Belt Conveyors - NT Series

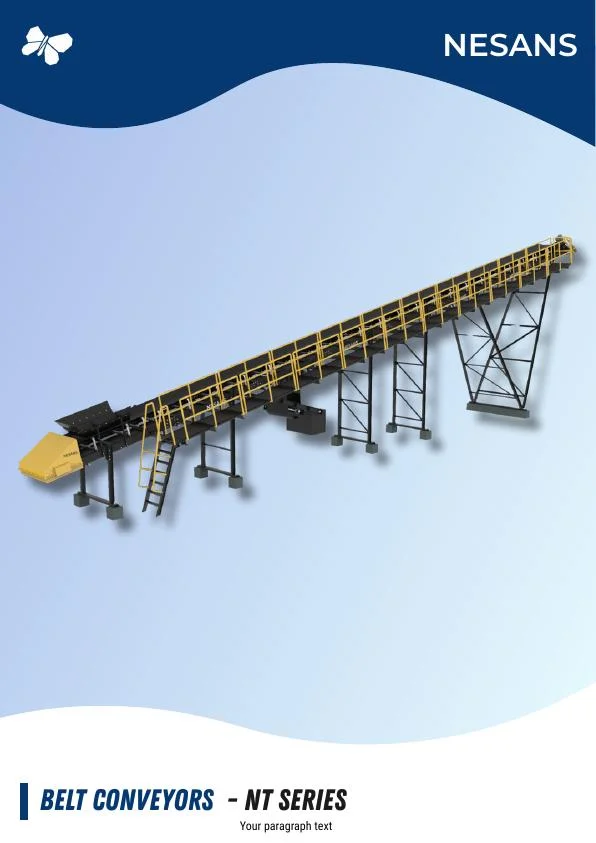

The Nesans NT Series Belt Conveyors are engineered for continuous material handling across crushing, screening, and washing operations. Designed with precision and durability in mind, these conveyors ensure efficient transfer of bulk materials like aggregates, minerals, and sand with minimal spillage and wear. With configurations available for both horizontal and inclined conveying, the NT Series offers flexibility to fit various plant layouts.

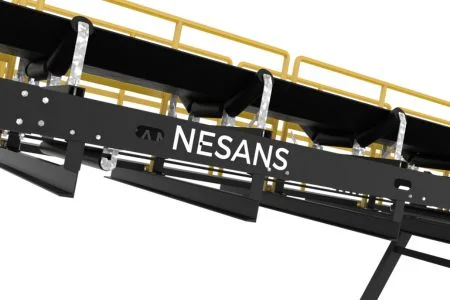

Each conveyor features a robust frame structure, wear-resistant rollers, and a high-strength belt designed for long service life. Integrated walkways, safety rails, and access ladders provide secure maintenance access, while tensioning and tracking systems ensure smooth and consistent operation under varying load conditions.

Whether you’re feeding a crusher, stockpiling finished product, or transferring between equipment, Nesans Belt Conveyors provide a dependable, low-maintenance solution built to keep your plant running efficiently and safely.

Applications:

How It Works

The Nesans NT Series Belt Conveyors operate on a simple yet highly efficient principle of continuous material transport using a moving belt supported by rollers. Material is loaded onto the belt via a feed chute or hopper. As the belt moves, powered by an electric motor and gearbox assembly, it carries the material along the length of the conveyor to its discharge point—whether that’s a stockpile, bin, or another processing machine.

The conveyor system uses idlers and return rollers to support the belt and maintain proper alignment. A tensioning mechanism ensures the belt remains taut during operation, while tracking systems prevent it from drifting off-course. For inclined installations, cleats or side guides can be added to keep material from slipping back. The combination of sturdy structure, precise engineering, and optional accessories makes the NT Series ideal for handling a wide range of materials in challenging industrial environments.

Features and Advantages

Product Gallery

Relevant Products

Telescopic Conveyor

Learn More

Radial Stacker

Learn MoreFAQs

A belt conveyor is a continuous material-handling system where a moving rubber or fabric belt, supported on idlers or rollers, carries bulk material from one point to another. The belt runs over pulleys at each end, driven by an electric motor.

It is typically used to connect stages such as:

- Crusher → Screen

- Screen → Washer

- Washer → Stockpile/Bin

- Sorting Line → Storage

It is designed for sand, aggregates, crushed stone, minerals, compost, recyclables, and industrial bulk solids. Its sturdy frame and engineered components make it suitable for heavy-duty and continuous operation.

The conveyor uses idler sets and return rollers to support the belt, while tensioning and tracking systems keep the belt taut and prevent it from drifting off-course.

Yes. For inclined installations, cleated belts or side guides can be fitted to prevent material from slipping back during transport.

- Conveyor belt.

- Idlers and return rollers.

- Drive pulley lagging.

- Scrapers/cleaners at loading points.

It is designed with modular components — belts, rollers, and pulleys can be replaced without dismantling the entire structure.

A tensioning mechanism keeps the belt properly taut, preventing slippage and ensuring long life of both the belt and rollers.

Belt conveyor includes tracking systems that automatically correct belt drift and maintain proper running alignment.

They use tensioning and tracking systems that automatically adjust to keep the belt aligned and taut, even when feed conditions change.

They are versatile and can be used for:

- Feeding crushers with raw material.

- Stockpiling finished products like sand or aggregates.

- Transferring material between screens, washers, or other processing equipment.

Emergency stop pull-cords, guards for pulleys and drives, belt covers, and lockout/tagout systems for maintenance.

- Belt drifting: Adjust tracking or idlers.

- Spillage at loading point: Install skirt boards or seals.

- Slippage: Re-tension the belt or check drive pulley lagging.

- Daily: Check belt alignment, spillage, and tension.

- Weekly: Inspect rollers, pulleys, and scrapers.

- Monthly: Check gearbox oil and drive motor condition.

Yes. The NT Series is available in different lengths, widths, and configurations (fixed, mobile, or radial stacker types) depending on your plant requirements.

Contact Us

Want to Know More? Need a Quote? Please Complete the form below and our Sales Engineer will follow up shortly.