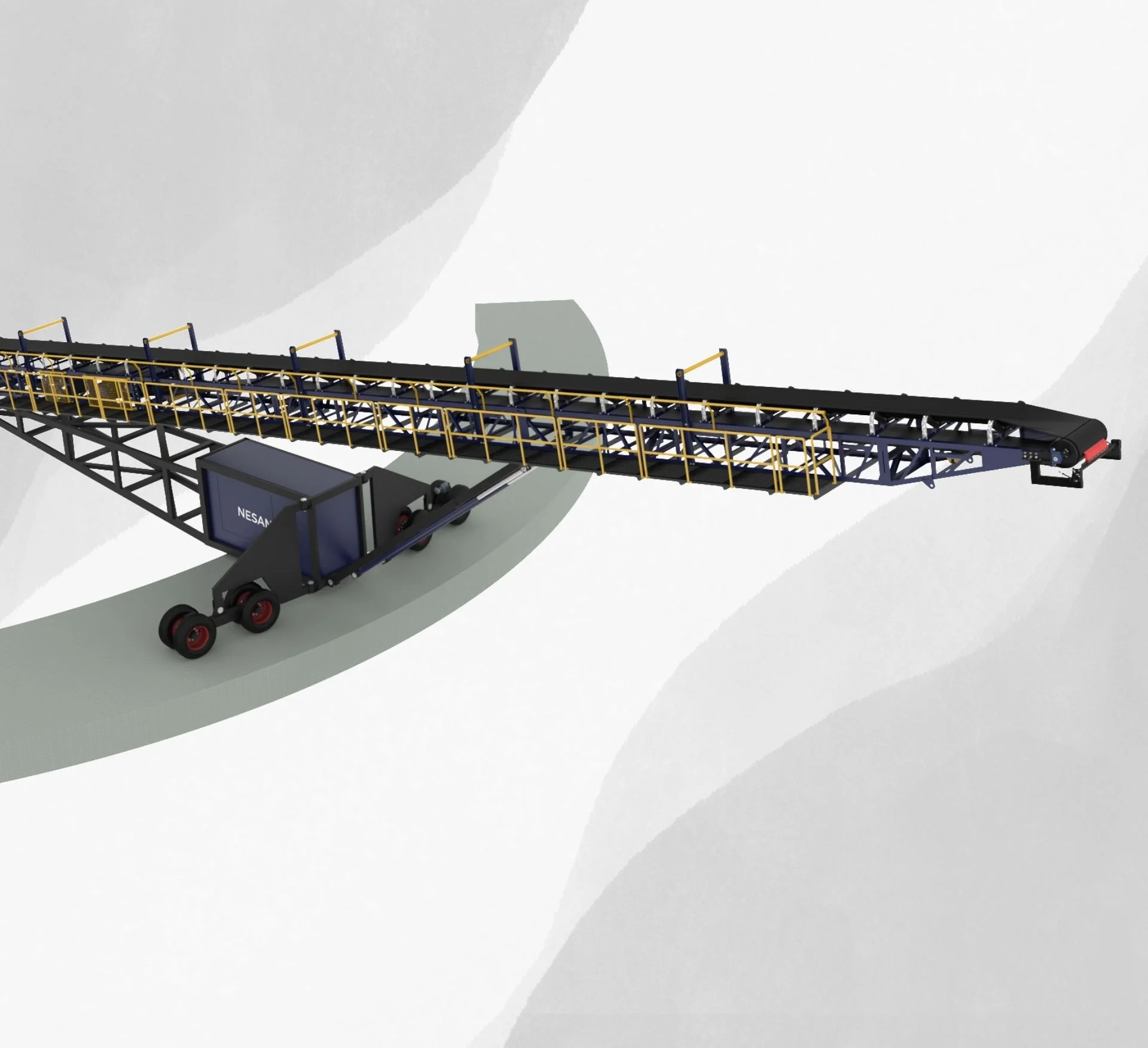

The Nesans RS Series Radial Stacker Conveyors are designed for automated material stockpiling with maximum efficiency and coverage. Built for high-volume material handling in mining, quarrying, and bulk storage applications, these conveyors reduce the need for multiple stacking points and help maximize yard space utilization. With their radial movement and adjustable height, RS Series stackers create large conical or trapezoidal stockpiles with minimal labor and equipment.

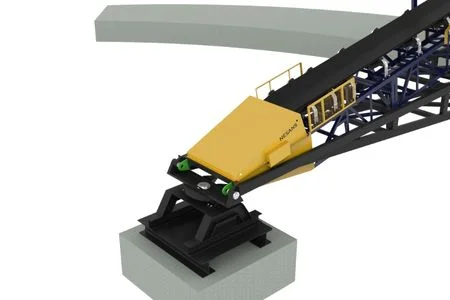

At the core of the system is a pivot-mounted structure combined with heavy-duty wheels and a hydraulic or electric drive system that allows for 180° radial movement. As the conveyor discharges material, the base moves along a circular track, allowing continuous stacking in a sweeping arc. The adjustable conveyor height ensures layering of material for uniform stockpile shape and optimal air drying, critical for consistent material quality.

Ideal for integrating into aggregate, mineral, and processed material workflows, the RS Series offers automated, consistent stacking with reduced spillage and downtime. Its rugged construction, weather-resistant components, and user-friendly control system make it a dependable solution for modern material handling and stockyard optimization.

Applications:

How It Works

The Nesans RS Series Radial Stackers operate by combining conveyor motion with radial movement to create uniform and high-capacity stockpiles. Material is fed onto the conveyor from a crusher, screen, or transfer point. As the belt conveyor moves the material to the discharge end, the entire structure pivots around a fixed point at the tail using a central pivot and wheeled support system.

The radial motion is powered by hydraulic or electric drives, allowing the stacker to sweep across an arc—typically up to 180°—creating a large, evenly layered stockpile. Simultaneously, the conveyor’s elevation can be adjusted to control pile height and maximize storage capacity. This dual motion (radial + vertical) enables the RS Series to stack in a variety of patterns, including conical, windrow, and trapezoidal formats.

Automation options further enhance the stacking process by enabling programmable stacking sequences, reducing the need for constant operator input. This results in efficient, continuous material stacking with minimal downtime and reduced handling costs.

Features and Advantages

Product Gallery

Relevant Products

FAQs

The Radial stacker combines conveyor motion with radial rotation. Material is fed onto the conveyor, and as it discharges, the entire stacker pivots around a central point on wheeled supports, creating a uniform stockpile.

They are widely used in quarrying, mining, power plants, cement, ports, and bulk terminals — anywhere large volumes of bulk material need efficient stockpiling.

Radial movement is powered by hydraulic or electric drives, allowing the stacker to sweep smoothly across an arc of up to 180°.

- Conveyor belt and rollers.

- Pivot system and wheel drives.

- Hydraulic/electric drive units.

By raising and lowering the conveyor during stacking, layers form evenly. This ensures uniform stockpile shape and better air drying, which is especially useful for sand, coal, and minerals prone to moisture.

Yes. Layered stacking with adjustable height allows better air circulation and drying in stockpiles, preventing issues like excess moisture or material compaction.

By sweeping across a 180° arc and adjusting height, a single radial stacker can replace multiple fixed conveyors or loaders, maximizing stockyard utilization.

Yes. Depending on the sweep angle and height settings, the RS can build conical, trapezoidal, or windrow stockpiles.

With programmable stacking sequences, the stacker can automatically move through preset arcs and elevations, ensuring uniform piles without constant operator input.

- Fixed stacker: Creates a single cone pile at one point.

- Radial stacker: Sweeps across an arc to create larger, layered, and uniform piles without relocation.

Instead of creating multiple small cone piles, the radial stacker sweeps through an arc to form one large, evenly layered stockpile, reducing rehandling and maximizing yard coverage.

It eliminates the need for operators to constantly move conveyors or loaders, since one radial stacker covers the area of multiple fixed conveyors.

Loaders consume fuel, require skilled operators, and create dust when stacking. Radial stackers are automatic, energy-efficient, and create uniform piles with less dust and lower costs.

- Daily: Inspect wheel track for debris.

- Weekly: Check wheel alignment and lubrication.

- Monthly: Grease pivot bearings and inspect hydraulic/electric drive components.

It depends on your requirement:

- Choose a Radial Stacker if you need to create large stockpiles across a wide area (quarry yards, bulk terminals, mining).

- Choose a Telescopic Conveyor if you need flexible discharge at varying distances in a compact site (multi-stage crushing, recycling, or plant-to-plant transfers).

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.