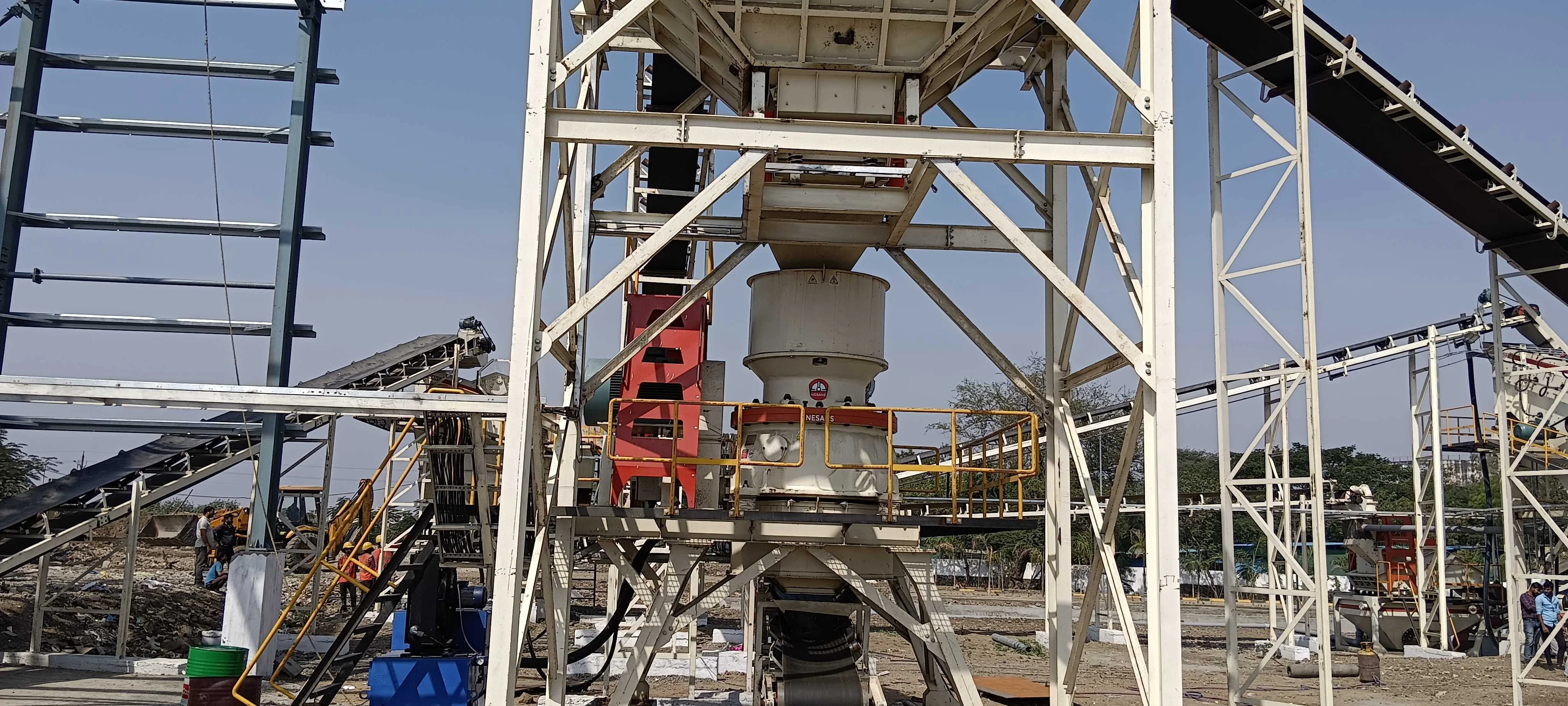

About This Installation

This 500 TPH belt feeder keeps a steady stream of sand & gravel flowing into a 300 TPH Nesans sand‑washing plant on the Gulf Coast. Its frame is built from AR‑350 plate, the head shaft spins on oversized SKF bearings with a triple‑seal pack, and every detail is aimed at shrugging off coastal dust and humidity.

• 1.2 m × 8 m belt, rated to 750 TPH surges

• Modular impact beds every metre protect belt & idlers

• Hydraulic VFD lets operators dial feed from the control room

• Dual belt cleaners cut carry‑back and downstream water use

The result? A rugged, low‑maintenance link between raw feed and clean product—purpose‑built for the heat, humidity, and abrasive materials typical of Texas and Louisiana sites.